Novel triaxial test soil sample preparation system

A technology of triaxial test and preparation system, applied in the field of geotechnical testing, can solve the problems of uneven density of soil samples, insufficient compaction, and difficulty in fixing the sample cylinder, so as to improve the accuracy and efficiency, and improve the success rate of opening the cylinder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

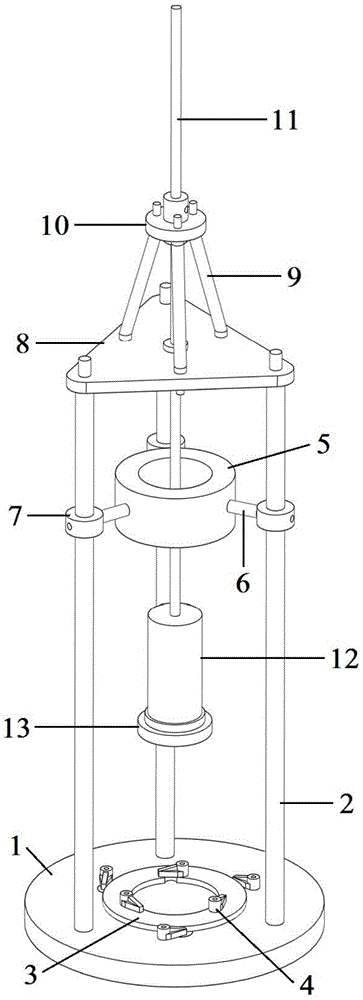

[0047] First adjust the compaction device according to the sample preparation specifications. Select the lower positioning chuck 3 suitable for the φ61.8mm×125mm sample, install it into the base 1, press the three T-shaped bayonet pins 4 on the base 1 on the lugs of the lower positioning chuck 3, and tighten it with butterfly bolts fixed. Select the positioning sleeve 7, tighten the positioning bolts on the main pillar collar 7, temporarily fix the sleeve system at a high position, and then put it down and fix it after placing the sample cylinder. Select the hammer 16 and the hammer bottom plate 19, install it on the hammer guide rod 11, lift the hammer system and fix it with the limit bolt on the top positioning ring 10, and put it down when it is ready to hit.

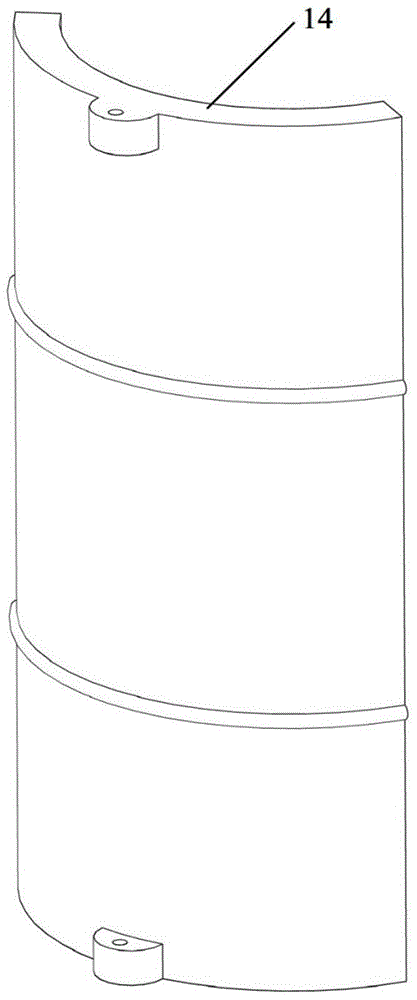

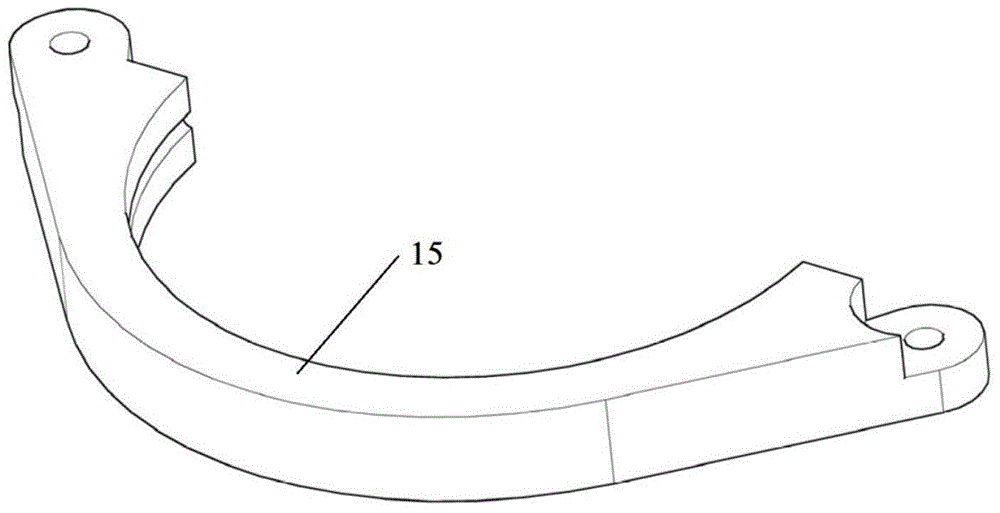

[0048] Select a three-lobed sample striking cylinder 14 and four split hoops 15, put the split hoops 15 on the sample striking cylinder 14, and fix them with bolts. Put the fixed knockout cylinder into the lower po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com