Bark peeling machine

A technology for peeling machines and logs, which is applied in the direction of bark, wood processing equipment, manufacturing tools, etc. It can solve the problems of defective adjustment ability and low automation of peeling machines, and achieves simple structure, strong working ability and good adjustment degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

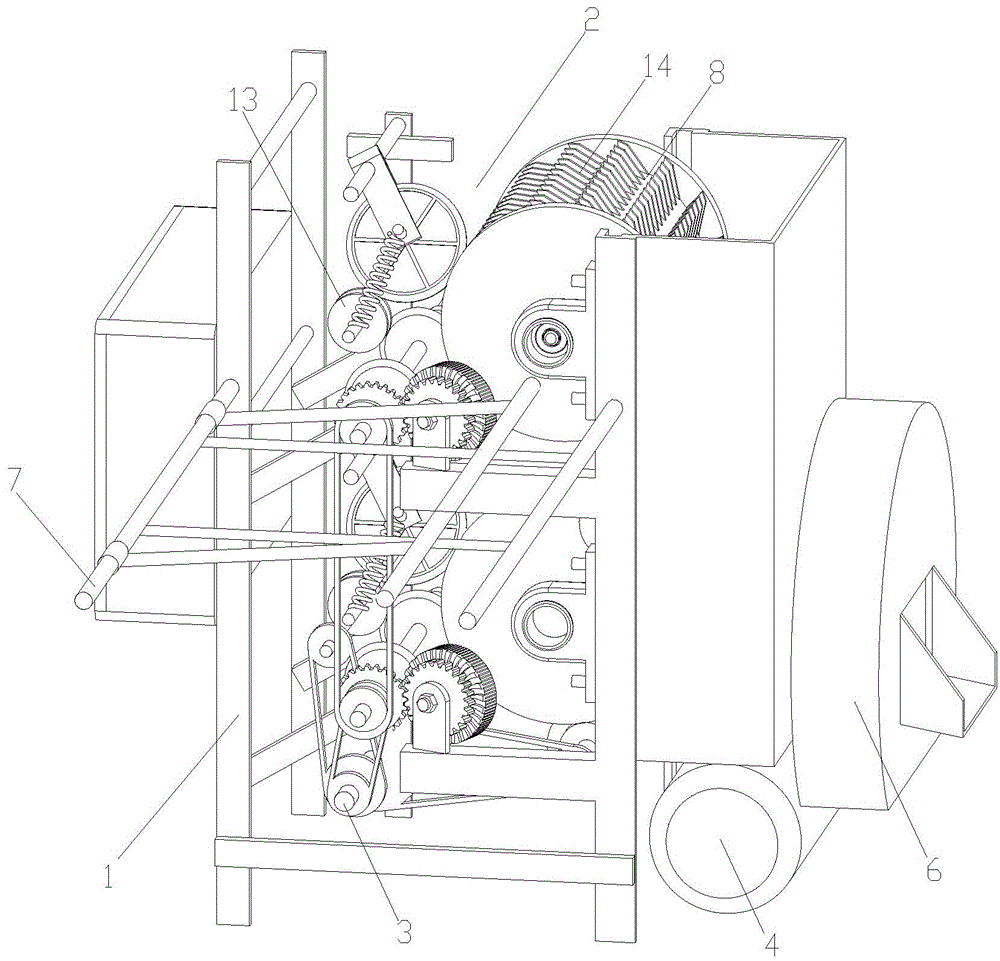

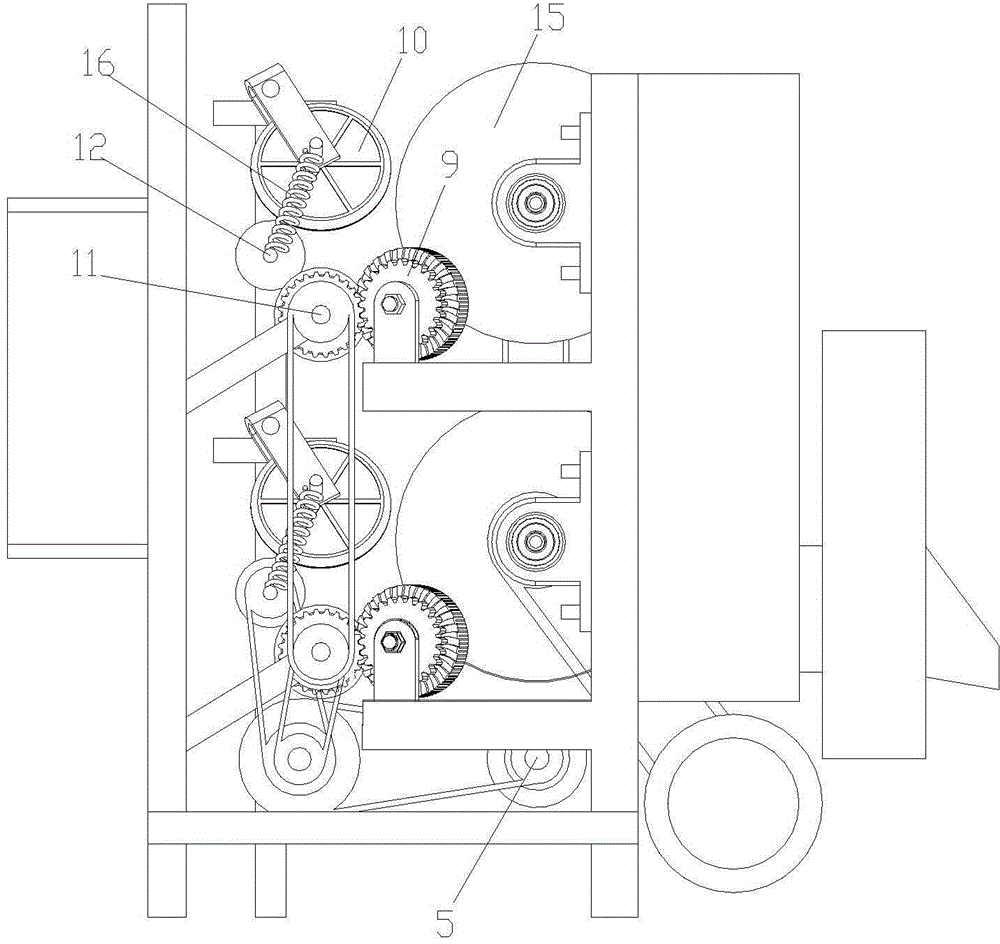

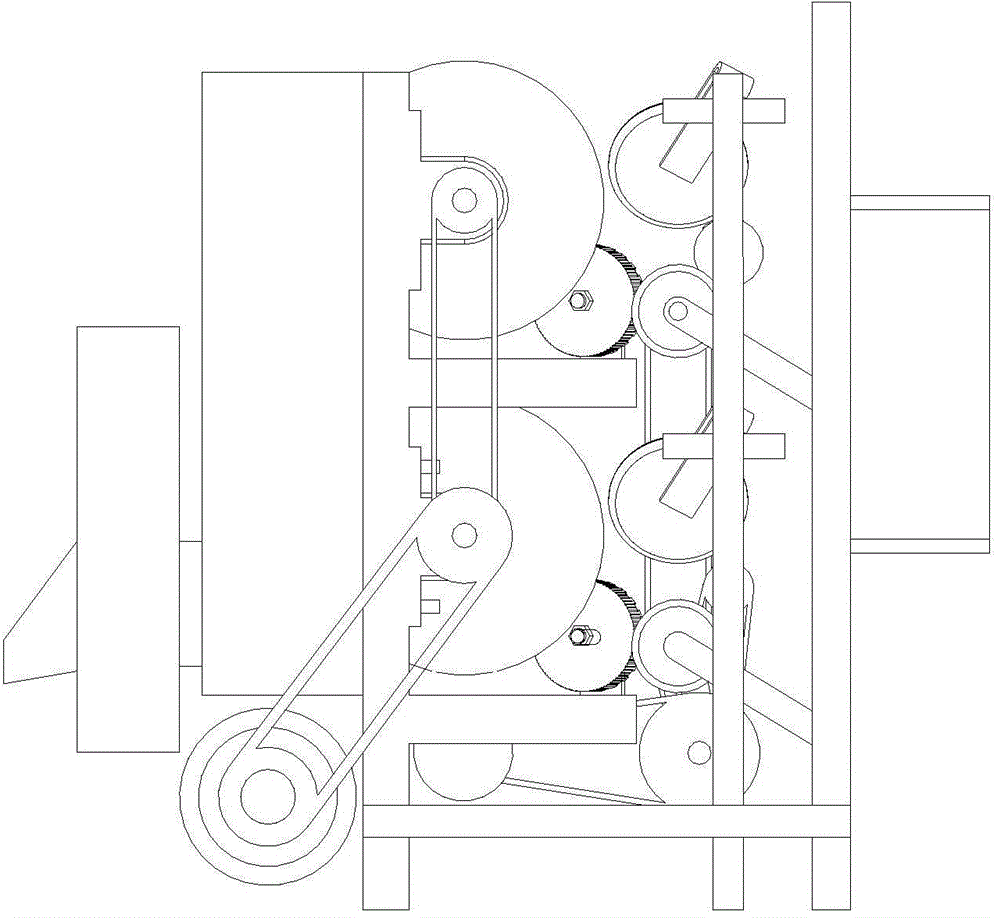

[0017] Please refer to the attached Figures 1 to 3 , the embodiment of the present invention includes:

[0018] A log peeling machine, comprising a frame 1, a synchronously driven upper and lower two sets of peeling mechanisms 2, a main power transmission shaft 3, a first motor 4, a second motor 5, a funnel 6, and a discharge rack 7; The structure of group peeling mechanism 2 is identical, and it comprises hob 8, oblique feeding wheel 9, pressing wheel 10, first shaft 11 and second shaft 12; Hob 8, oblique feeding wheel 9, pressing wheel 10 It is distributed in a character shape and clamps the wood between the three together; the pressure wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com