Novel transmission clamp

A fixture and a new type of technology, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of laborious operation, insufficiency of large workpiece clamping, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

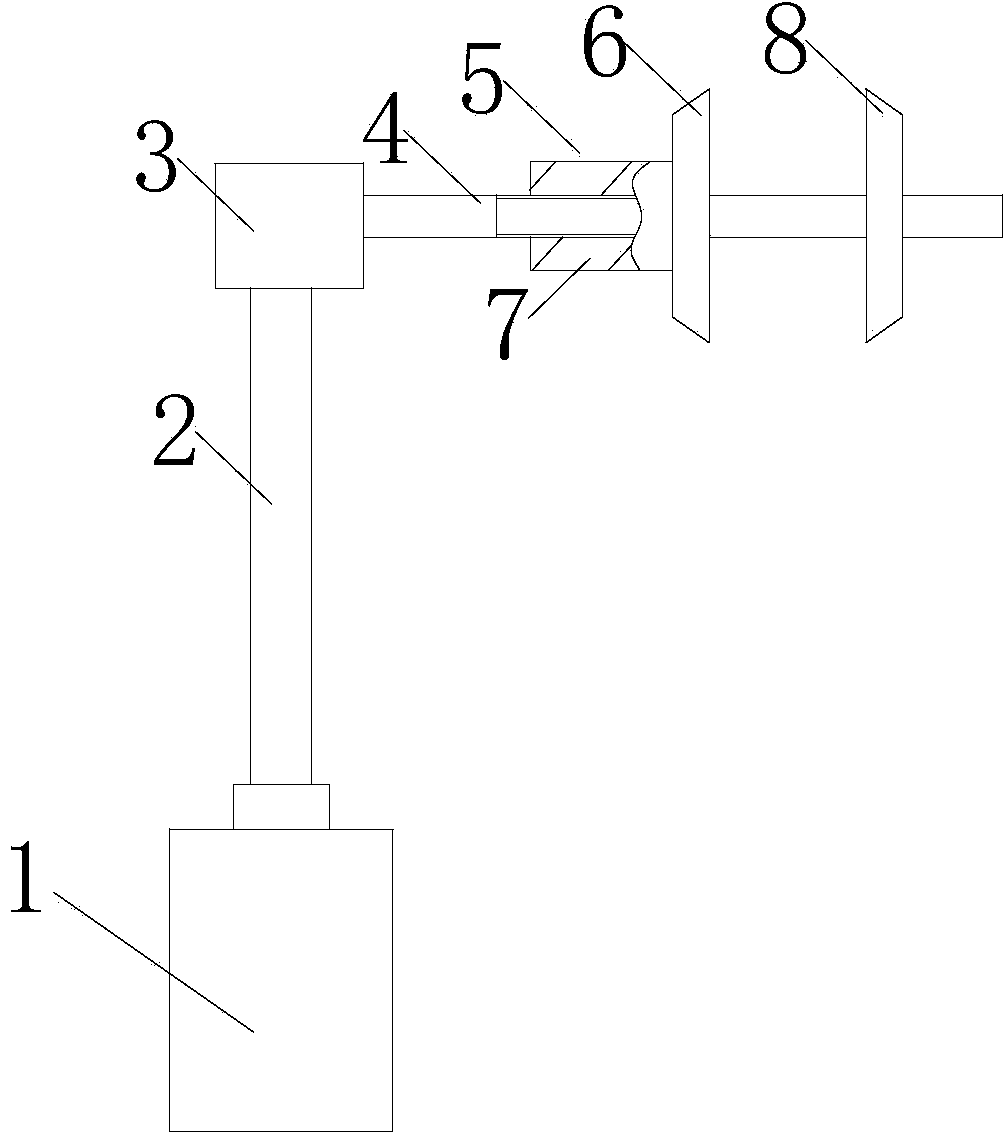

[0012] Such as figure 1 As shown, the novel transmission fixture includes a motor 1, which is connected to the vertical first transmission shaft 2 of the motor; one end of the first transmission shaft 2 is connected to the bevel gear steering box 3; the bottom of the bevel gear steering box is provided with a The support seat that workbench connects; Described bevel gear steering case 3 one side is provided with the second transmission shaft 4 of horizontal; The threaded part in the center of the transmission shaft, and the nut seat 7 used in conjunction with the threaded part) The end of the second transmission shaft 4 is detachably connected with the first block 6; the screw auxiliary nut seat 7 is connected with the second block 8.

[0013] The rotation of the motor drives the first transmission shaft to rotate, which is transmitted to the second transmission shaft with a screw pair in the center through the steering box. Workpiece clamping between the block and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com