Automatic production equipment for spiral steel pipe with spiral reinforcing ring

A technology of spiral steel pipe and production equipment, applied in other manufacturing equipment/tools, manufacturing tools, etc., to achieve the effects of improving welding quality, convenient adjustment and fixing, easy pressure test and leak detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be further described below.

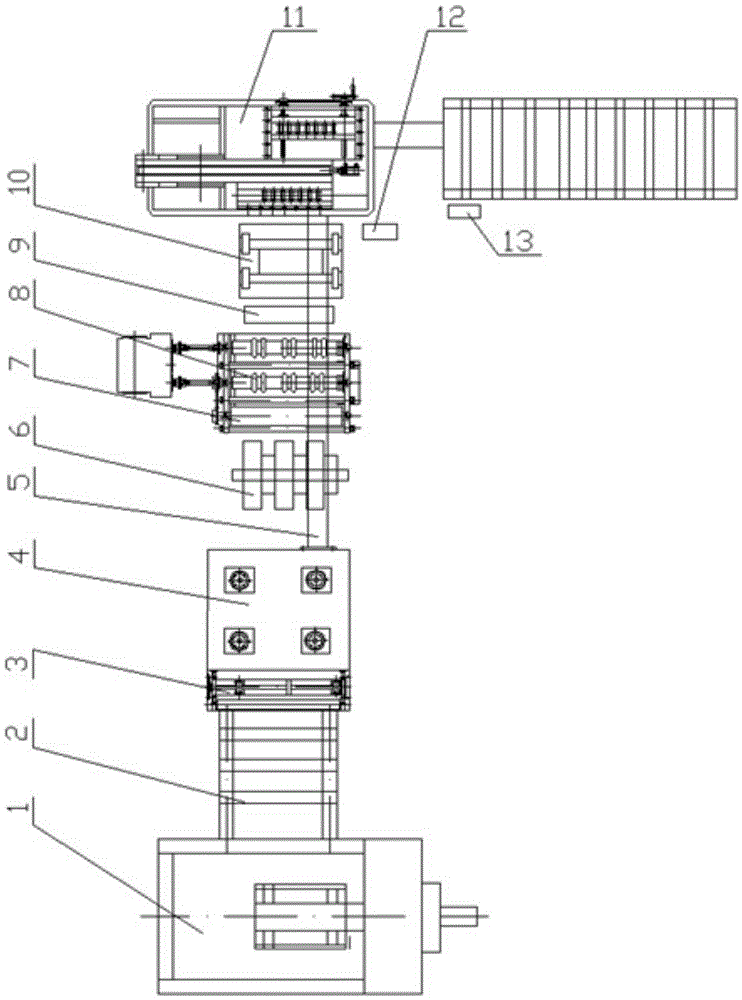

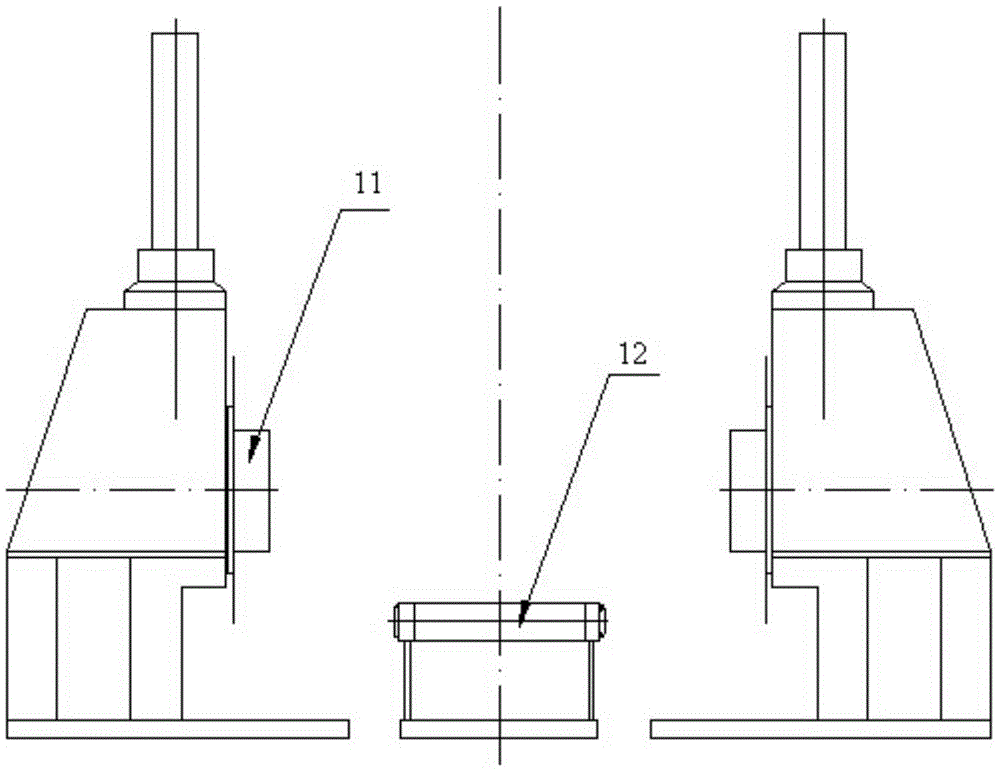

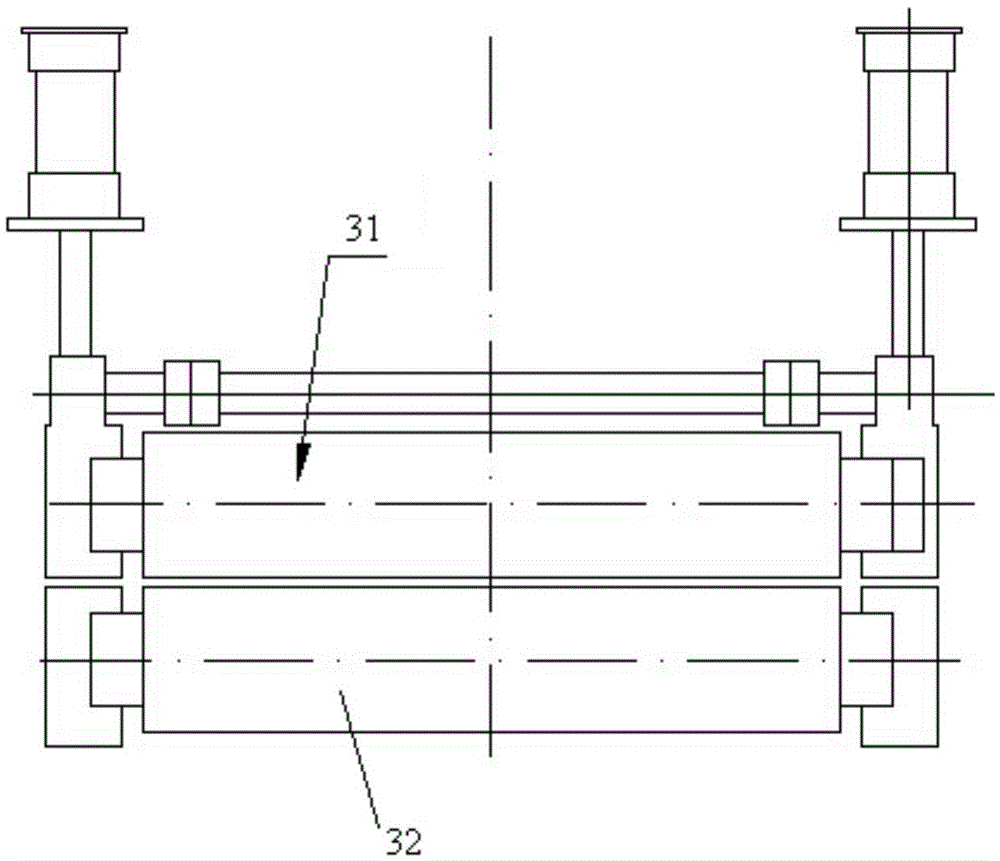

[0038] Such as figure 1 As shown, the automatic production equipment of the present invention includes the first put turn frame 1 for setting the main steel strip connected in sequence, the feeding bracket 2 for conveying the main steel strip 14, the first pinch roller device 3, the straightening Flat roller device 4 and rotating beam 5; the rear of the rotating beam 5 is located above or below the plane where the main steel belt 14 is located, and is also connected in turn to the second turn frame 6 and the second pinch roller device for setting the narrow steel belt 15 7 and a forming device 8 for bending the narrow steel strip, and the forming device 8 sends the formed narrow steel strip 15 (i.e., the reinforcement ring 16) into the main steel strip 14 through the guide device 9, and the main steel strip 14 and The reinforcing ring 16 passes through the clamping device 10 , the spiral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com