Segmented cleaning instrument

A cleaning device and multi-segment technology, which can be used in cleaning devices, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of difficulty in starting points and ends, time-consuming, and difficulty in connecting areas, and achieve enhanced effect and stable weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

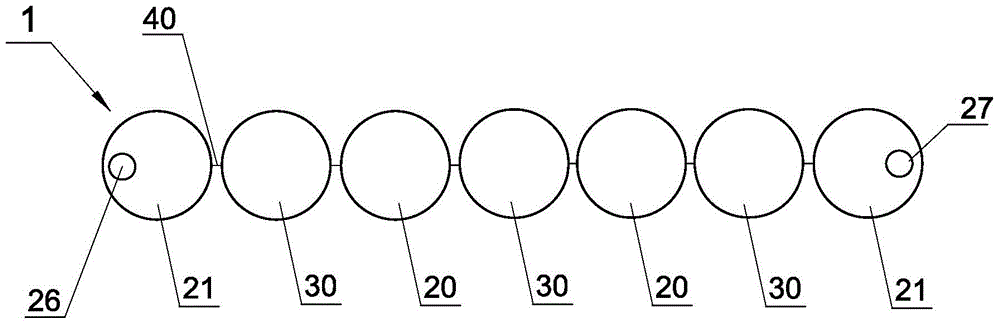

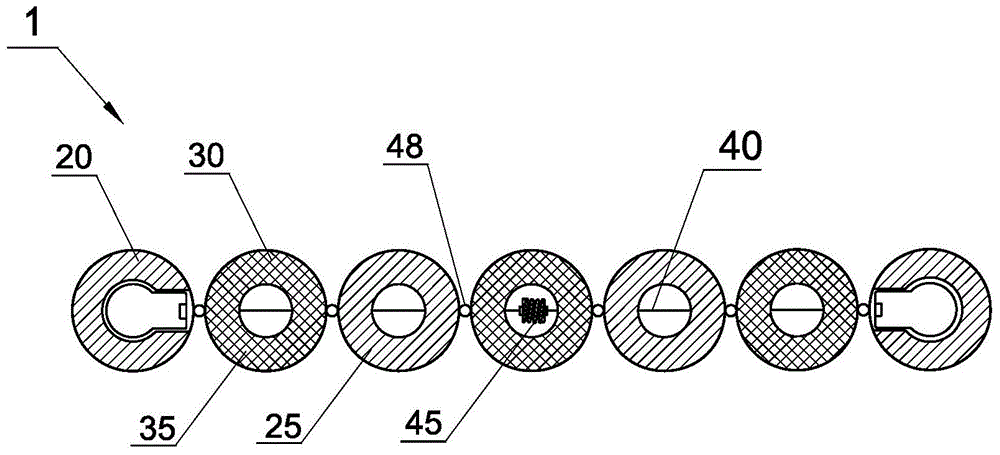

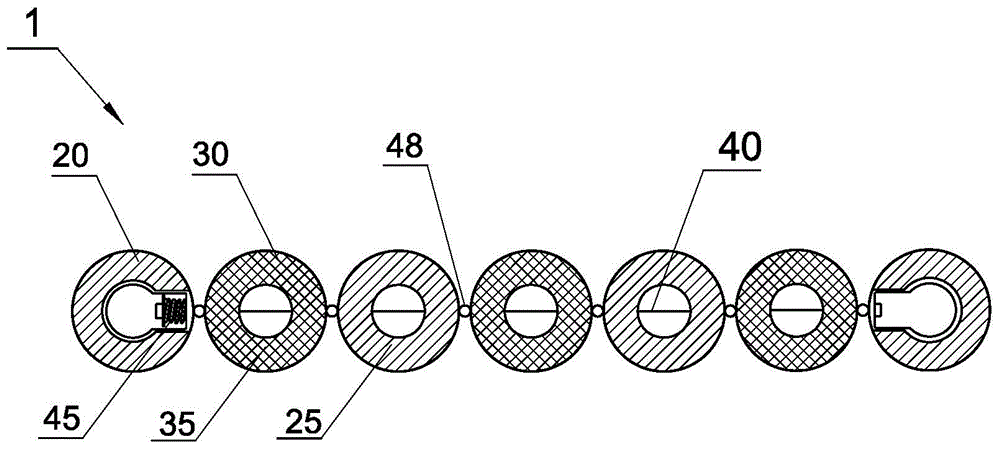

[0032] figure 1 A preferred embodiment of the cleaning device 1 according to the invention is shown in side view. The cleaning device is provided with a terminal cleaning member 21 on which detection marks 26, 27 are placed; in addition, an internal first cleaning member 20 and a second cleaning member 30 are provided, and the first cleaning member 20 and the second cleaning member 30 have different physical properties so that they can ensure that the different surfaces of the cleaning members 20 and 30 adhere to the walls of the transport channel. In a preferred embodiment of the invention, the second members 20 are characterized in that they are attached to the walls of the transport channel on a small surface. These are usually members made of sponge, with a core made of plastic. The first members 30 are more plastic, they can be made of various plastics or natural plastics, preferably they have the form of a sheath in a shell of material enclosing a plastic core. The te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com