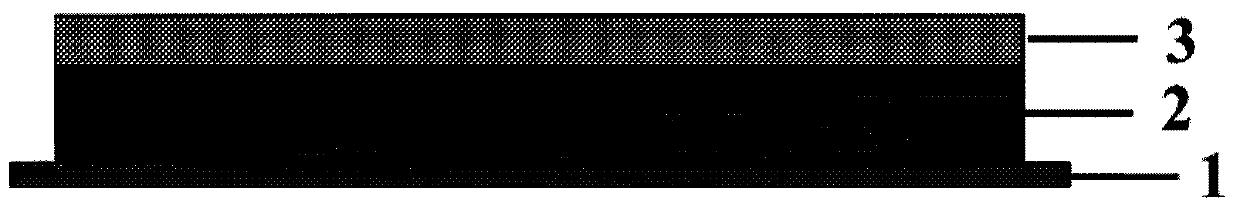

Negative pole piece as well as preparation method and application thereof

A technology of negative pole pieces and ceramic particles, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., to achieve the effect of solving uneven coating and preventing uneven dense accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

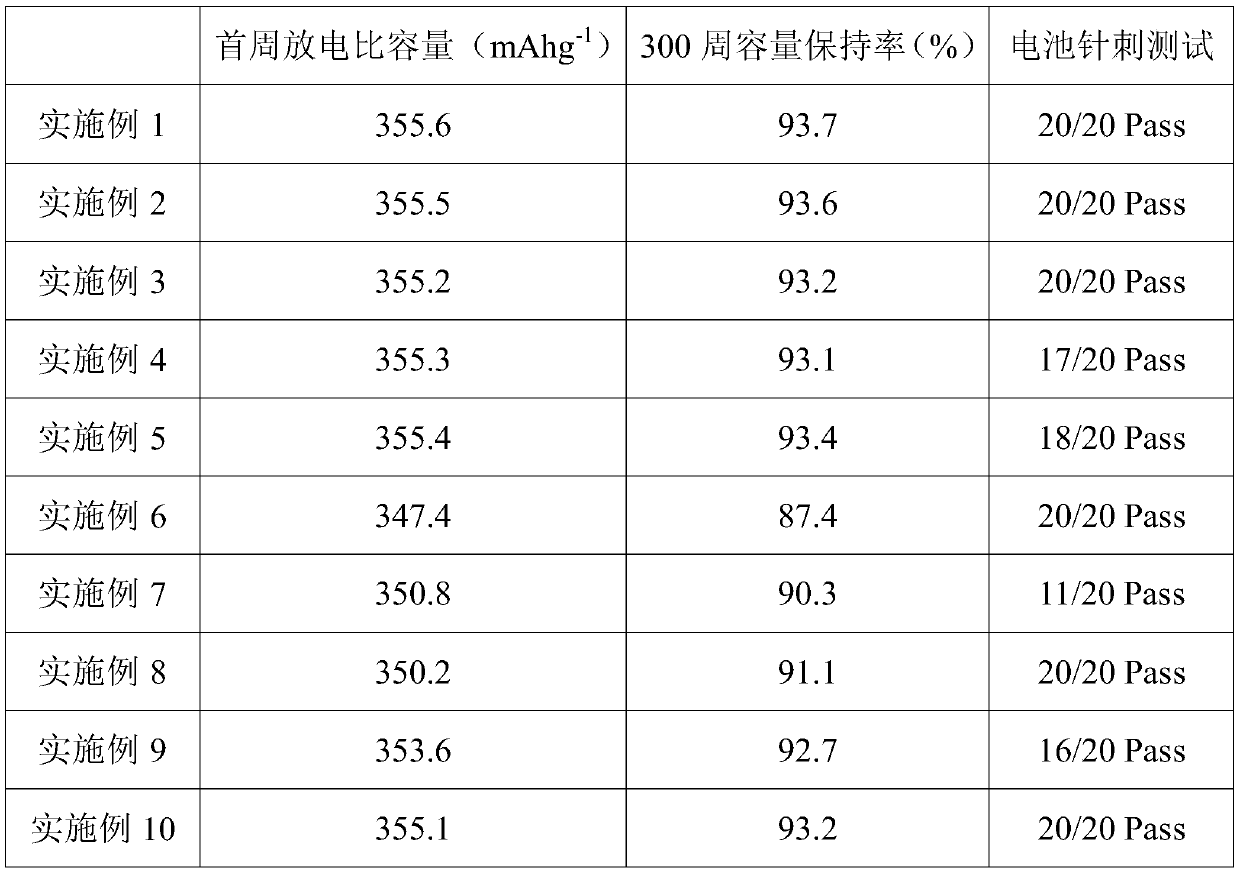

Examples

Embodiment 1

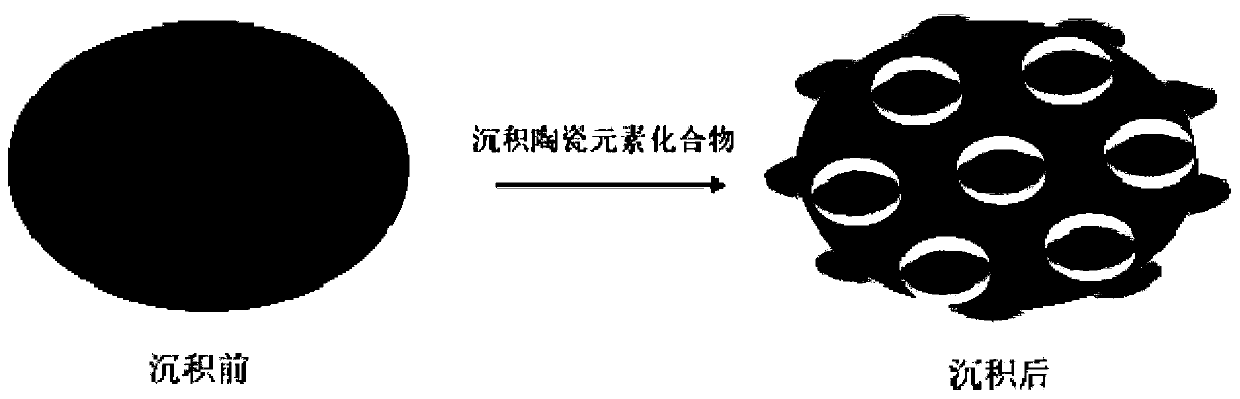

[0089] (1) Preparation of roughened alumina ceramics:

[0090] (a) Aluminum sulfate is mixed with water, stirred at a rotating speed of 200r / min for 5min to obtain an aluminum sulfate solution with a concentration of 0.56mol / mL;

[0091] (b) According to the mass ratio of alumina and the aluminum sulfate is 1:1, the aluminum sulfate solution and the alumina are stirred and mixed at a speed of 800r / min for 30min, filtered to remove water, and then heated in a muffle furnace at 800 Calcined at ℃ for 2 hours to obtain roughened alumina ceramics with an average particle size of 800nm;

[0092] (2) Preparation of ceramic slurry:

[0093] Mixing the roughened alumina ceramics, PVDF and NMP, the mass ratio of the roughened alumina ceramics to the binder PVDF is 97:3, to obtain a ceramic slurry with a solid content of 40%;

[0094] (3) Preparation of negative electrode active material layer:

[0095] Graphite, conductive agent SP, CMC and SBR are prepared into negative electrode ac...

Embodiment 2

[0100] The difference from Example 1 is that the mass ratio of aluminum oxide to aluminum sulfate in step (b) is 0.6:1.

Embodiment 3

[0102] The difference from Example 1 is that the mass ratio of aluminum oxide to aluminum sulfate in step (b) is 1.2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com