Heating end and heater

A heating head and plug body technology, applied in the direction of induction heating, induction heating devices, etc., can solve the problems that affect the normal welding work, inconvenient use, insufficient heating head, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

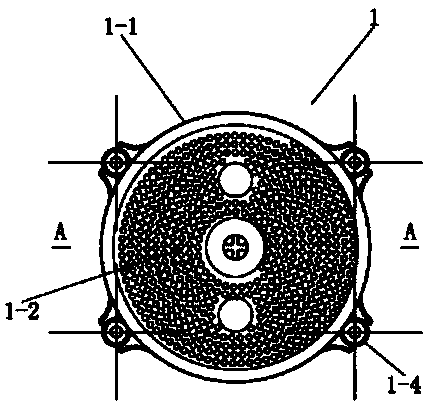

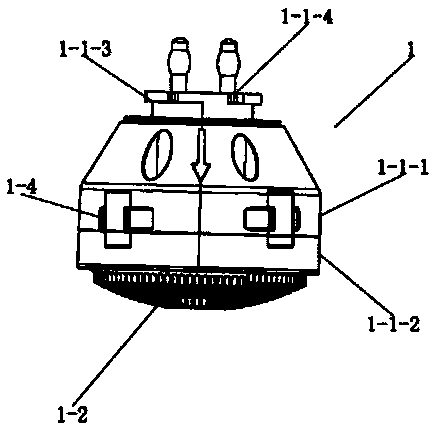

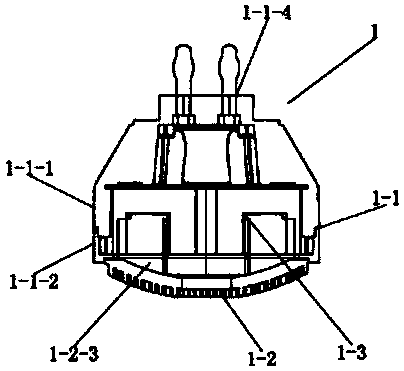

[0172] like Figure 1 to Figure 3 as shown,

[0173]This embodiment provides a heating head 1, which includes a casing 1-1, and a locking fitting part 1-1-3 is arranged on the back of the casing 1-1.

[0174] Various improvements as this embodiment are described below.

[0175] Such as Figure 20 to Figure 21 as shown,

[0176] The locking fitting part 1-1-3 includes a locking neck 1-1-3-1 and a locking head 1-1-3-2.

[0177] The locking neck 1-1-3-1 is an annular body extending backward from the rear surface of the housing 1-1.

[0178] The locking head 1-1-3-2 is a plurality of arc-shaped flanges extending radially outward from the rear edge of the outer surface of the locking neck 1-1-3-1.

[0179] The locking heads 1-1-3-2 are evenly distributed in the circumferential direction of the locking neck 1-1-3-1.

[0180] The arc length of the locking heads 1-1-3-2 is less than or equal to twice the arc distance between two adjacent locking heads 1-1-3-2.

[0181] There ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com