Process capable of increasing CaO comparison yield in fluorescence analysis limestone

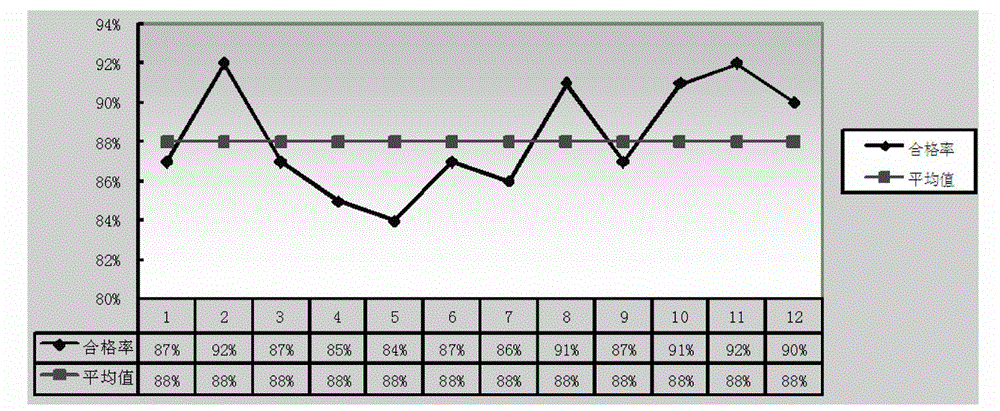

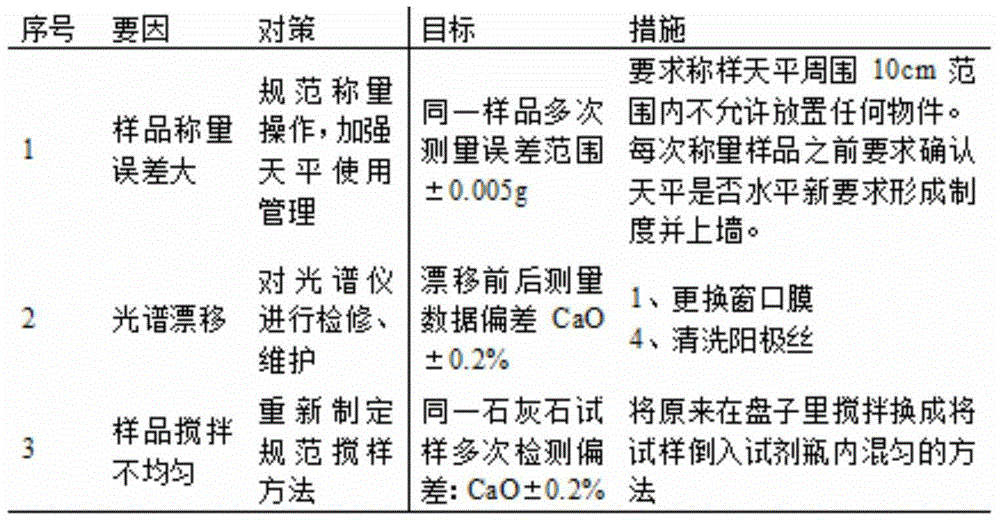

A fluorescence analysis, limestone technology, applied in the direction of analyzing materials, material analysis using wave/particle radiation, measuring devices, etc., can solve the problems of large sample weighing error, uneven sample stirring, large spectral drift, etc. The effect of large quantitative error, improved contrast pass rate, and small spectral drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0033] According to an embodiment of the present invention, a process capable of improving the pass rate of fluorescence analysis of limestone CaO comparison is provided, including:

[0034] a. Make sure that no objects are placed within 10cm around the balance;

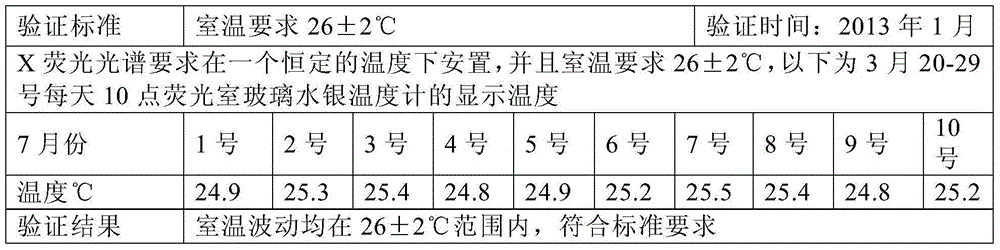

[0035] b. Adjusting the amount of spectral drift; Step b specifically includes:

[0036] (1) Check the spectrometer operation records to ensure that the detection gas flow rate is between 0.9-1.0L / M, and the gas pressure is always between 750±5MPa;

[0037] ⑵ Cleaning and maintenance of the spectrometer; the operation of cleaning and maintenance of the spectrometer includes: cleaning the anode wire; repla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com