Expansion fixture

A technology of expansion clamps and clamping bodies, which is applied in the field of expansion clamps, and can solve the problems of complex replacement of workpieces, complex structures, and affecting processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

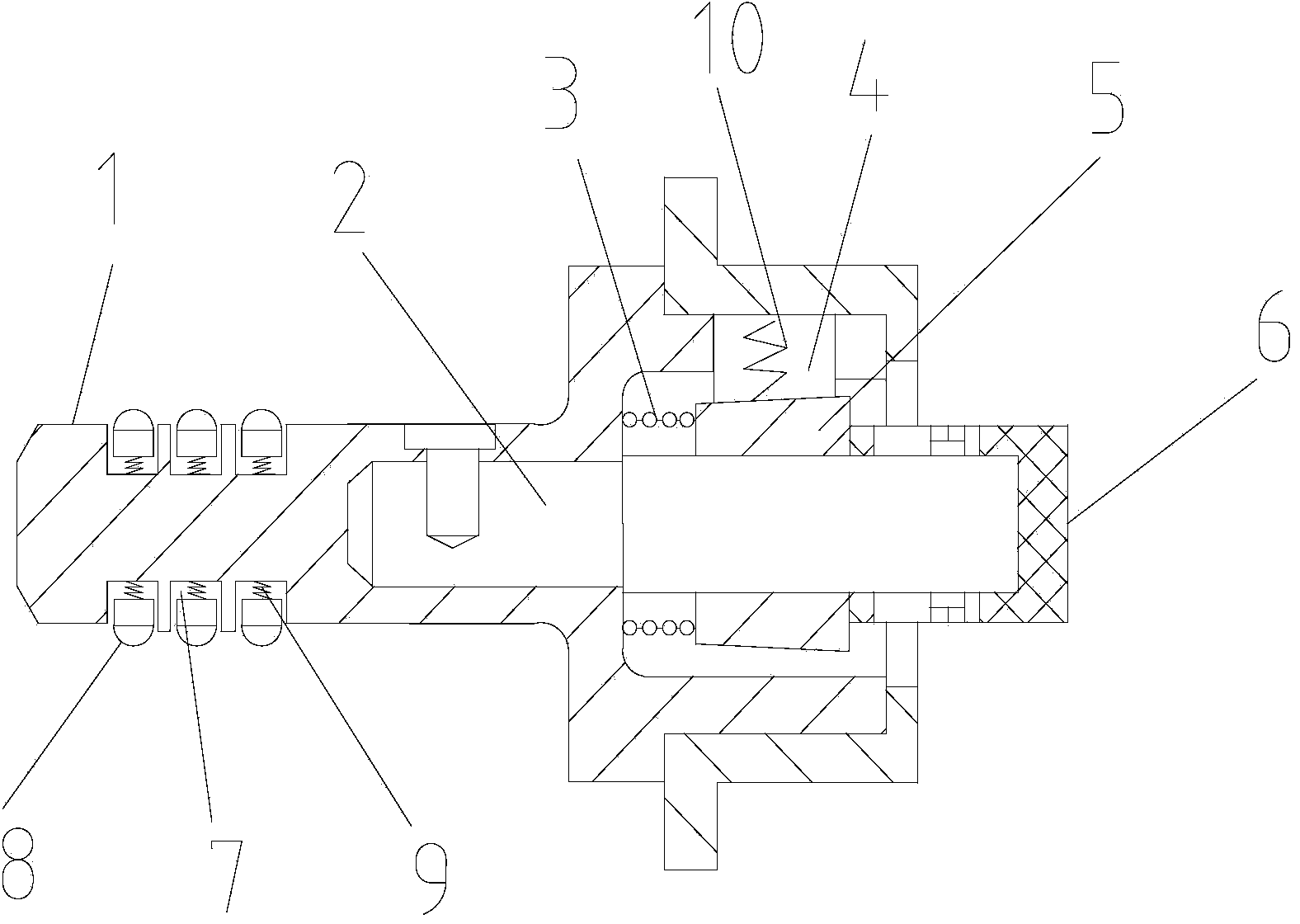

[0011] As shown in the figure, the expansion fixture includes clamp body 1, guide post 2, abdication spring 3, expansion block 4, taper sleeve 5, and top sleeve 6. The front end of clamp body 1 is provided with a groove 7, and in the groove 7 There is a protrusion 8, and the protrusion 8 and the groove 7 are connected by a spring 9, and the fixture is installed in the Morse taper hole at the front end of the lathe, and the protrusion 8 withstands the Morse taper hole under the action of the spring 9 to improve the The fastness of the connection between the clamp body 1 and the Morse taper hole reduces vibration. There is a cavity behind the clamp body 1. The guide post 2 is set in the clamp body 1. The abdication spring 3 and the taper sleeve 5 are set on the guide post 2. One end of the spring 3 is set on the inner wall of the cavity of the clamp body 1, and the other end is set on the front end of the taper sleeve 5. After the abdication spring 3 is processed and the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com