Functional sheet

A functional sheet technology, applied in the direction of instruments, chemical instruments and methods, optics, etc., can solve problems such as poor vision, achieve uniform bonding, prevent defects, and suppress cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

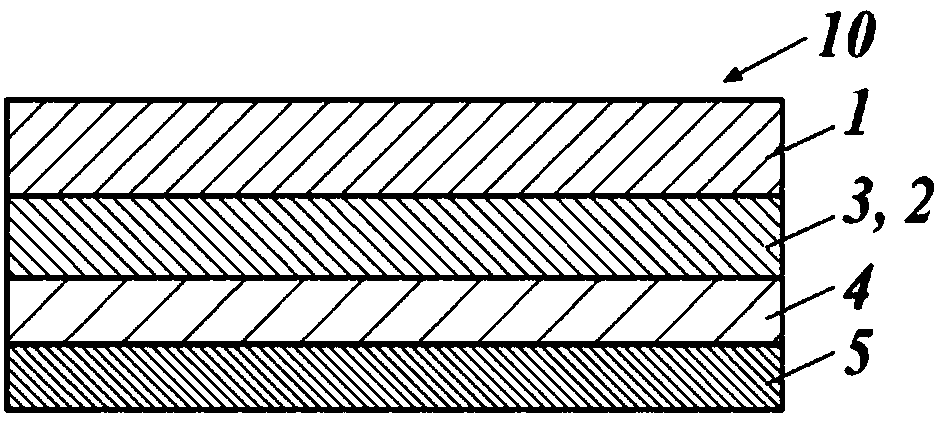

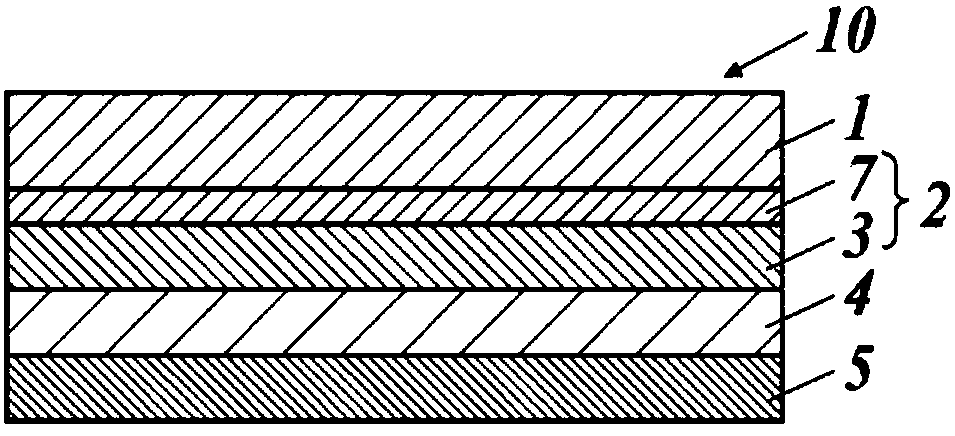

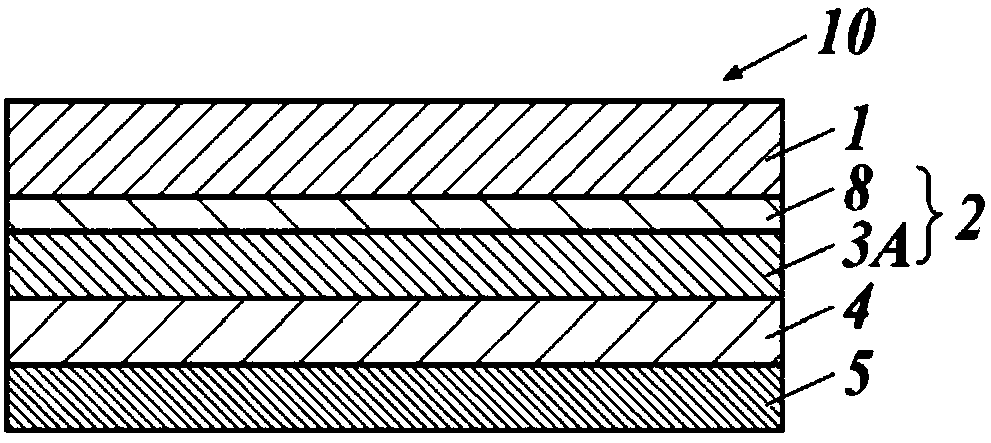

[0222] [Production of functional sheet 101]

[0223] The functional sheet shown in Fig. 1(A) was produced in the following steps.

[0224] Using biaxially stretched polypropylene (Oji F-Tex Co., Ltd. E-201F, thickness 50 μm (in Table 1, PP)) as the first release film, the infrared shielding layer coating composition was prepared according to the following formulation , using a dispensing coater for coating. For coating, the layer thickness was adjusted so that the optical density was 0.12 and the coating was performed. The layer thickness was adjusted so that the dry layer thickness was 3.0 μm, and the coating was performed.

[0225]

[0226]

[0227]

[0228] Next, as an adhesive layer, the coating liquid formulated below was coated on the above-mentioned functional layer. Coating was performed by adjusting the layer thickness so that the dry layer thickness would be 3.0 μm.

[0229]

[0230]

[0231] Finally, use Nakamoto Packs Co., Ltd. NS SEPARATOR XA (セパレ...

Embodiment 2

[0293] [Production of functional sheet 201]

[0294] In preparation of the functional sheet 102, the functional sheet 201 of the comparative example was produced in the same manner except that the second release film was not laminated.

[0295] [Production of functional sheet 202]

[0296] In the production of the functional sheet 102, the aging temperature was adjusted, and the peeling force of the first release film and the second release film were both adjusted to 70mN / 50mm. In addition, the functional sheet of the comparative example was produced in the same manner. 202.

[0297] [Production of functional sheet 203]

[0298] In the production of the functional sheet 102, the aging temperature was adjusted, and the peeling force of the first release film and the second release film were both adjusted to 2400mN / 50mm. In addition, the functional sheet of the comparative example was produced in the same manner. 203.

[0299] [Production of functional sheet 204]

[0300] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com