Hydraulic controller for filter press

A technology of hydraulic controller and filter press, which is applied in the direction of mechanical equipment, fluid pressure actuation device, fluid pressure actuation system safety, etc. It can solve the problems of poor standardization, single product, versatility, and low reliability. Achieve the effect of maintaining sealing performance, large area ratio and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

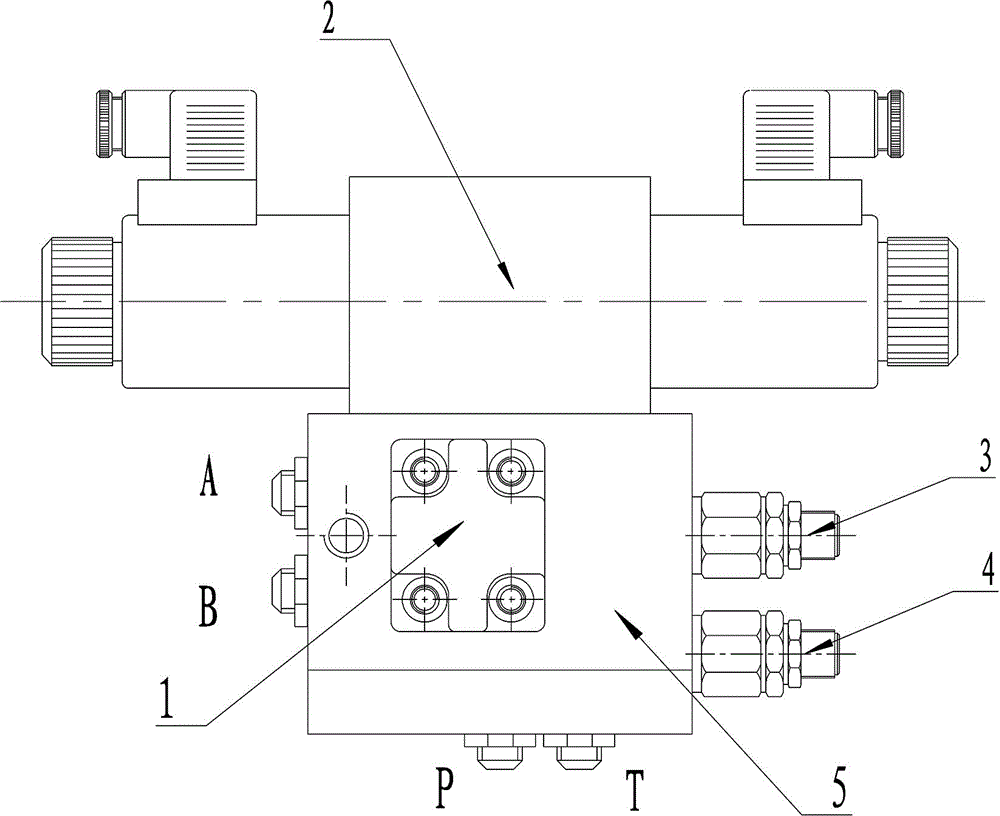

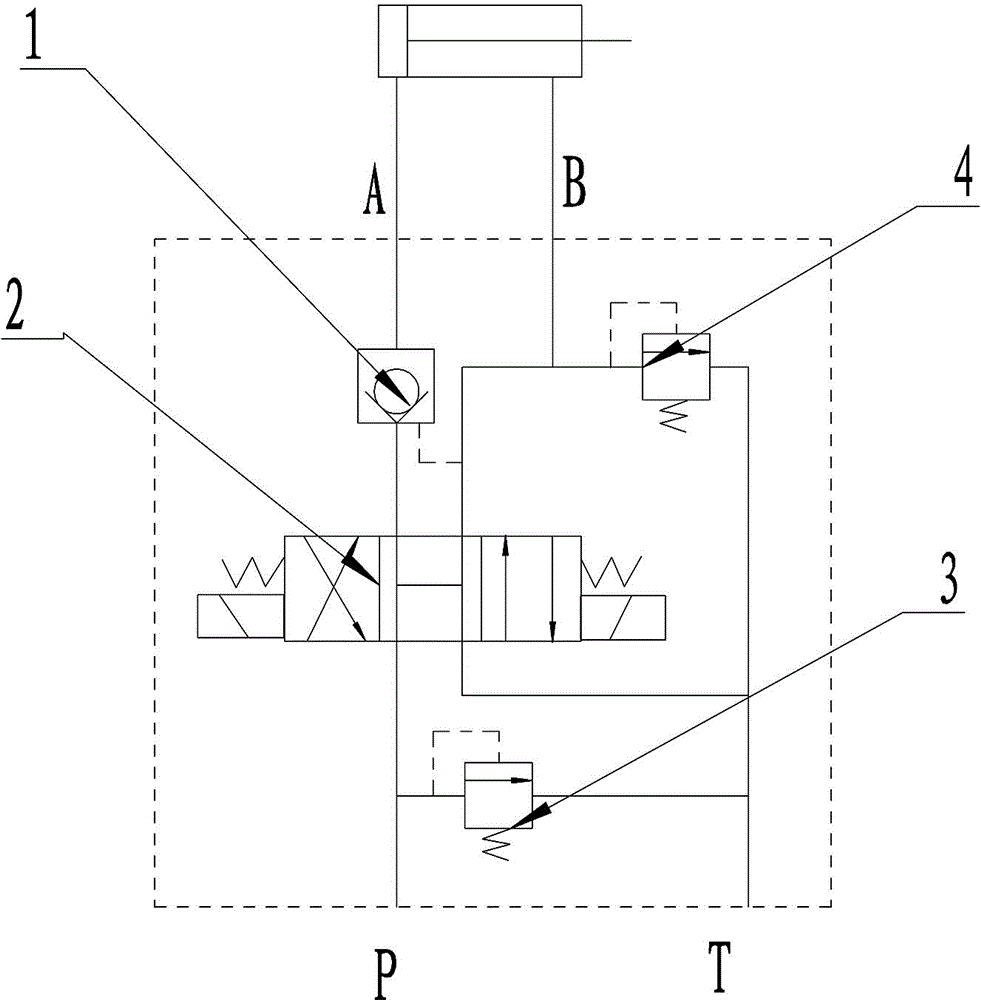

[0015] Such as figure 1 Shown: The hydraulic controller of the filter press includes a hydraulic lock 1, a directional control valve 2, a high-pressure safety valve 3, a low-pressure safety valve 4 and an oil circuit block 5, in which the hydraulic lock 1 is inserted into the oil circuit block 5 and passes through the O-shaped The sealing ring is blocked, the high-pressure safety valve 3 and the low-pressure safety valve 4 are plug-in components, which can be directly inserted into the oil block (because the component comes with an O-ring, it can be directly inserted into the oil block), the direction control valve ( Manual valves, explosion-proof valves, solenoid valves (optional) can also be used to install directly on the oil block through screws.

[0016] According to the above structure, the filter press hydraulic controller works as follows: figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com