Vehicle body large part positioning tool with template switching function

A technology for positioning tooling and template switching, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of inability to use the template for large parts of the car body, delay production progress, time-consuming and labor-intensive efficiency, etc., to achieve convenient and fast operation process and save production. cost, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

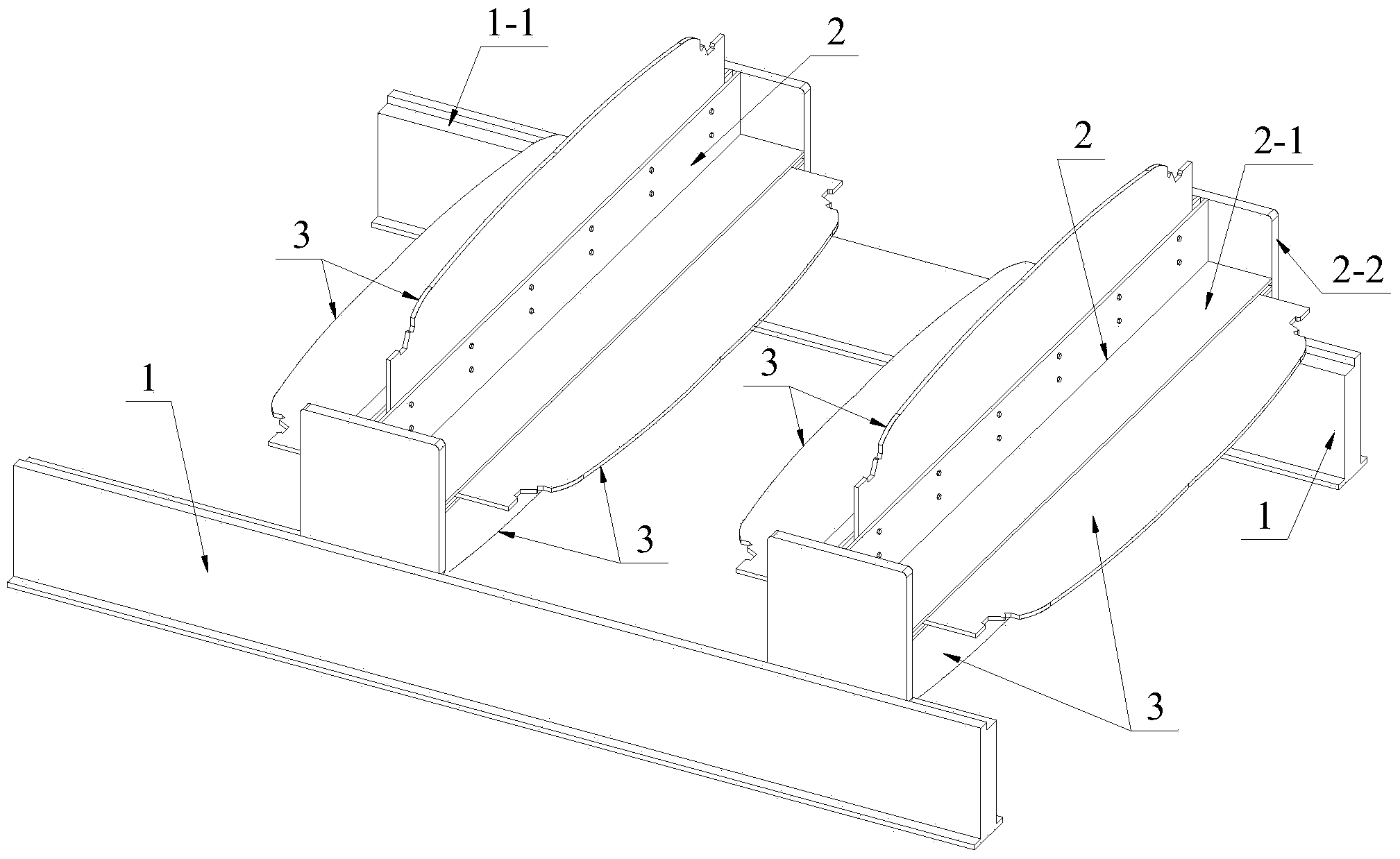

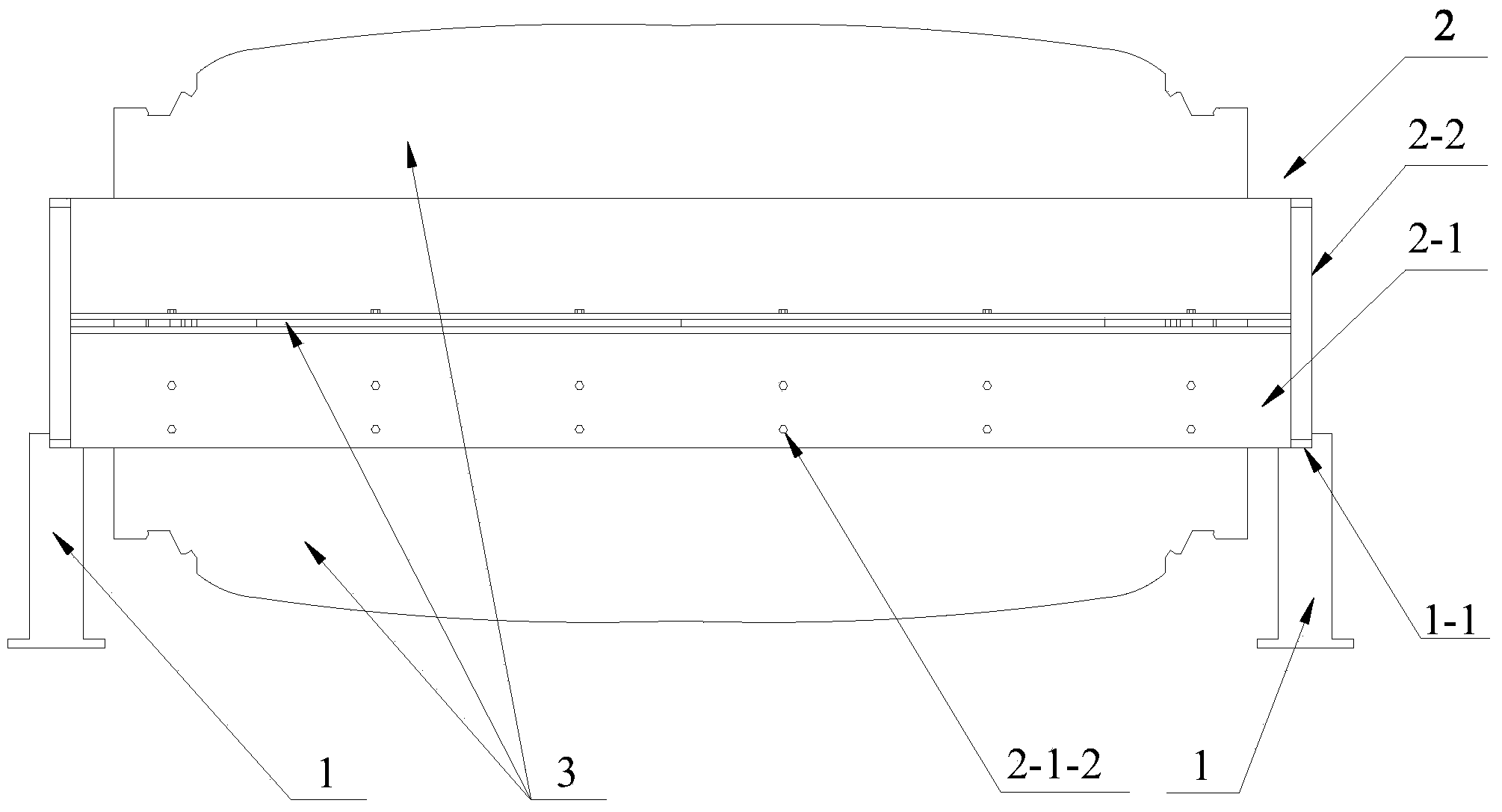

[0016] Such as Figure 1 to Figure 5 As shown, the car body large part positioning tool with template switching function of the present invention includes: double guide rail 1 and template positioning seat 2, double guide rail 1 includes two identical guide rails, and the upper end surface of the guide rail is provided with an outer stopper. In the chute 1-1, two identical guide rails are placed in parallel and symmetrically, and the distance between them is the same as the length of the template positioning seat 2.

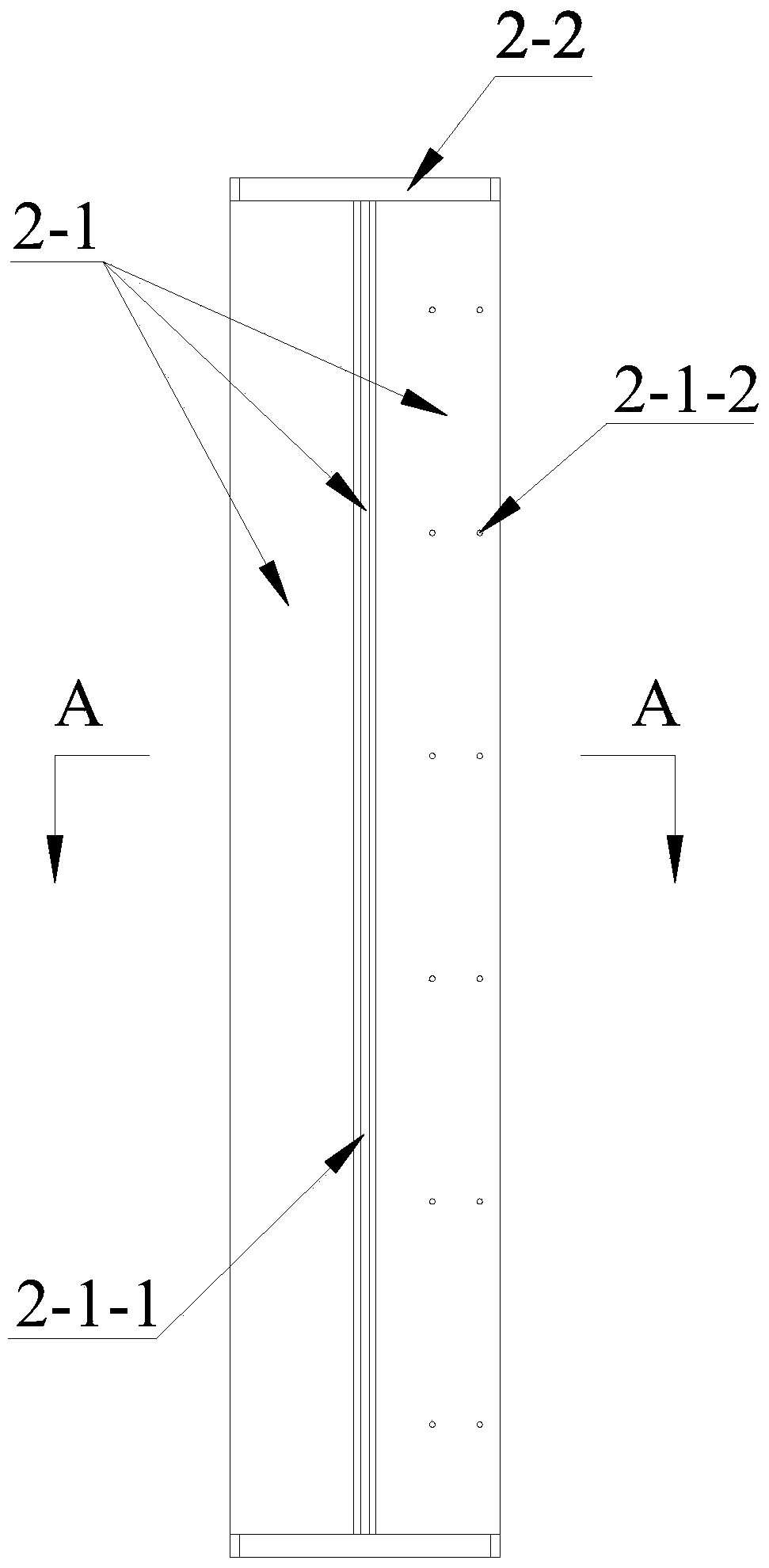

[0017] The template positioning seat 2 includes two square baffles 2-2 and a splint assembly 2-1, and the splint assembly 2-1 includes four splints 2-1-1 with through grooves and a plurality of template positioning screw holes 2-1-2, the four splints 2-1-1 are integrally formed and spaced from each other at a circumferential angle of 90 degrees...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com