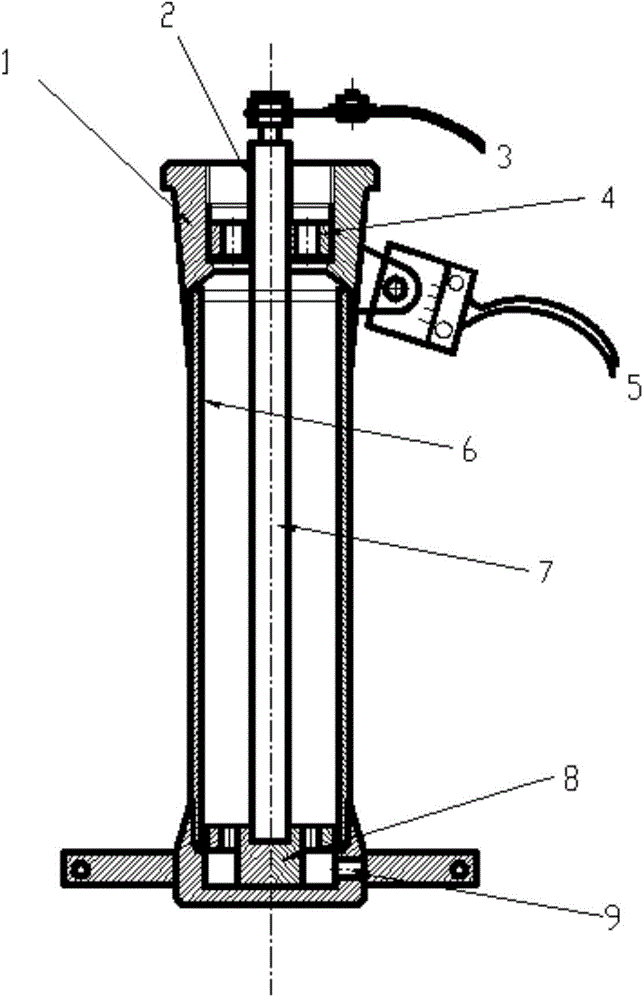

Device and method for hard chrome plating of inner wall of straight cylinder part

A technology of hard chrome plating and parts, which is applied in the field of hard chrome plating on the inner wall of straight parts and hard chrome plating on the inner wall of straight parts. It can solve the problems of slow bath circulation, uneven crystallization of the surface of the chrome plating layer, and excessive local temperature rise. To achieve the effect of speeding up the circulation of the bath solution, solving the unevenness of the coating, and improving the quality of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] 1. Before electroplating, use gasoline to clean the inner and outer surfaces of the electroplated workpiece 1. After degreasing, wash with hot water. After rinsing with tap water, the surface has no water film before putting it into the bath that has been heated and meets the technical requirements to preheat for 1 to 2 minutes. .

[0022] 2. Connect the prepared acid-resistant pump before lowering the tank to circulate the bath liquid. Since the chrome-plating bath liquid is very toxic and will cause great harm to the human body, the power of the acid-resistant pump should not be too large, otherwise it will cause injury due to the too far lift of the bath liquid. And the operator should be selected according to the size of the inner diameter of the straight cylinder. The power of the acid-resistant pump adopted in the present invention is 55kw, the rotating speed is 2900r / h, the lift is 11m, and the suction lift is 3m. The water outlet of the pump is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com