Shaft lock device

A shaft locking and central shaft technology, which is applied in pivot connection, multi-purpose hand tools, faulty computer hardware detection, etc., can solve the problem of inability to determine the location of friction torque, increase of parts with friction torque, and inability to ensure friction torque and other problems, to achieve the effect of simple structure, stable friction torque and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

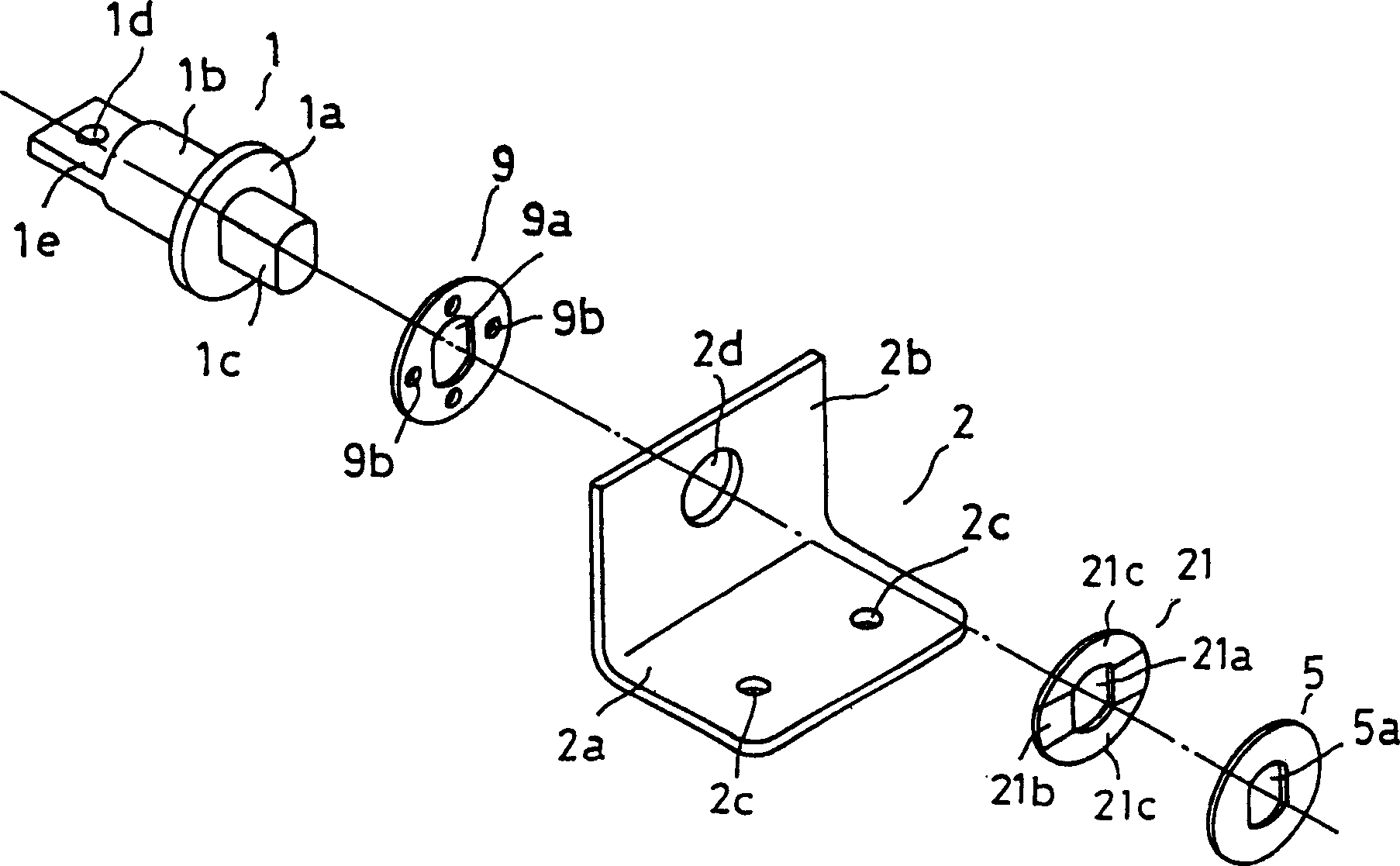

[0023] figure 1 Shown is Embodiment 1 of the present invention, which is composed of a central shaft 1, a friction plate 9, a bracket 2 as an interactive part, an elastic pressing part 21, a stop plate 5 and the like. A friction plate 9 , a bracket 2 , an elastic pressing member 21 , a stopper plate 5 and the like are mounted on the center shaft 1 . An insertion portion 1a is arranged on the central axis 1, and both sides of the insertion portion 1a start to the installation shaft portion 1b and to the connection shaft portion 1c, which extend coaxially, and the installation shaft portion 1b is installed on the display panel as a connecting part, (shown Omit) For ease of installation, a fixed hole 1d is provided at the end of the thin plate-shaped mounting piece 1e, and the connecting shaft portion 1c is where the friction plate 9, the bracket 2, the elastic pressure member 21, the stop plate 5, etc. are installed. After planing, the connecting shaft portion 1c has a non-cir...

Embodiment 2

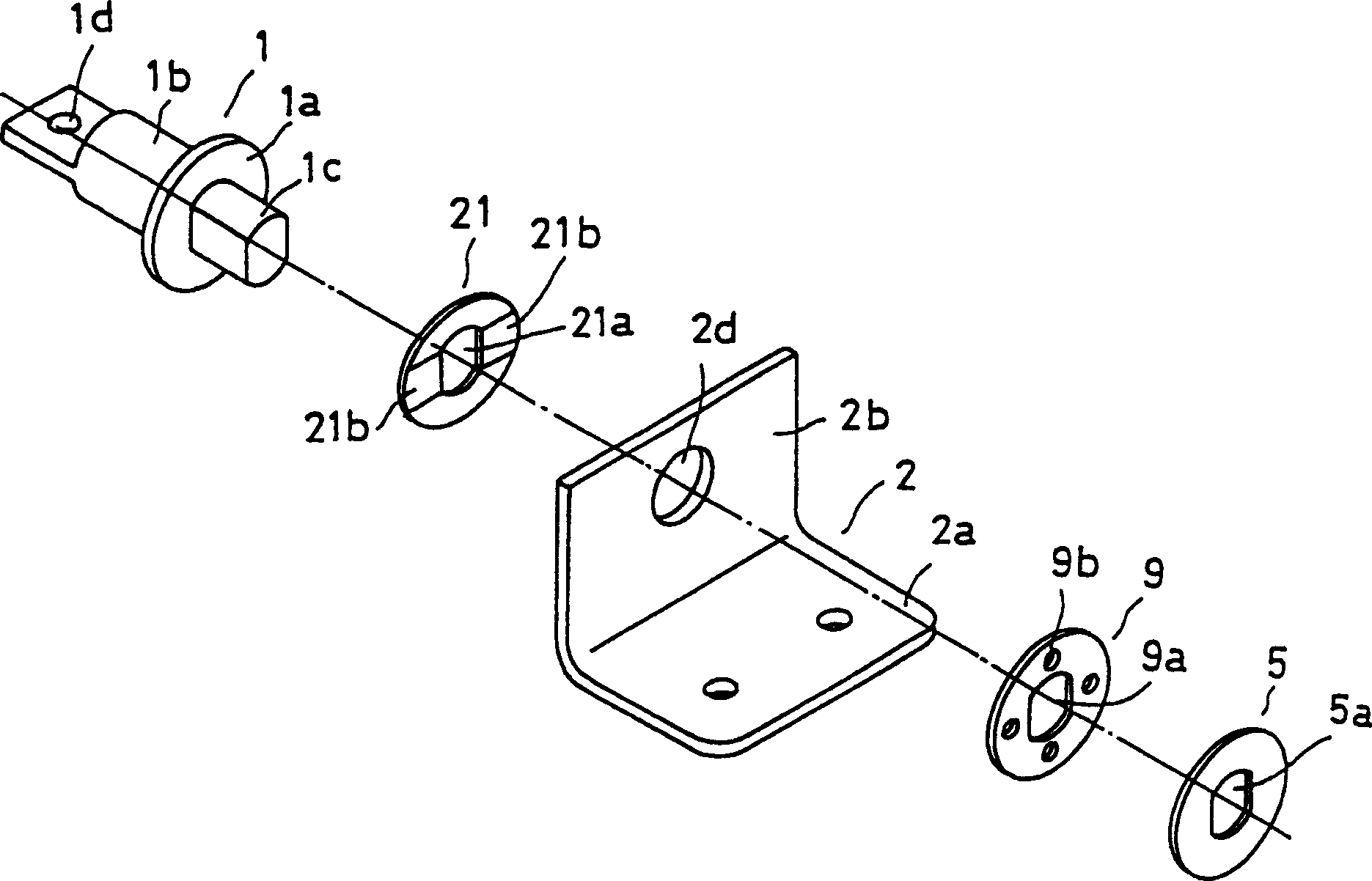

[0027] image 3 Example 2 is shown, and this example is different from the elastic pressing member in the above-mentioned example 1 in that two U-shaped springs 21 are used. These two U-shaped springs 21 overlap and are arranged between the bracket 2 and the stop plate 5. In this case, the U-shaped spring 21 on the side of the bracket 2, the bottom surface of its planar portion 21b and the bracket In this case, the protrusion 21c of the U-shaped spring 21 is in contact with the protrusion 21c of the U-shaped spring 21 on the other side along the plane portion 21b, (that is, 2 Sheet U-shaped springs 21 are staggered and overlapped). Then, the end portion of the connecting shaft portion 1c penetrating through the stopper 5 is fastened, and the two U-shaped springs 21 are alternately overlapped to apply pressure to the shaft supporting portion 2b of the bracket 2 . In this case, the two U-shaped springs 21 are arranged along the central axis, and the plurality of U-shaped sprin...

Embodiment 3

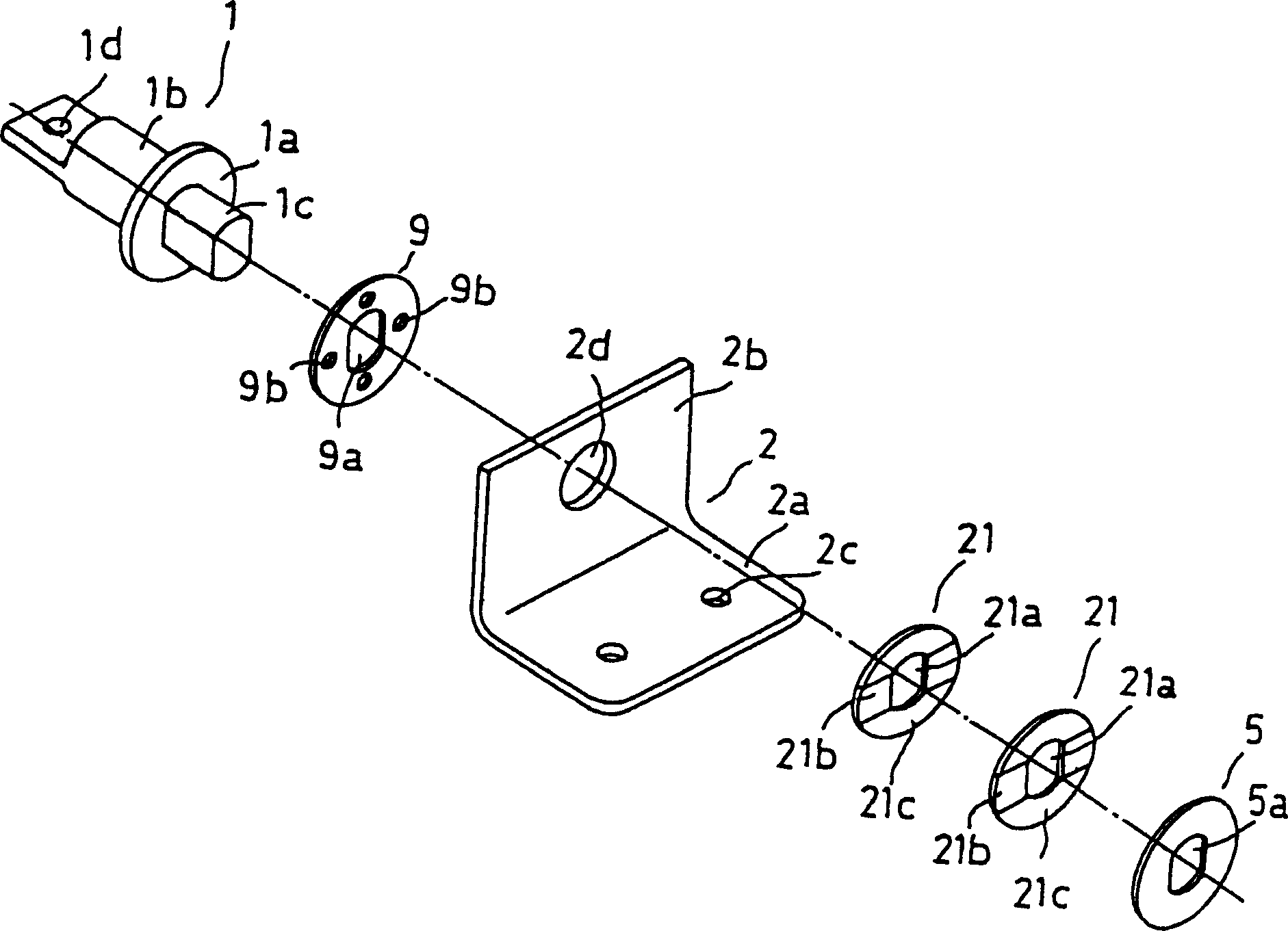

[0030] Figure 4 Example 3 is shown. In this example, the friction plate 9 in Example 1 is omitted, that is, for the bracket 2, the U-shaped spring 21, and the stopper 5, the connecting shaft portion 1c of the central shaft 1 is used to pass through it. The end is fastened, the insertion part 1a of the central shaft 1, the shaft support part 2b of the bracket 2, the U-shaped spring 21 and the stopper 5 overlap, and the friction torque generated by the direct pressure of the U-shaped spring 21 Under the action, the central axis 1 and the bracket 2 can maintain the mutual angle. In this state, friction occurs between the insertion portion 1a of the central shaft 1 and the shaft support portion 2b of the bracket 2, and the smaller the friction force, the longer the service life of these components. This structure has the advantages of easy installation and the like while reducing its weight due to fewer components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com