Piston-cylinder unit

A technology of piston cylinder and equipment, applied in mechanical equipment, door/window fittings, shock absorbers, etc., can solve problems such as damage, personal injury, loose casing and pressure pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

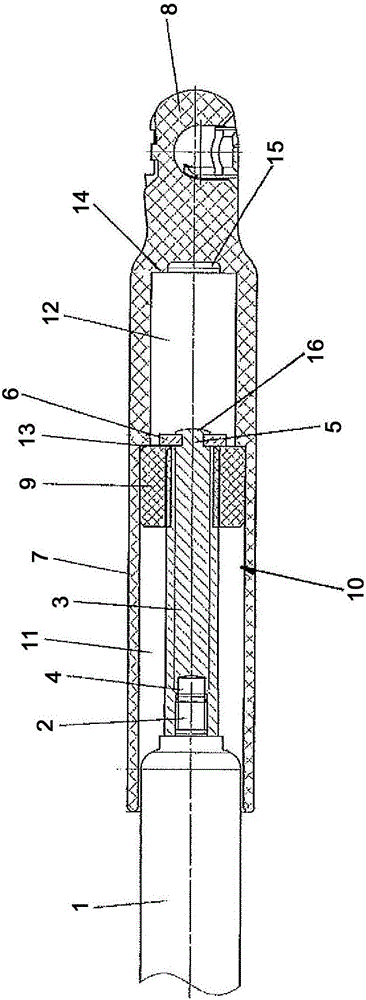

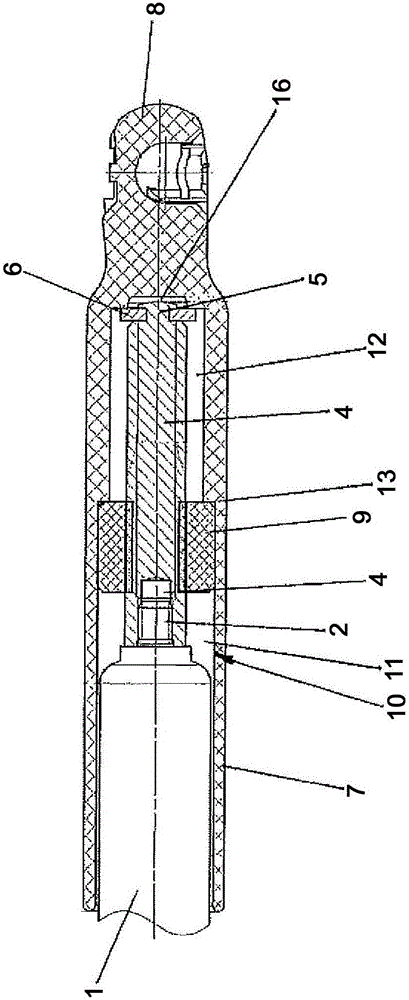

[0025] The illustrated piston-cylinder arrangement is designed to lift, for opening, a tailgate of the vehicle, which is pivotable about a horizontal axis, from a largely downwardly directed closed position into an open position. The piston-cylinder arrangement has a pressure tube 1 of an air spring, at a first end (not shown) of which a piston rod is guided sealingly outward, which carries a first connecting piece at its free end. The first connection part can be a universal joint, which can be fastened to the trunk lid or the body of the vehicle.

[0026] The shown second end of the pressure tube 1 is closed and has an axially protruding threaded journal 2 . The threaded spindle 3 is screwed onto the threaded journal 2 with a threaded bore 4 formed coaxially at one end thereof.

[0027] A nut 9 , for example made of plastic, is screwed onto the threaded spindle 3 .

[0028] The end of the lead screw 3 opposite the threaded hole 4 is designed as a rivet pin 5, the stop wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com