A method for measuring trace gas

A trace gas and gas technology, which is applied in indirect mass flow meters, mass flow measurement devices, etc., can solve the problems of corrosion, complicated operation, and low gas volume in the detection gas, and achieve the effect of low cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

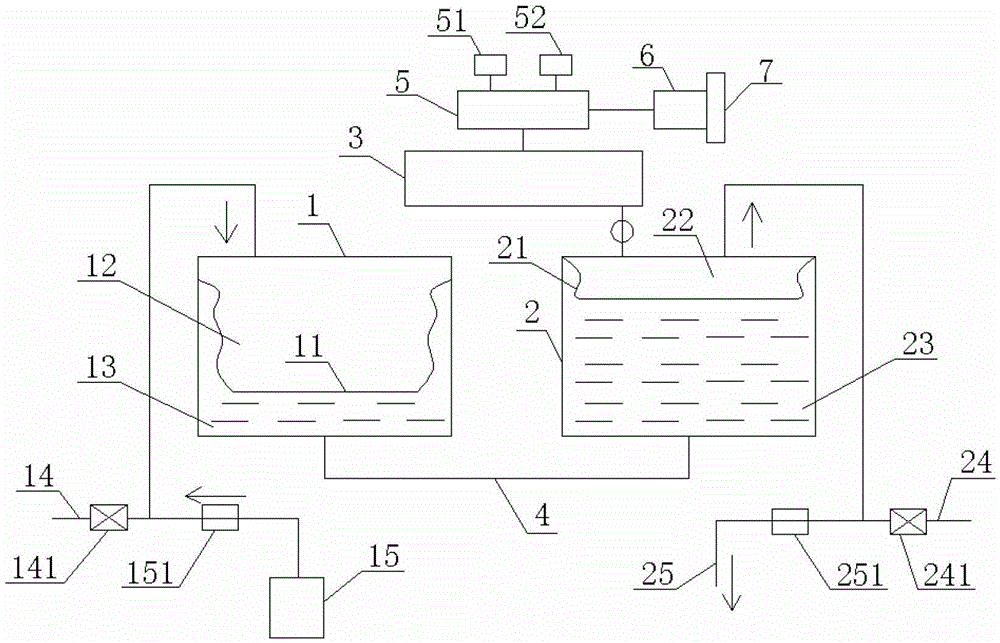

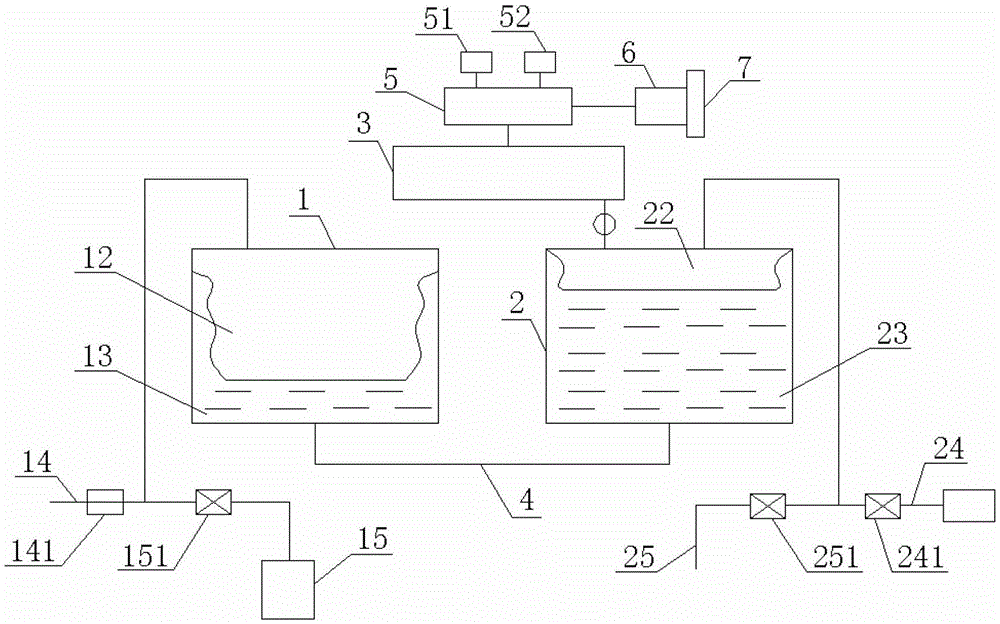

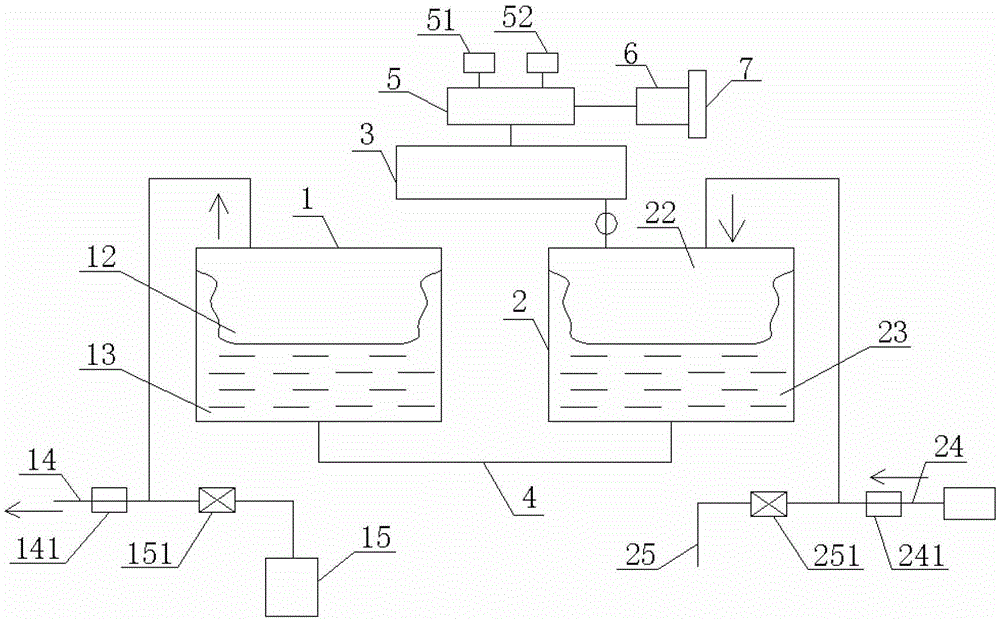

[0031] like figure 1 The shown embodiment 1 is a trace gas flowmeter, which mainly includes a fixed cavity 1, a weighing cavity 2 and a load cell 3, and the trace gas to be measured is filled into the weighing cavity 2, because the weighing cavity The unique design of the chamber 2 enables the volume change of the gas in it to be reflected in the weight change of the liquid, and then the flow rate of the trace gas can be deduced by measuring the weight value change of the weighing chamber 2 by the load cell 3 . specific:

[0032] The fixed cavity 1 is divided into a first air storage chamber 12 and a first liquid storage chamber 13 by a first elastic diaphragm 11 that can freely expand and contract, and the first air storage chamber 12 and the first liquid storage chamber 13 are not communicated with each other. The first air storage chamber 12 communicates with an exhaust pipe 14 for exhausting air and an air pump 15 for inflating the first air storage chamber 12 respectivel...

specific Embodiment

[0035] like Figure 1-Figure 3 As shown, it is a specific embodiment of the trace gas measuring method of the present invention, which mainly includes the following steps:

[0036] step 1( figure 1), preparation—open the second switching valve 151 and the third switching valve 251, close the first switching valve 141 and the fourth switching valve 241, start the air pump 15 to inflate the first air storage chamber 12, and the first air storage chamber 12 expands Press the liquid in the first liquid storage chamber 13 to flow into the second liquid storage chamber 23 from the connecting pipe 4, and force the second gas storage chamber 22 to shrink, and the gas in the second gas storage chamber 22 is discharged from the collection pipe 25 to the second When the liquid level of the liquid storage chamber 23 is higher than that of the first liquid storage chamber 13, the air pump 15 is turned off, and it is better to drain or substantially discharge the gas in the second gas stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com