Efficient earth taker

A soil borrower and high-efficiency technology, which is applied in the field of geological exploration equipment, can solve the problems of repeated soil sampling, low efficiency, soil sample falling off, etc., and achieve the effects of improving sampling efficiency, simple structure and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

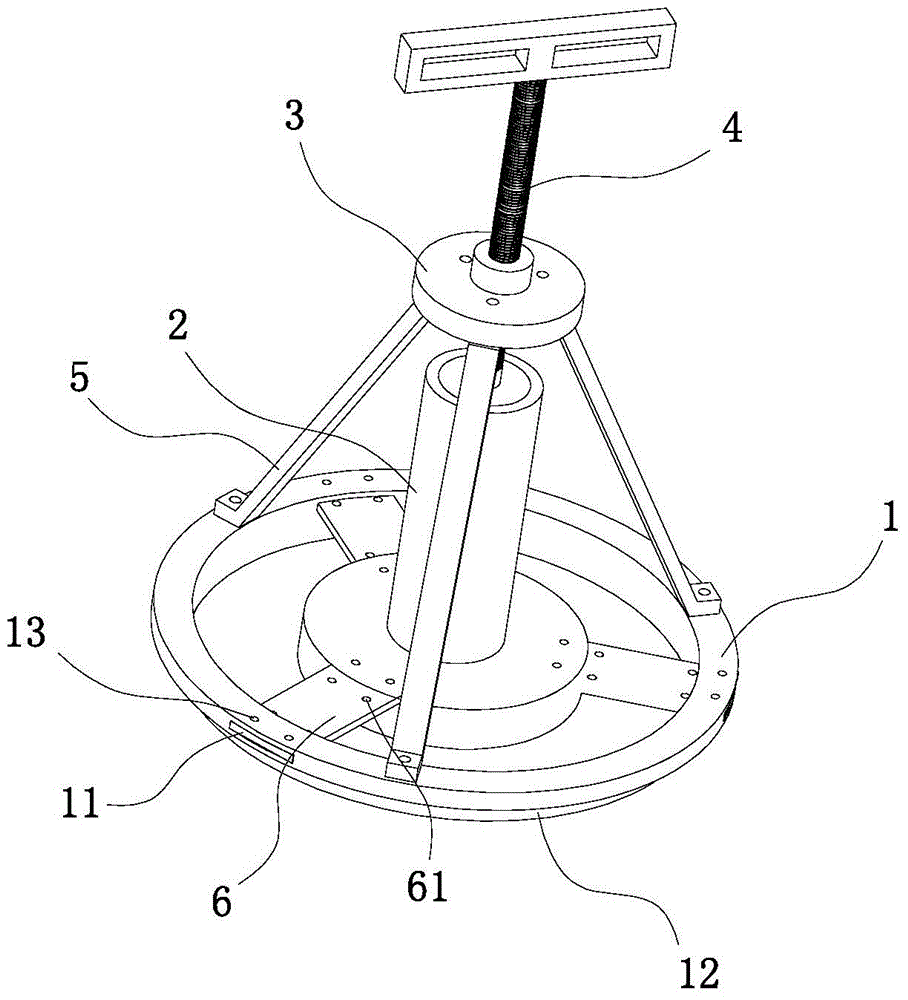

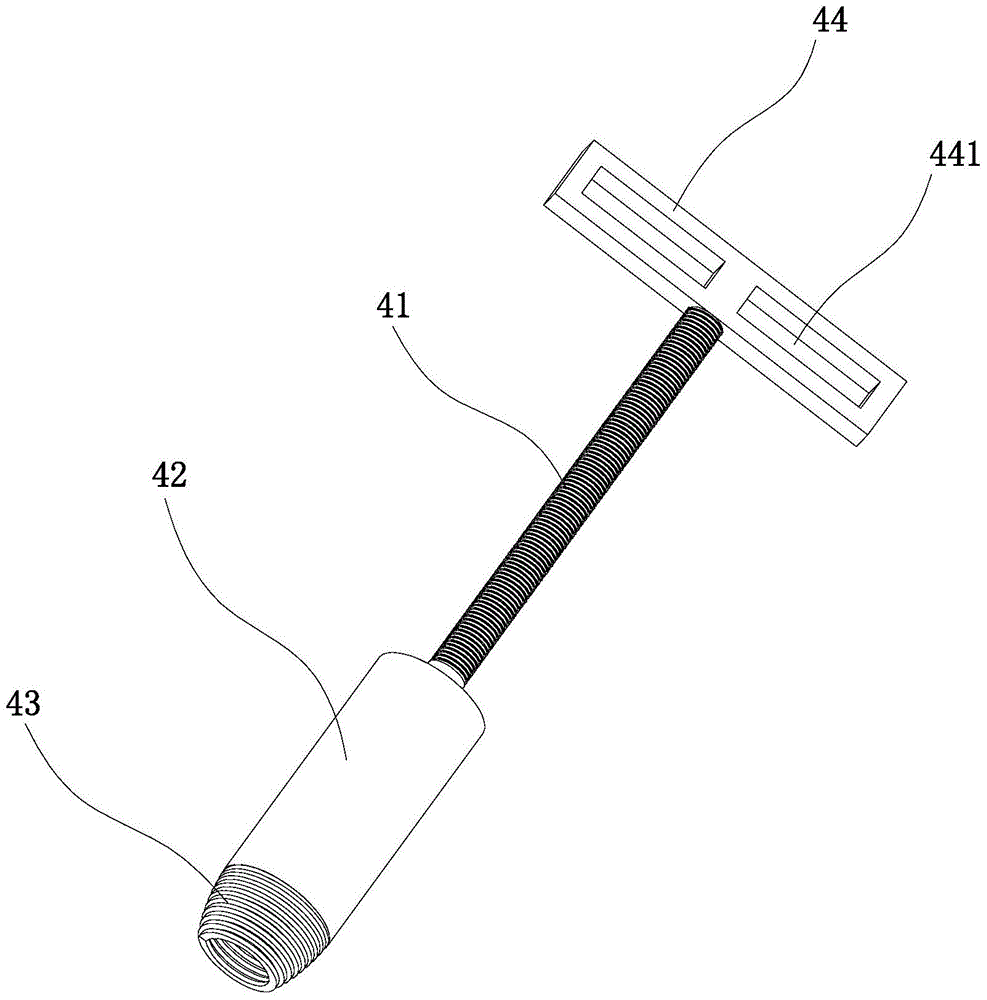

[0020] Such as figure 1 As shown, the high-efficiency earth taker of the present embodiment comprises an annular base 1, the center of the base 1 is fixedly connected with a guide seat 2 by means of a connecting plate 6, and the central sliding device of the guide seat 2 takes soil rod 4, and the soil fetch rod 4 is The upper end has a screw mandrel 41 and the lower end has a structure with a soil-taking cover 42. The screw mandrel 41 is spirally connected in the screw mandrel seat 3. The screw mandrel seat 3 and the circular base 1 are fixedly connected by a plurality of fixing rods 5. The screw mandrel 41 The upper end of has handle 44, and the lower end of earth taking cover 42 is connected with conical sleeve 43.

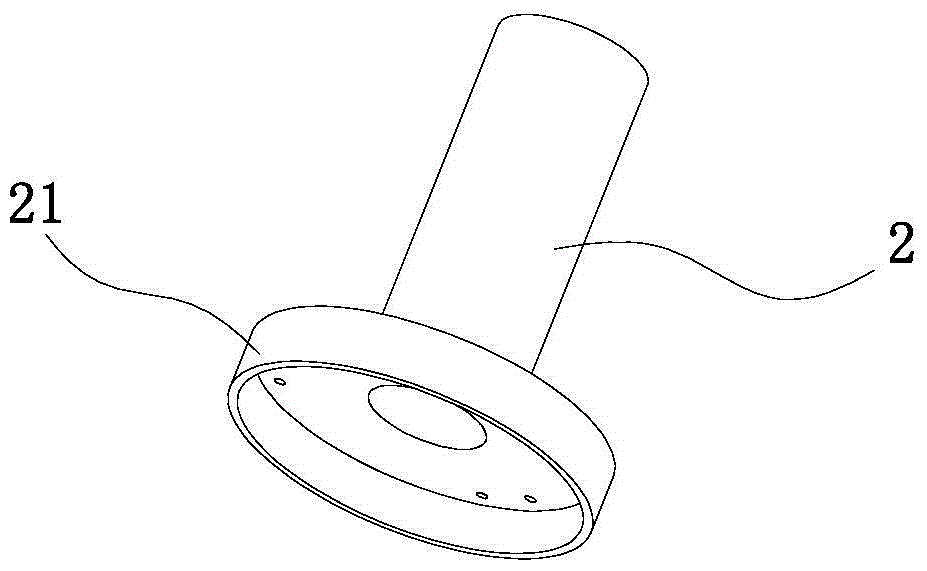

[0021] Such as figure 2 As shown, the lower surface of the guide seat 2 has a second annular flange 21 .

[0022] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com