Multi-shaft fluctuating rotation transmitting device and power generation device used for multi-shaft fluctuating rotation transmitting device

A torque-transmitting, single-axis technology, applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the problems of low working efficiency of generators, inability to generate electric energy, and reverse motion, etc., so as to facilitate implementation and promotion Use, low cost, and stable output rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

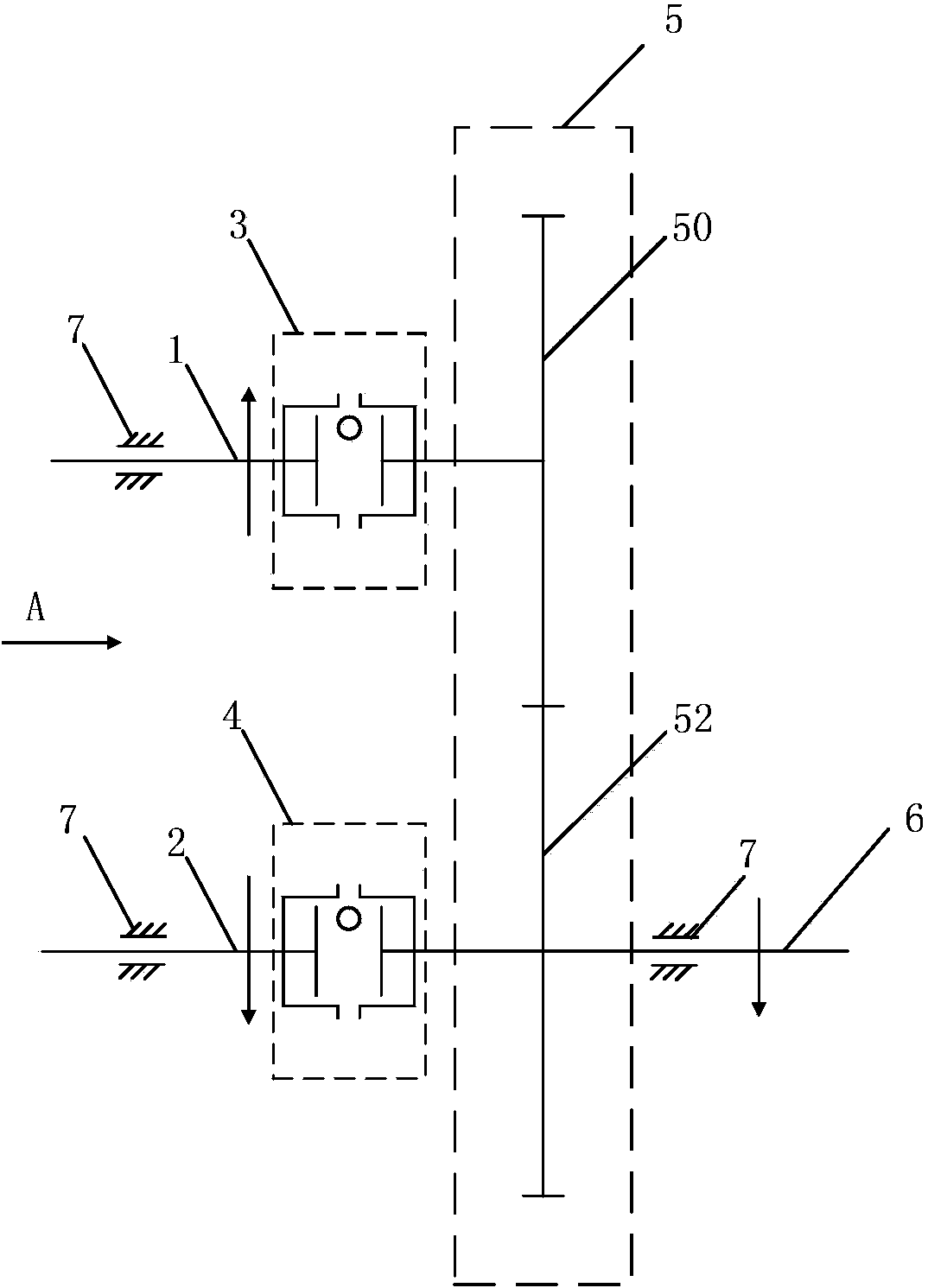

[0014] Specific implementation mode one: combine figure 1 This embodiment will be described. This embodiment includes a first drive shaft 1 , a first overrunning clutch 3 , a first gear 50 , a second drive shaft 2 , a second overrunning clutch 4 , a second gear 52 , and an output shaft 6 . The first gear 50 is connected with the first drive shaft 1 through the first overrunning clutch 3 , the second gear 52 is connected with the second drive shaft 2 through the second overrunning clutch 4 , and the first gear 50 is meshed with the second gear 52 . The rotation transmission directions of the two overrunning clutches are opposite, and the respective transmission directions are respectively shown by the arrows in the figure.

[0015] The working principle of this embodiment is:

[0016] When the first drive shaft 1 reaches the rotational speed of the first gear 50 along the direction shown in the figure (counterclockwise when viewed from direction A), the first overrunning clutc...

specific Embodiment approach 2

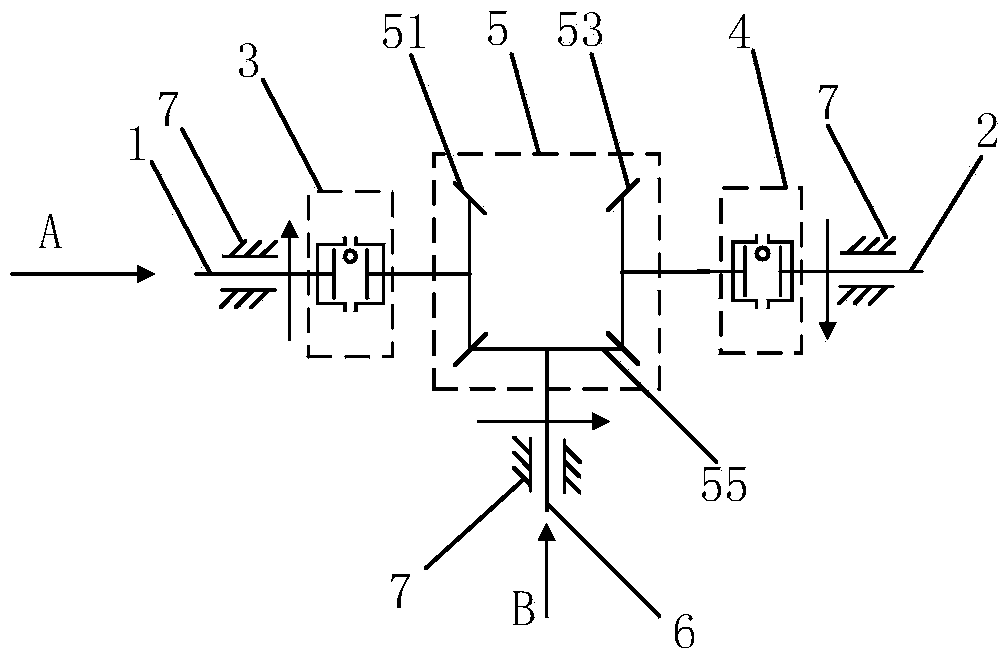

[0019] Specific implementation mode two: combination figure 2 Describe this embodiment, this embodiment includes the first drive shaft 1, the first overrunning clutch 3, the first bevel gear 51, the second drive shaft 2, the second overrunning clutch 4, the second bevel gear 53, and the third bevel gear 55 , Output shaft 6. The first bevel gear 51 is connected with the first drive shaft 1 through the first overrunning clutch 3, and the second bevel gear 53 is connected with the second drive shaft 2 through the second overrunning clutch 4. The first bevel gear 51 and the second bevel gear 53 are respectively It meshes with the third bevel gear 55 . The rotation transmission directions of the two overrunning clutches (3, 4) are opposite, and the respective transmission directions are respectively shown by arrows among the figures. Wherein the overrunning clutch can be replaced by the ratchet that plays the same direction of action.

[0020] The working principle of this embo...

specific Embodiment approach 3

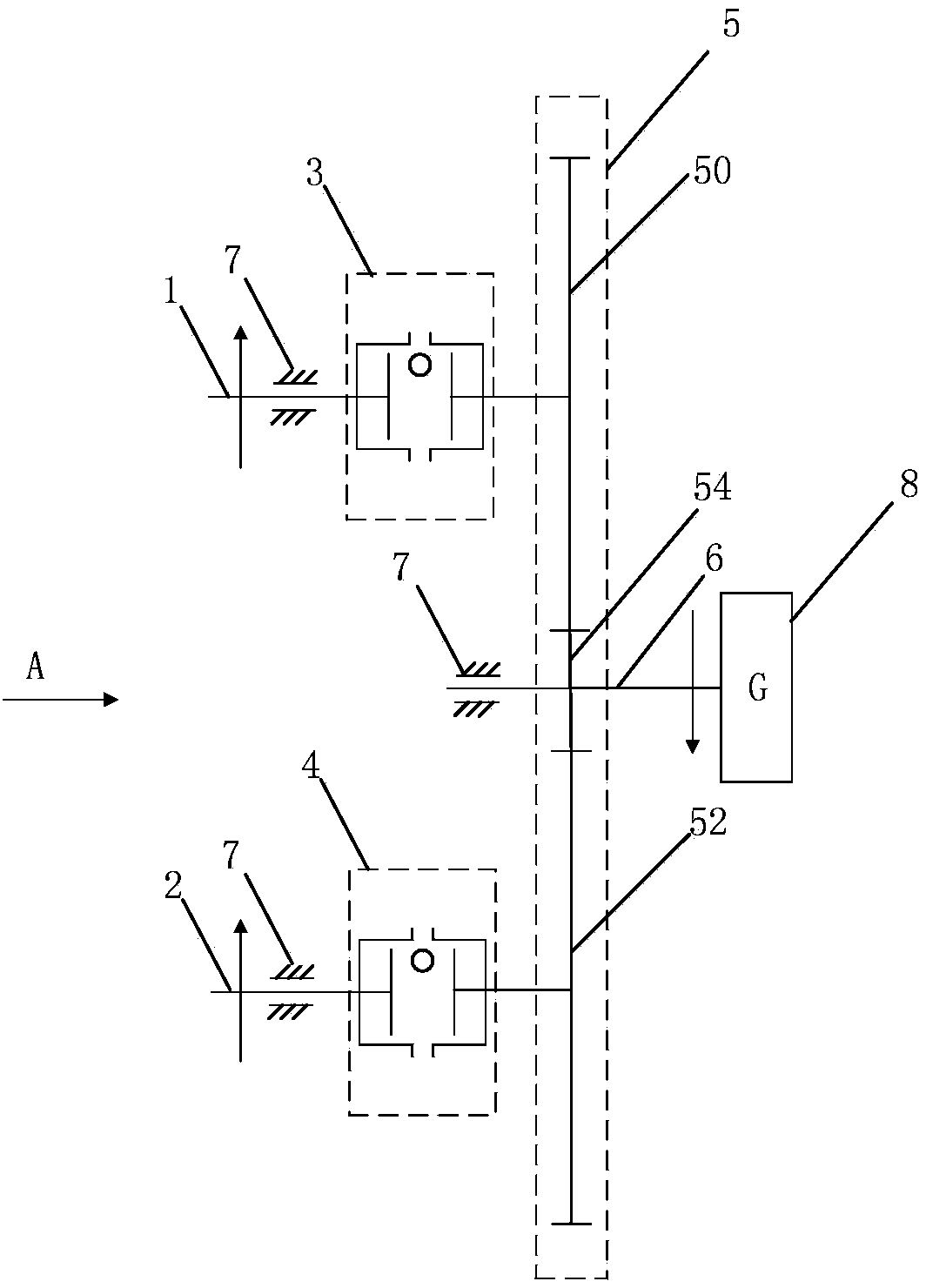

[0024] Specific implementation mode three: combination image 3 Describe this embodiment, this embodiment includes the first drive shaft 1, the first overrunning clutch 3, the first gear 50, the second drive shaft 2, the second overrunning clutch 4, the second gear 52, the third gear 54, the output shaft 6. Generator 5. The first gear 50 is connected with the first drive shaft 1 through the first overrunning clutch 3, the second gear 52 is connected with the second drive shaft 2 through the second overrunning clutch 4, and the first gear 50 and the second gear 52 are respectively connected with the third gear The 54 phases are meshed, and the output shaft is connected with the generator to drive the generator to generate electricity. The rotation transmission direction of the two overrunning clutches is the same, and the transmission direction is shown by the arrow in the figure. Wherein the overrunning clutch can be replaced by the ratchet that plays the same direction of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com