Dog clutch for vehicle transmission

A technology for automotive transmissions and hubs, applied to clutches, elements with teeth, mechanically driven clutches, etc., can solve problems such as high noise generation, component load, cogging engagement and low shift comfort, and achieve high friction torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

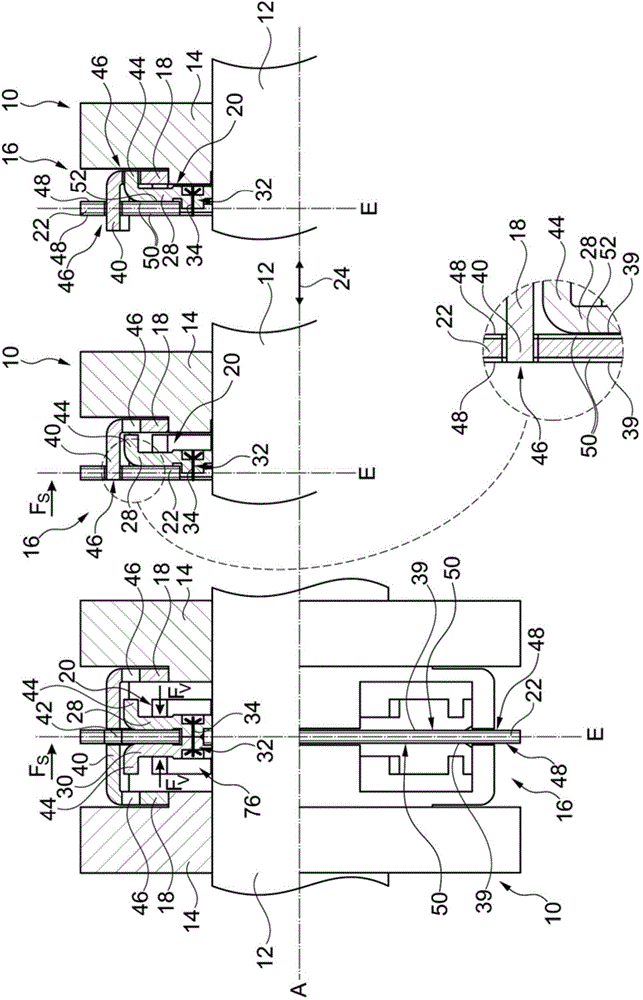

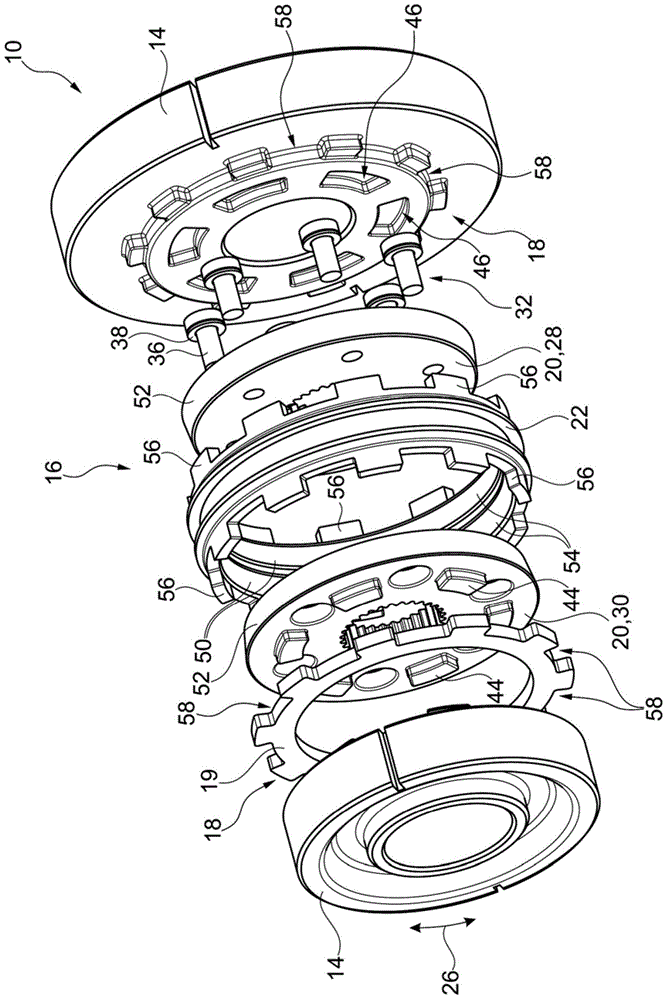

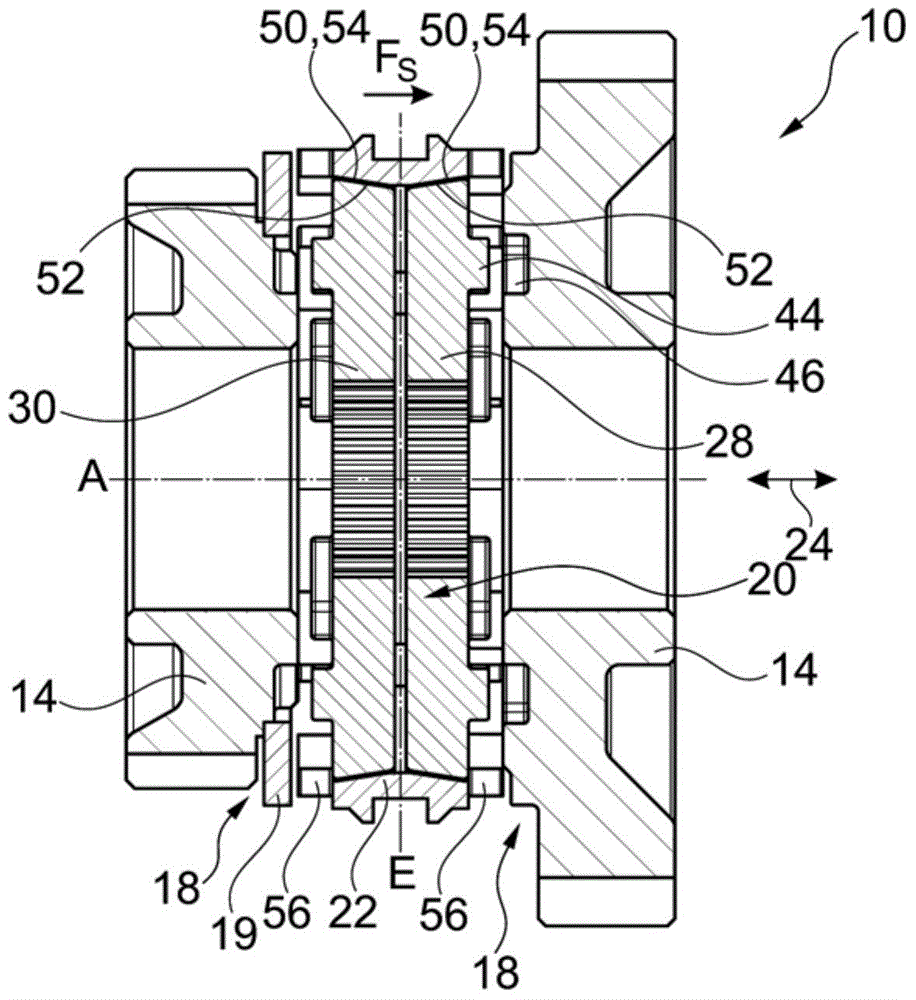

[0029] Figure 1 to Figure 9 It relates to a vehicle transmission 10, in particular a dual-clutch transmission or an automatic transmission, having: a transmission shaft 12 rotatable about a transmission axis A, two rotatable on the transmission shaft 12 and (except limited by production conditions and for driven Outside the desired bearing clearance for the safety function) the driven wheel 14 is supported axially immovably, and the cogging engagement 16. In this case, the driven wheels 14 of the motor vehicle transmission 10 are each fixedly connected, in particular constructed in one piece or welded, to the coupling body 18 of the dog joint 16 . according to Figure 2 to Figure 4 On the (left) side of the dog engagement 16 facing the smaller output wheel 14 , there is provided a separate clutch output plate 19 belonging to the coupling body 18 , which is firmly pressed in with the output wheel 14 .

[0030] The dog joint 16 for the vehicle transmission 10 comprises: two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com