Directional turning gear

A directional disc and steering wheel technology, which is used in the testing of measuring devices, instruments, and mechanical parts, etc., can solve the problems of non-standard and unified measuring points, prolonged engineering construction period, high labor intensity, etc., to achieve flexible and stable devices, and extended operation. Longevity, the effect of avoiding repeated exploration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

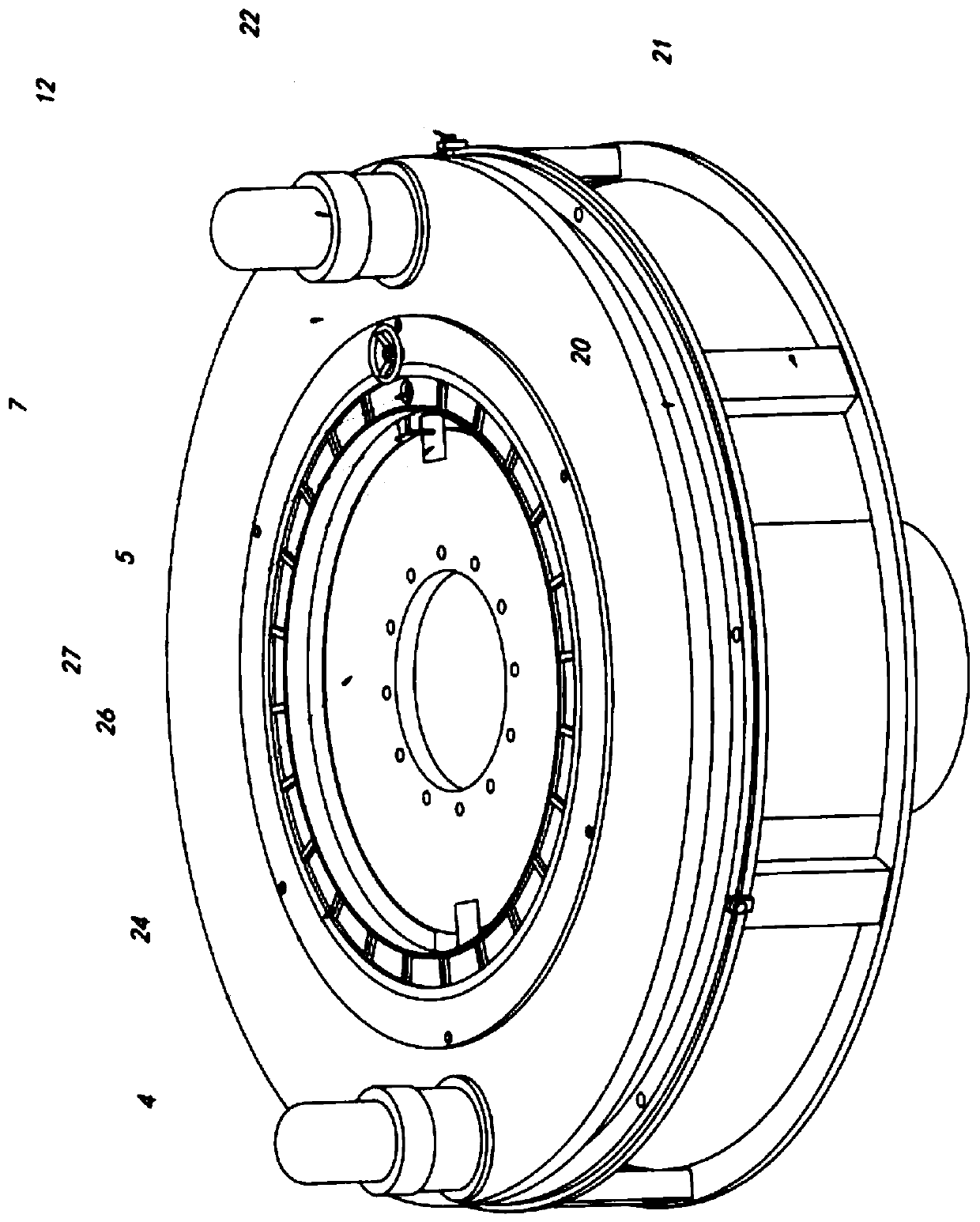

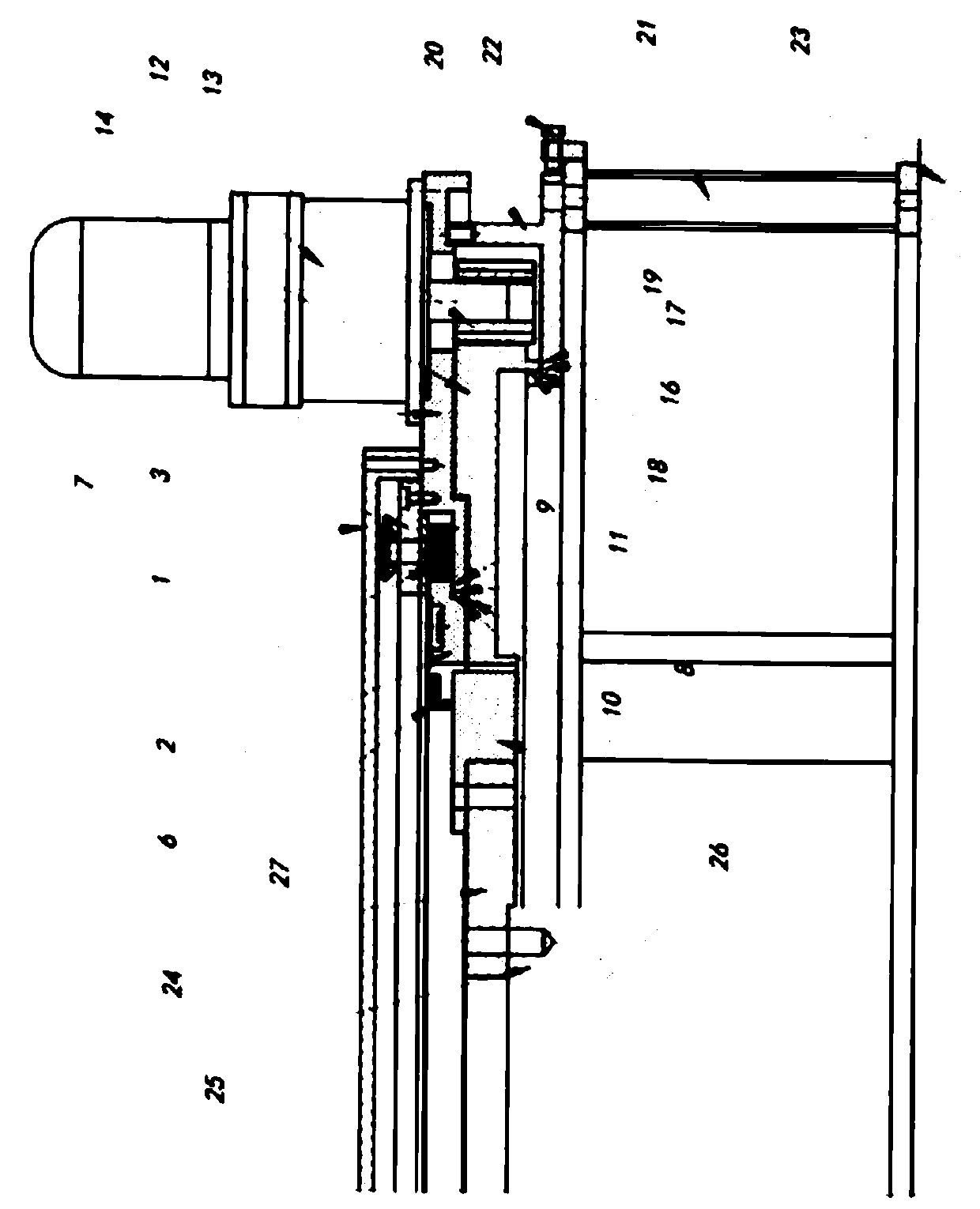

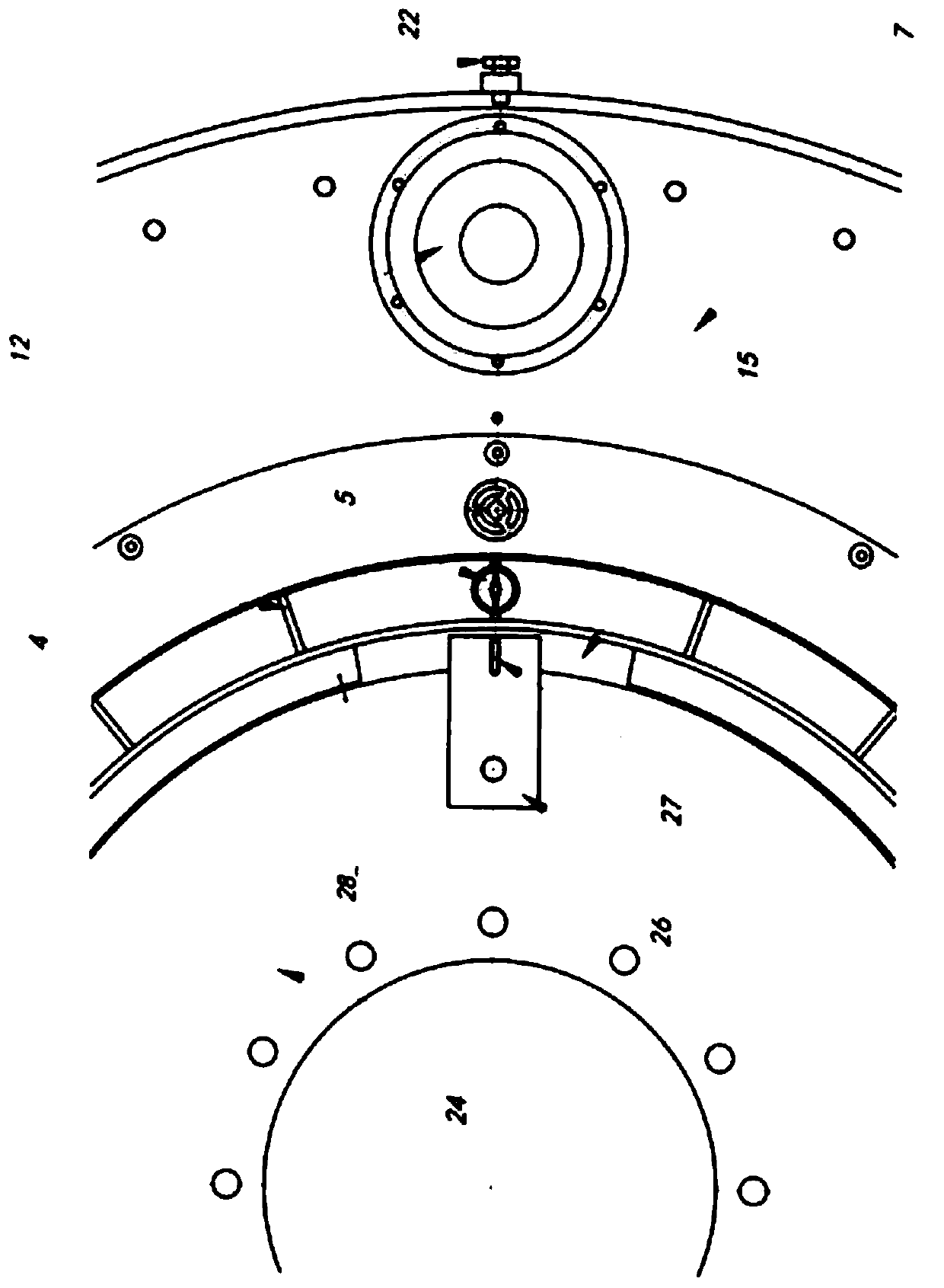

[0022] With reference to the accompanying drawings, the specific embodiments of the present invention, such as the shape and structure of each component involved, the mutual position and connection relationship between each part, the function and working principle of each part, etc. detailed description.

[0023] The working principle of the directional turning device of the present invention is: when the orientation is determined and the power is turned on, the reducer 12 with rotational power assembled in a 180° symmetrical position forms a force couple, and the rotational power can be generated by the motor. The number of reducers can be determined according to the size of the load. The output shaft of the reducer drives the pinion 13 to rotate, and the similarly symmetrically distributed pinions drive the large gear 14 that meshes with it to rotate. Since the large gear is subjected to a pair of balanced tangential forces, the large gear 14 drives the coupling 24 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com