Cable High Speed Printer

A printing machine and printing mechanism technology, applied in typewriters, printing, etc., can solve problems such as complex installation structure, difficult to guarantee printing quality, asynchronous movement of printing wheel and cable, etc., and achieve the effect of comprehensive position adjustment function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

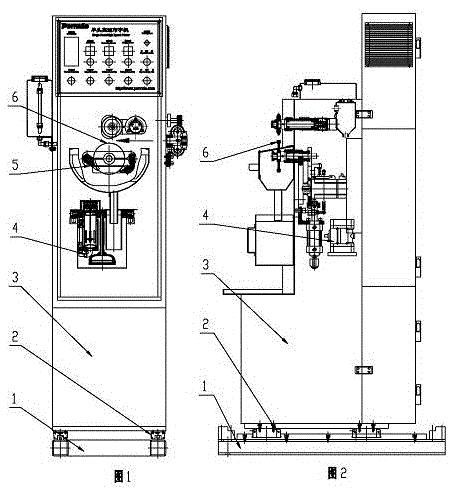

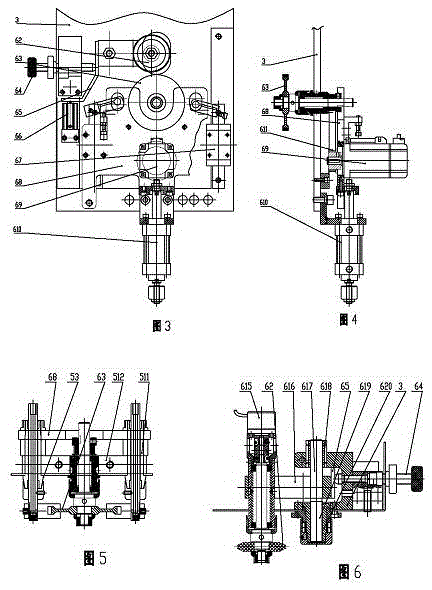

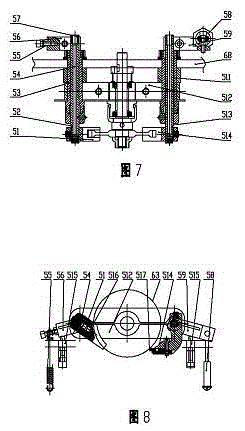

[0034] exist Figure 1 to Figure 2 In the cable high-speed printing machine shown, the ink supply device 4, the printing mechanism 6, and the inkjet assembly 5 are supported on the frame 3, and the produced cables pass through the printing mechanism 6, and the inkjet assembly 5 is used by the printing mechanism 6. The ejected ink prints the relevant specifications and parameters of the cable on the surface of the cable. The ink supply device 4 provides the ink used for printing to the inkjet assembly 5. A cable is arranged on the frame 3 on the inlet side of the printing mechanism 6. Guide mechanism, the control panel of the printing machine is above the printing mechanism 6, and the electric control system of the printing machine is placed in the frame 3 behind the control panel; the frame 3 is movably supported on the bottom frame 1 through the guide rail 2, and the guide rail 2 is General-purpose linear guide rail, certainly also can be general-purpose linear bearing plus g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com