Driving mechanism with positioning function

A technology of transmission mechanism and function, applied in the direction of transmission device, mechanical equipment, linear motion axis, etc., can solve the problems of improving operation convenience, performance and application range, insufficient versatility, short life and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

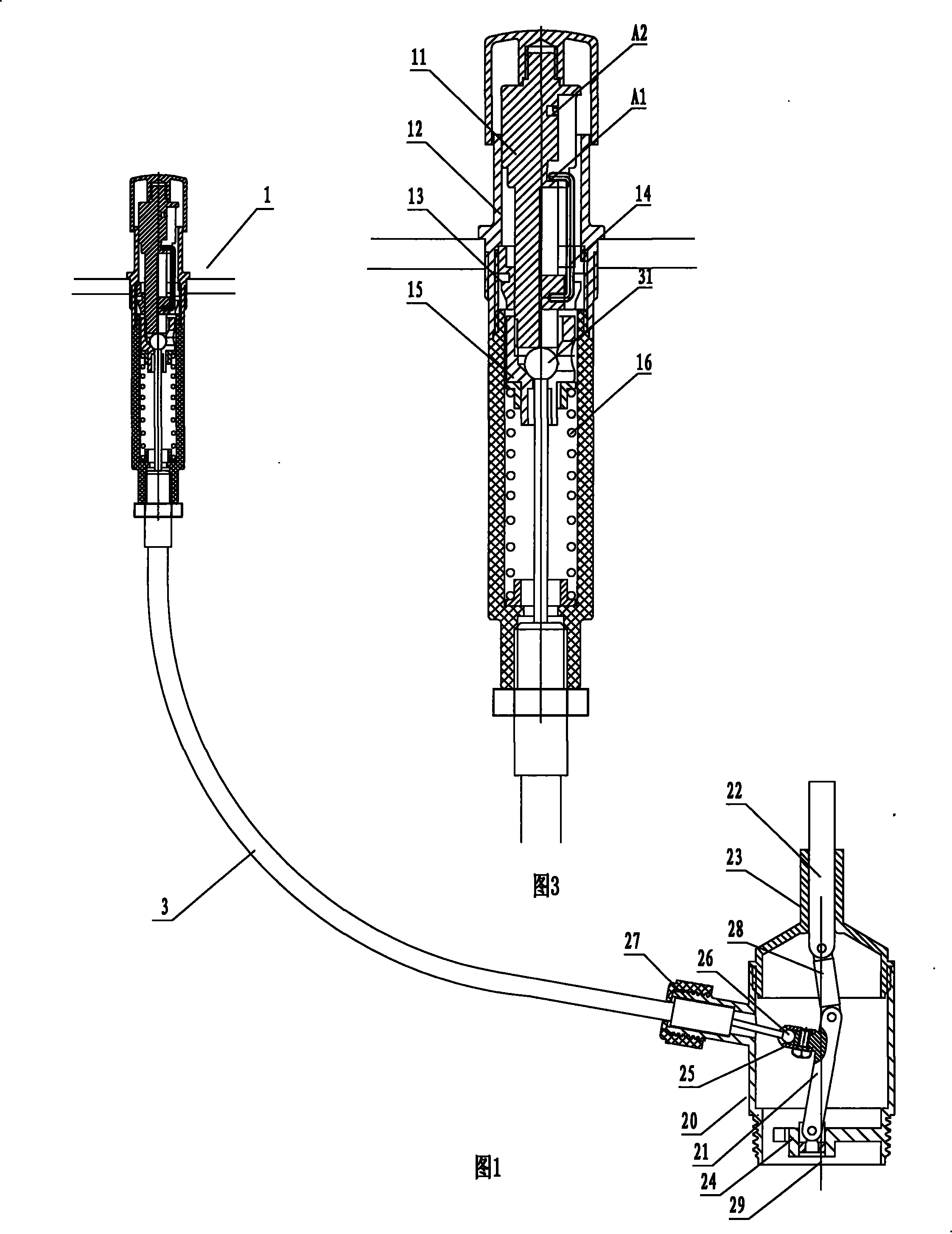

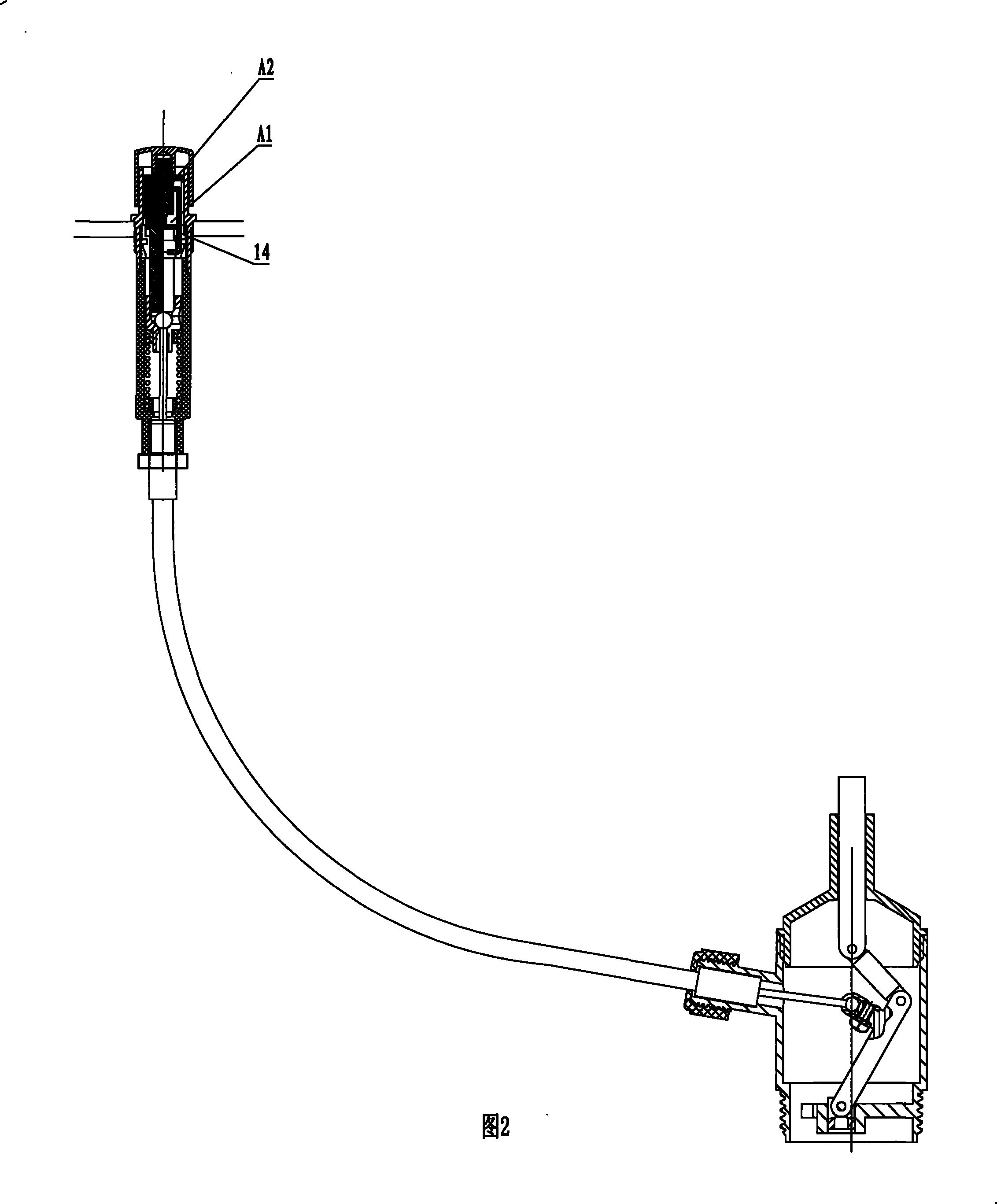

[0010] Refer to attached figure 1 , 2 , 3. The present invention includes a push-type switch 1. The switch is provided with a sliding shaft 11 and a fixed sleeve 12 penetrating up and down. The sliding shaft 11 can slide in the fixed sleeve 12. Generally, the operation of the sliding shaft is realized by pressing. In the axial direction of the sliding shaft, the sliding shaft is provided with two limiting positions A1 and A2 at different heights, which are formed by grooves penetrating the surface of the sliding shaft, and a plunger 13 is fixed inside the fixed sleeve 12, The fixed sleeve 12 and the plunger 13 can be a unified body, or parts that can be set separately, and the plunger 13 is fixed with a retaining hook 14, such as figure 1 , 2 As shown, when the sliding shaft is pressed to slide in the fixed sleeve in the axial direction, the hook part of the stop hook also slides in the groove. When the hook part of the stop hook is hooked at the limit position A1, the coop...

Embodiment 2

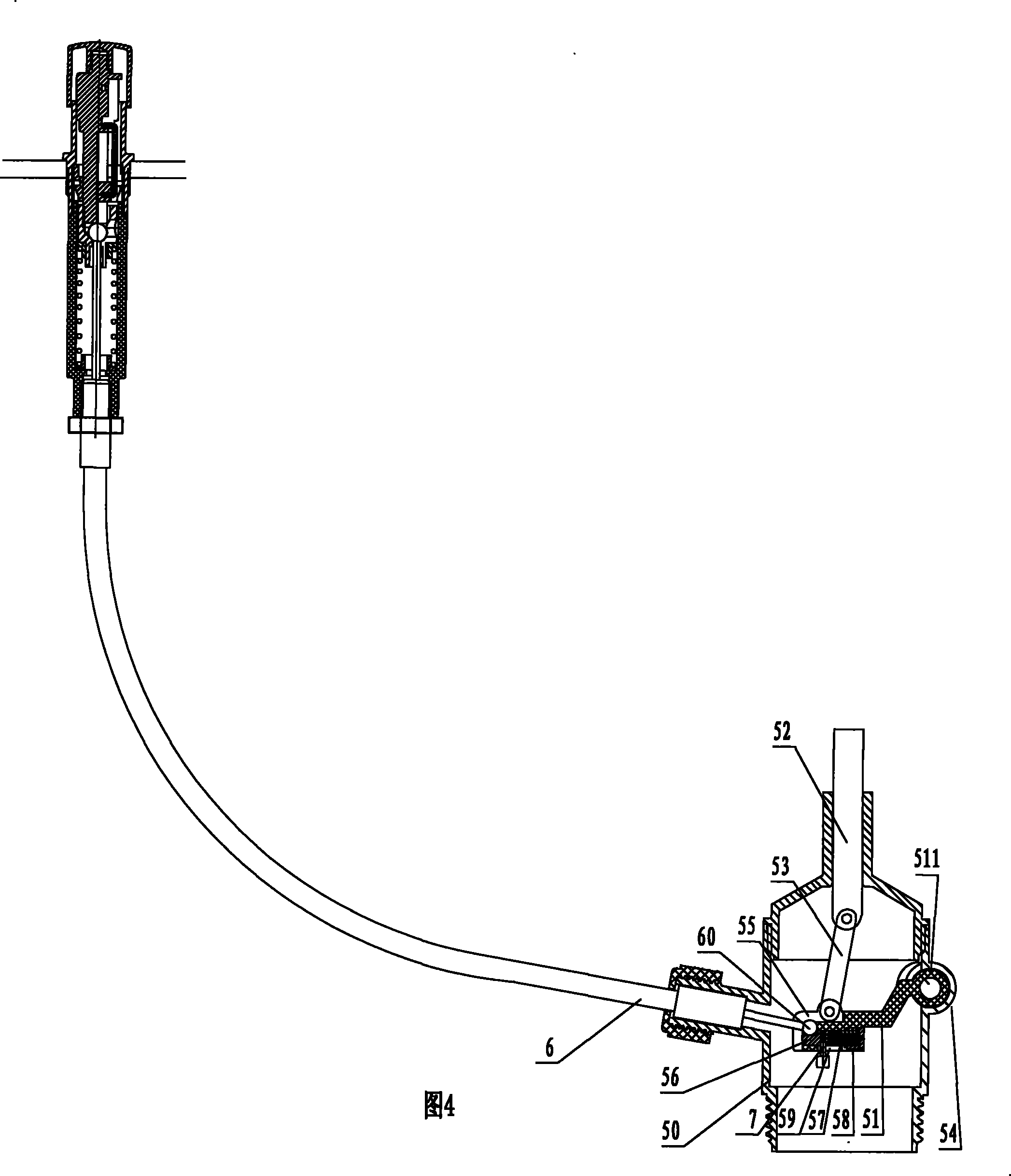

[0020] Refer to attached Figure 4 , 5 . In this embodiment, the connection scheme of the linkage mechanism, the installation body and the connecting steel wire is changed, and the others are the same as in Embodiment 1.

[0021] The connecting rod mechanism is also provided with an intermediate connecting rod 53 between the first connecting rod 51 and the second connecting rod 52, and the mounting body 50 of the connecting rod mechanism is provided with a connecting rod outside the side of the intermediate connecting rod 53 facing away from the connecting steel wire 6. The hinged connection seat 54 of the mechanism.

[0022] The end 511 of the first connecting rod is hinged on the hinged connecting seat 54, the head of the first connecting rod is provided with a connecting seat 55, and the end of the connecting steel wire is provided with a connecting head 60, and the connecting head is rotatably The card is set in the connecting seat.

[0023] The connecting seat is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com