A double-headed live working cable clamp

A technology of live work and wire clamps, which is applied to the installation of electrical components, cables, and cable suspension devices, etc., can solve the problems of difficult operation, many operating levers, cumbersome and complicated operations, etc., to improve mechanical strength and electrical performance, Convenient and reliable fixation and cancellation of the effect of the wire clamp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. While the invention will be described in conjunction with the preferred embodiments, it will be understood that it is not intended to limit the invention to the described embodiments. On the contrary, the invention is to cover alternatives, modifications and equivalents, which may be included within the scope of the invention as defined by the appended claims.

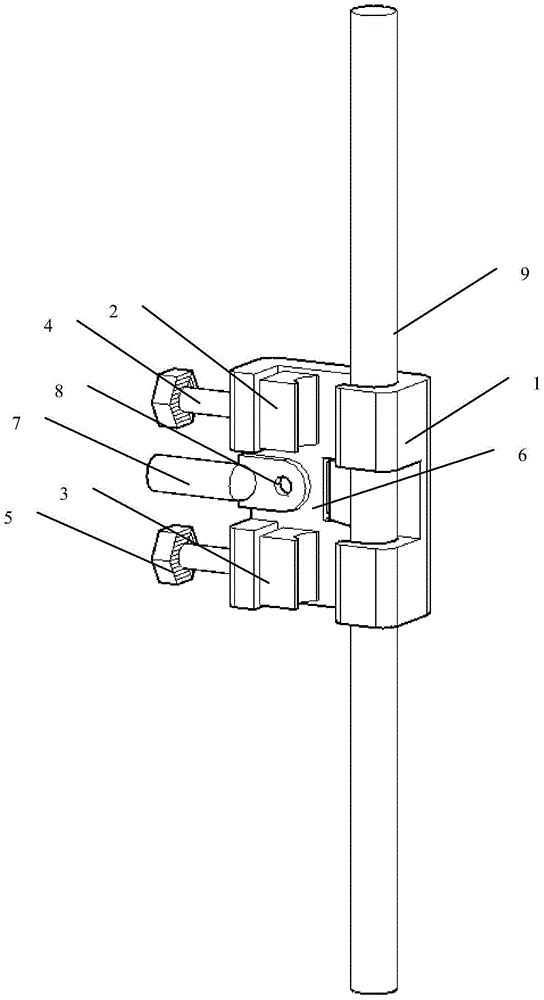

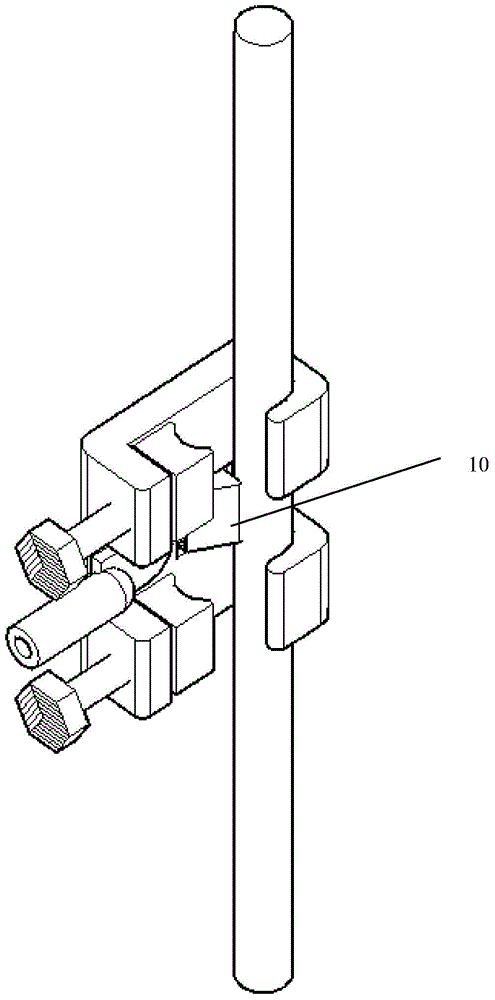

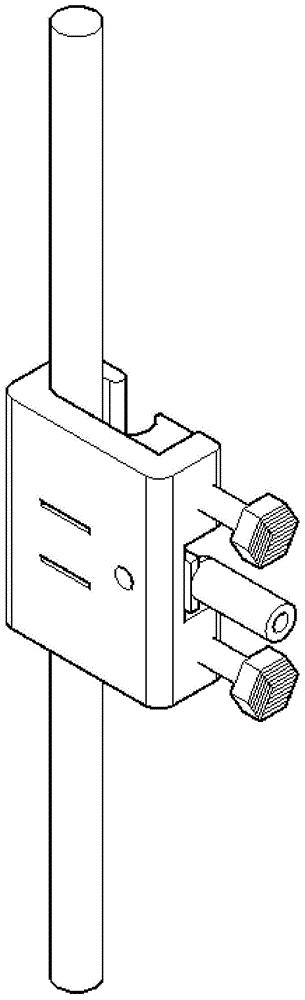

[0012] The double-headed live work connection clamp of this embodiment includes a C-shaped clamp 1, a first sliding clamp 2 and a second sliding clamp 3; the C-shaped clamp 1 is provided with two side-by-side gaps. C-shaped hook; the gap between the two C-shaped hooks of the C-shaped wire clamp 1 is provided with a stopper 10, and the cross-section of the stopper 10 is a right triangle, protruding from the gap of the C-shaped wire clamp 1, The limiter 10 is provided with an elastic member, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com