Rotational torque, radial force and axial force comprehensive loading test method and device

A loading test device and technology of loading device, which are applied in the field of comprehensive loading of radial force and axial force and rotational torque, can solve the problems of complex structure and high sealing requirements, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

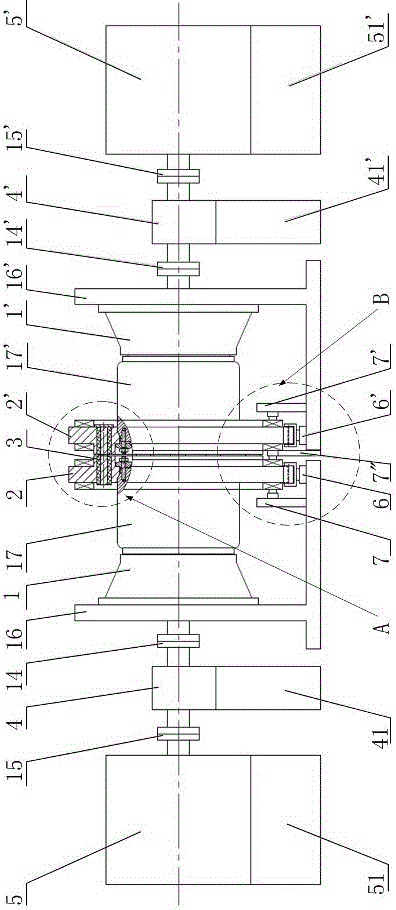

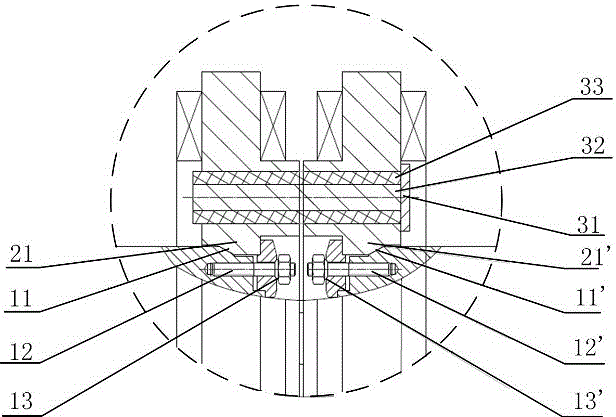

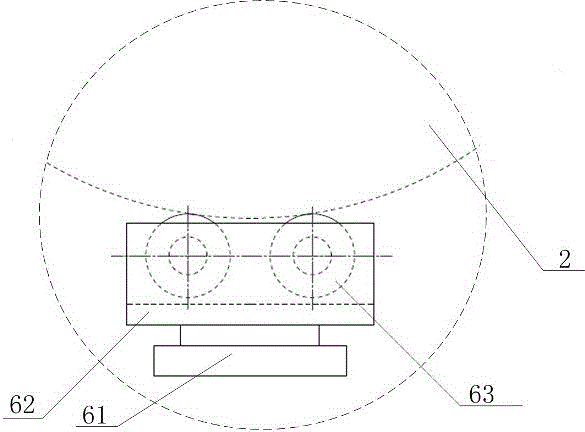

[0030] The rotational torque, radial force and axial force comprehensive loading test method of a kind of transmission system of the present embodiment, such as Figure 1~Figure 4 shown, including the following steps:

[0031] a. Install a pair of transmission system I1 and transmission system II1' back-to-back, between the transmission system I1 and the back-to-back connection flange I2, the conical surface 11 of the hub of the transmission system I1 matches the conical surface 21 of the back-to-back connection flange I2, and The press-fit bolt I12 screwed into the hub 17 of the transmission system I1 presses the pressure block I13 used to limit its axial displacement and is fixedly connected; between the transmission system II1' and the back-to-back connecting flange II2' passes through the hub of the transmission system II1' The conical surface 11' matches the conical surface 21' of the back-to-back connection flange II2', and presses the pressure block II13 for limiting it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com