Shield sleeve and shielding end element comprising a shield sleeve

A technology of shielding sleeves and sleeves, which is applied to the parts, electrical components, coupling devices and other directions of the connecting device, can solve the problem of high contact impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

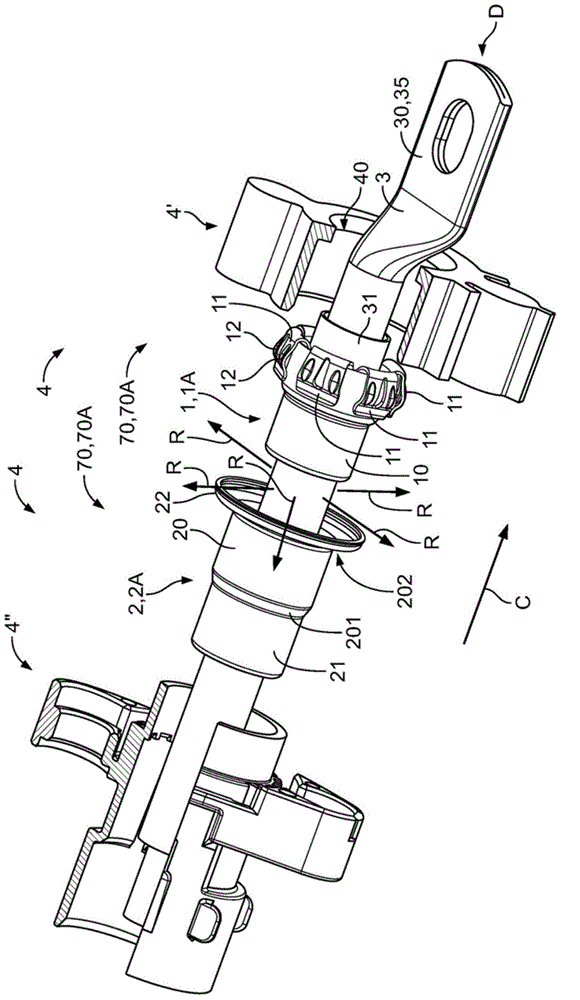

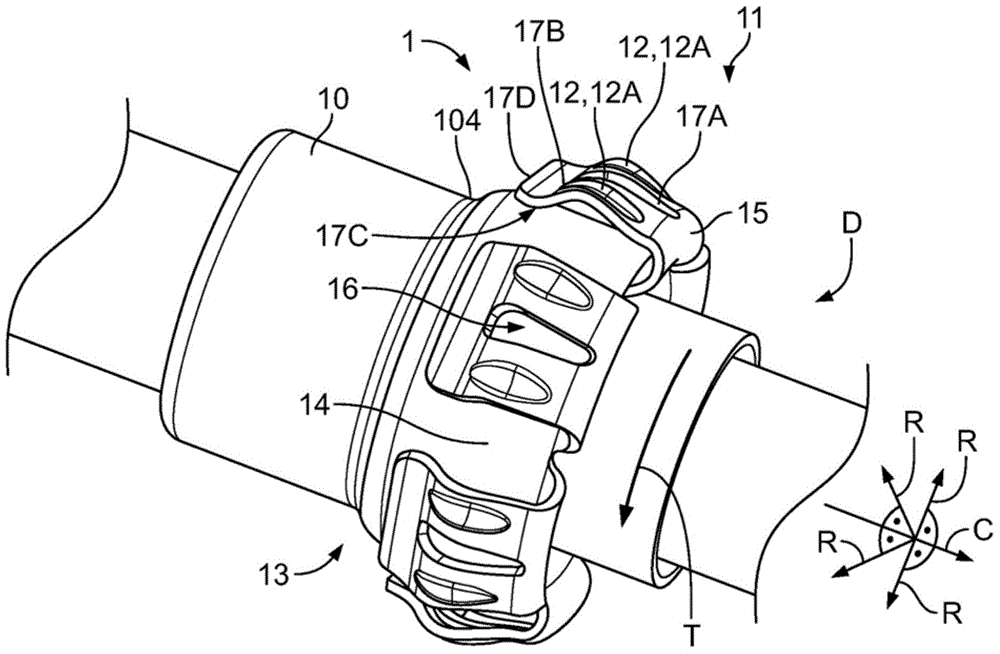

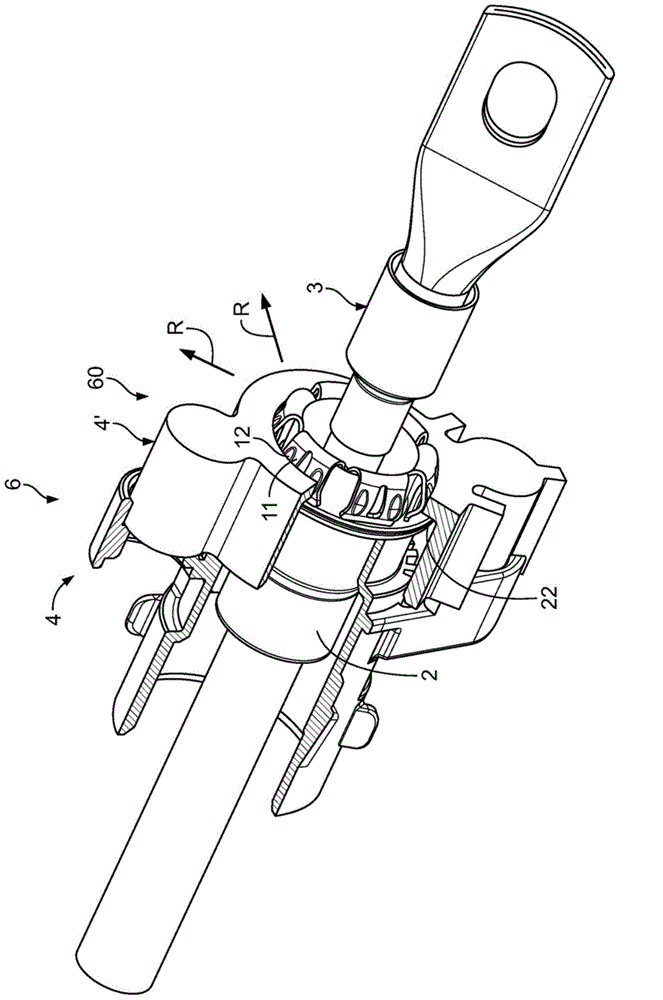

[0040] figure 1 is a perspective view of a first embodiment 1A of a shielding sleeve 1 according to the invention and a first embodiment 2A of a crimping sleeve 2 according to the invention, a cable 3 and a housing 4 comprising a first housing Part 4' and a second housing part 4". The housing parts 4', 4" are shown in partial cutaway. exist figure 1 A pre-assembled state is shown in where connections have not yet been made between the individual elements. The shielding sleeve 1 and the crimping sleeve 2 are assembled on the cable 3 and arranged forward and backward along the direction C of the cable.

[0041] The cable 3 comprises an inner conductor 30, an intermediate insulating material 31 and a cable shield (not shown) located outside the intermediate insulating material 31 and surrounded by an outer insulation (not shown). At the distal end D of the conductor 30 of the cable 3 is arranged a contact portion 35 for making contact with another element (not shown).

[0042...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com