Center friction wheel driven-type special elevator bearing simulation tester

A simulation test and friction wheel technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of complex loading and driving systems, long test data and result acquisition cycle, poor contrast, etc., to achieve simple structure, strong contrast of results, and increased contrast Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

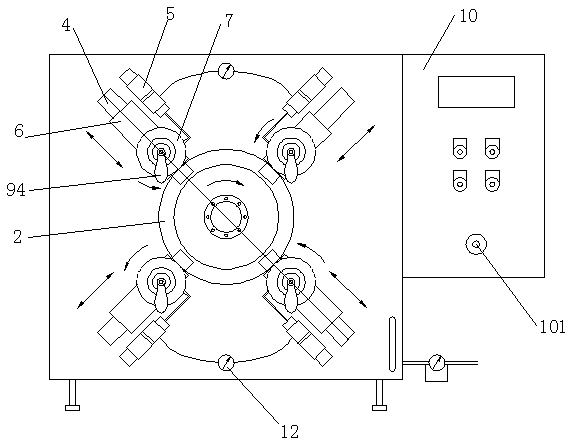

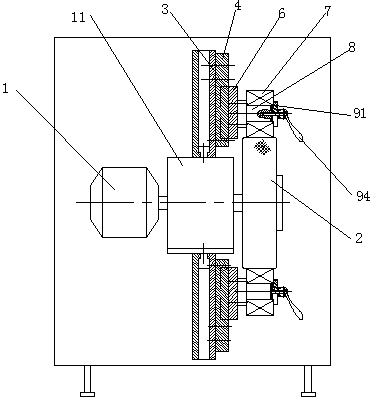

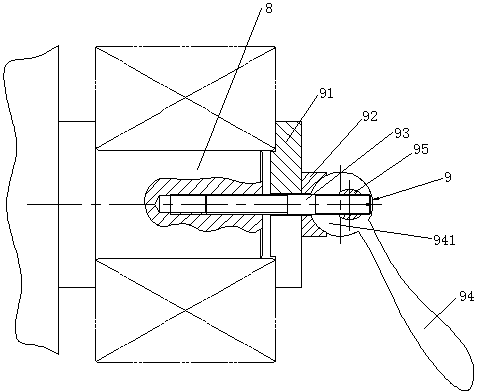

[0020] A special bearing simulation test machine driven by a central friction wheel for elevators, which is characterized in that: a friction wheel is set at the center of the panel of the test machine to drive the running of the bearing, and several sets of test bearings are arranged symmetrically in a planetary manner on the outer periphery of the test machine, adjustable The cylinder completely simulates the actual industrial and mining bearing state of the bearing. The air pressure is loaded on the test bearing and pressed against the outer wall of the friction wheel. The friction wheel drives each test bearing through the test parameters set in advance by the programmable controller to simulate the lifting, falling and stopping of the elevator. Do timing steering switching, acceleration and deceleration rotation and intermittent pause cycle running. At the same time, the temperature rise of the bearing is measured by connecting the temperature sensor to the test bearing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com