A Method for Accurately Measuring the Disturbance Range of Gas-Phase Fracturing

An accurate measurement and range technology, applied in the field of accurate determination of gas phase fracturing disturbance range, can solve problems such as increased costs, hidden dangers of safe production, and inaccurate test disturbance range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention provides a method for accurately measuring the disturbance range of gas phase fracturing, the method has the following steps:

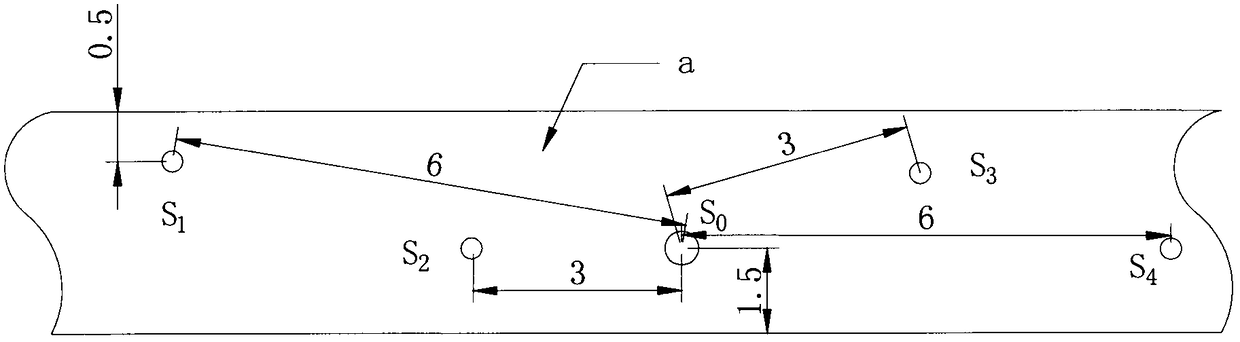

[0025] (1) On the roadway coal wall in the area where gas-phase fracturing is required, four disturbance recording holes S are arranged around the fracturing holes, which are upwardly inclined by 2 degrees along the coal seam direction 1 , S 2 , S 3 , S 4 , hole S1 is a hole opened 0.5m away from the upper part of the roadside, 6m away from the left side of the fracturing hole position, hole S 2 The hole height is 1.5m, located 3m to the left of the fracturing hole, hole S 3 It is a hole opened 0.5m away from the upper part of the side of the roadway and 3m away from the right side of the fracturing hole position. Hole S 4 The hole height is 1.5m, located 6m to the right of the fracturing hole;

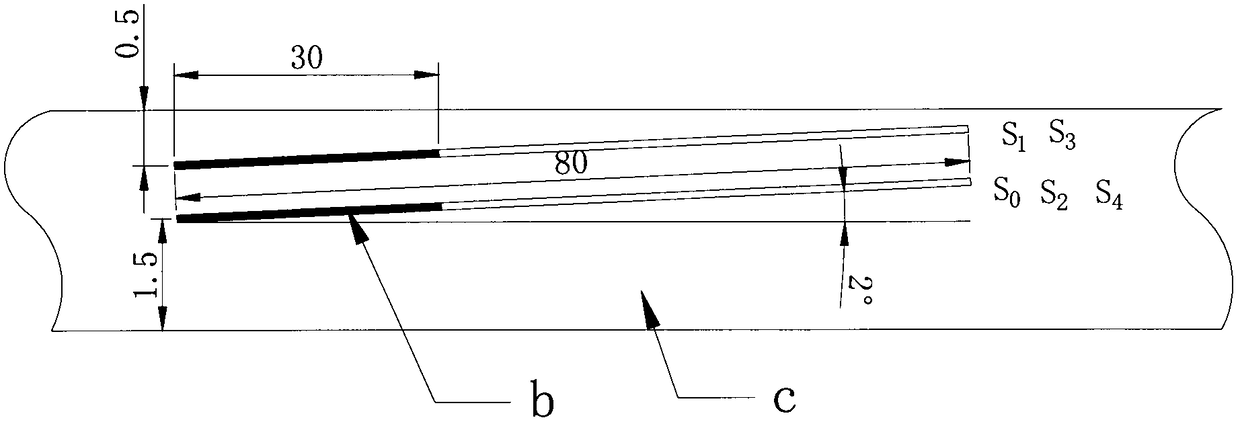

[0026] (2), use 4 branch pipes to go down to 40m in the disturbance recording hole and seal the hole, the hole sealing depth is 30m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com