Novel composite twistless spinning machine

A composite spinning and spunbonding technology, which is applied in the direction of textiles and papermaking, can solve the problems of high processing cost, unstable spinning quality, poor penetration, etc., to solve low production efficiency, unstable spinning quality, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

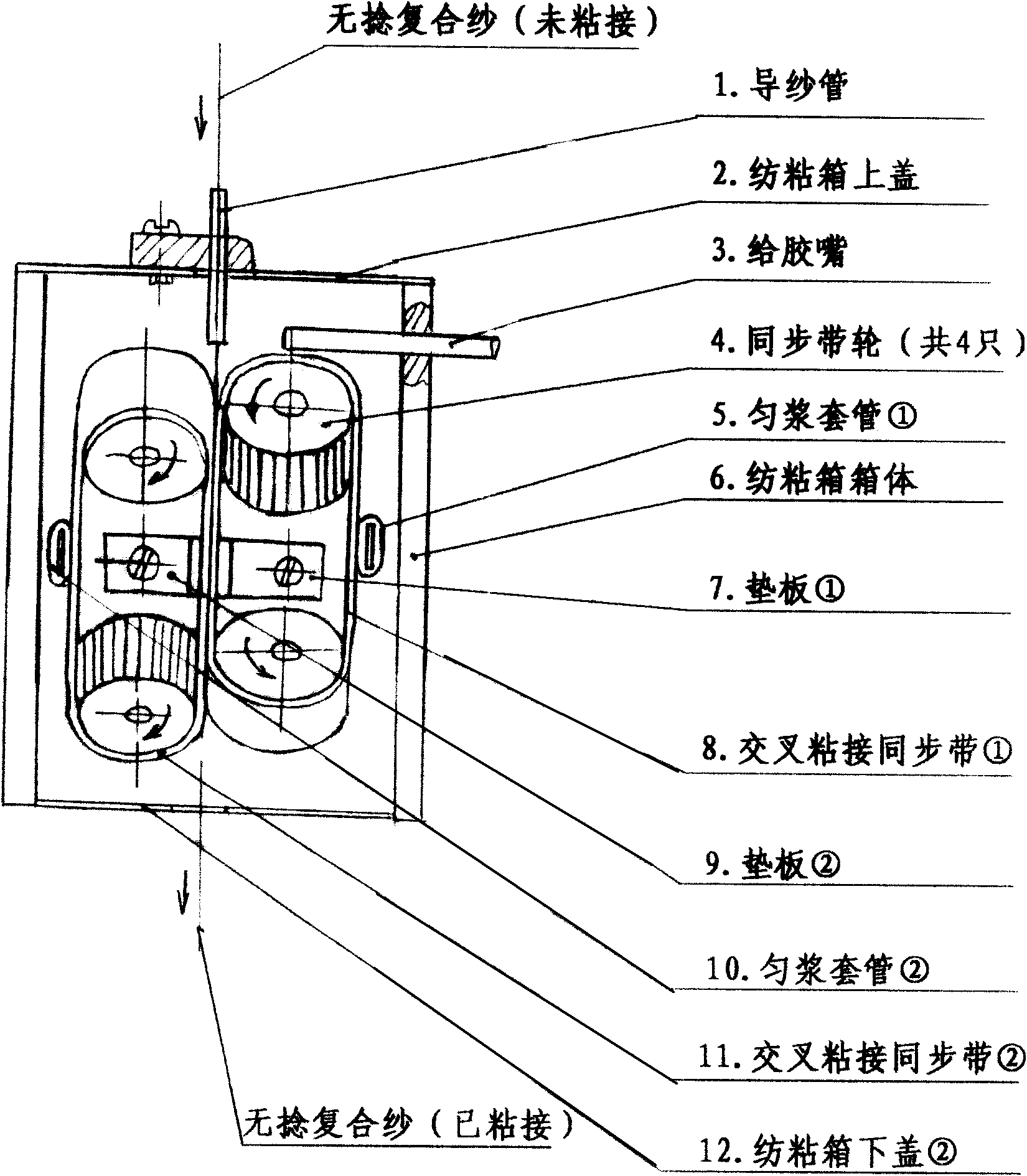

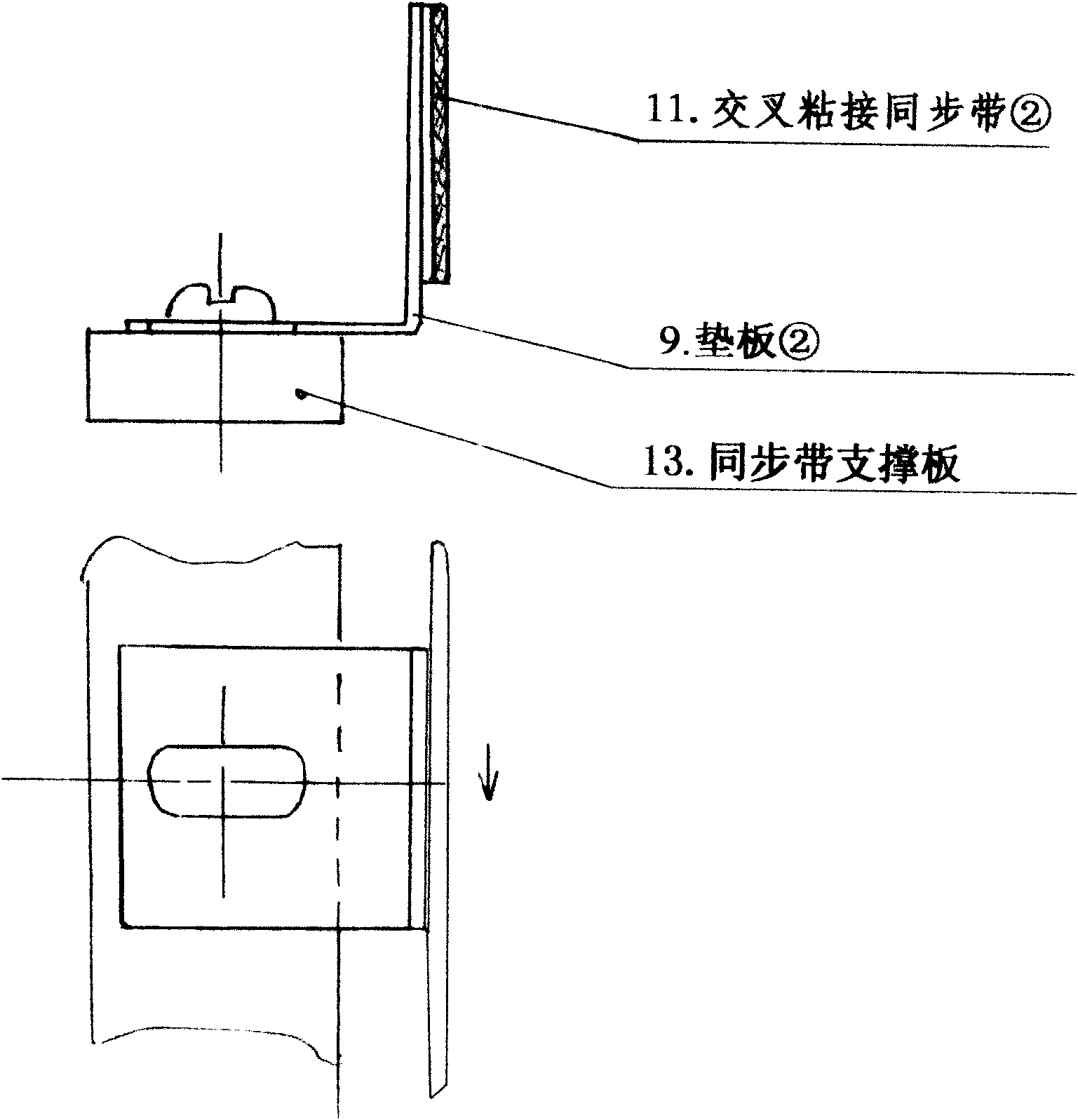

[0022] exist Figure 1 , The untwisted composite yarn (unbonded) passes through 1. The yarn guide tube enters the working area clamped by two cross-bonded synchronous belts. 3. Apply the adhesive to the glue nozzle according to a certain amount, and evenly give it to the surface of 8. Cross-bonded synchronous belt ①. After the interaction of 8. cross-bonded timing belt ① and 11. cross-bonded timing belt ②, under the auxiliary homogenization of 5. homogenizing sleeve ① and 10. homogenizing sleeve ②, the adhesive is uniform Apply on the surface of 8. Cross-bonded timing belt ① and 11. Cross-bonded timing belt ②. The non-twisted composite yarn (not bonded) is evenly coated on the non-twisted composite yarn under the false twist rubbing of two cross-bonded synchronous belts and the auxiliary extrusion of 7. backing plate ① and 9. backing plate ② yarn (unbonded) surface and penetrates the yarn interior.

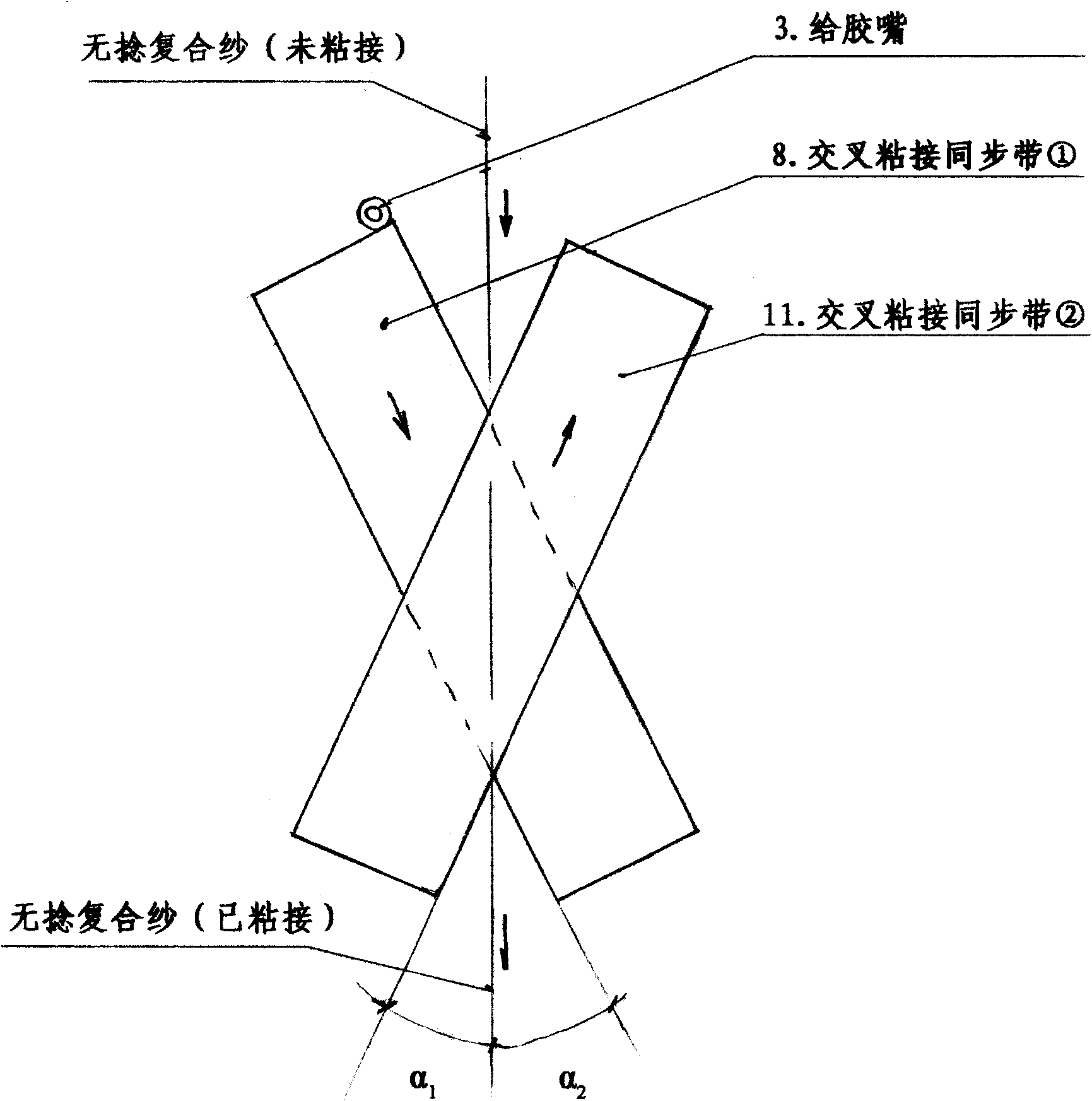

[0023] exist Figure 2 , 3. The position of the glue nozzle is given from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com