Technology for improving comparison yield of fluorescence analysis raw materials

A technology of fluorescence analysis and pass rate, which is applied in the analysis of materials, material analysis using wave/particle radiation, and measuring devices, etc., can solve the problems of low pass rate, high failure rate, poor stability, etc. Low rate, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Implementation 1. In view of the problem of many failures of mills and tablet presses, we have conducted an analysis:

[0062] It was found that the bottom of the grinding seat was fixed by several screws. Due to the daily vibration, the screws became loose or even broke, causing grinding and dust. We welded the bottom of the disc grinding seat, so there will be no more loose screws; at the same time, we found that the tablet press made the sample crack because the pressure of the tablet press was not enough. Therefore, we found out the appropriate pressure through experiments and comparisons for specific mills. ; When the mold is damaged and cannot be used, contact the manufacturer to repair and replace the mold.

[0063] Grinding machine, tabletting machine due to verification effect table

[0064]

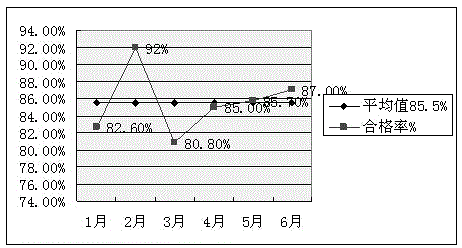

[0065] Depend on Figure 7 It can be seen that from January to July 2012, the operation rate of the mill and tablet press before the activity was low, with an aver...

Embodiment 2

[0066] Implementation 2. We analyzed the problem of low fluorescence operation rate:

[0067] The raw material sample is dusty because the vacuum cleaner failed to clean it in time, resulting in insufficient suction of the vacuum cleaner. When the raw material was detected, the spectrometer could not accurately analyze the actual strength of each element in the material, which directly caused the fluctuation of the ingredients. Therefore, We arrange specific post personnel to clean the vacuum cleaner every day. When the vacuum cleaner is normal, if there are still powder samples around the steel ring of the raw sample and on the surface of the sample, the post personnel will be punished financially.

[0068] Verification effect table of reasons for low operating rate of spectrometer

[0069]

[0070] Depend on Figure 8 It can be seen that from January to July 2012, the operating rate of the spectrometer before the event was low, with an average of 82.50%, and the fluctuat...

Embodiment 3

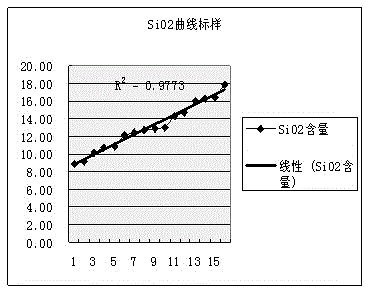

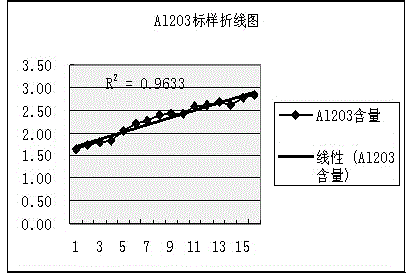

[0071] Implementation 3. We analyzed the problem that the grinding aid triethanolamine has a great influence on the chemical composition of the raw meal:

[0072] Research has found that grinding aids have an impact on the strength of elements in raw meal samples. Therefore, we must control the amount of triethanolamine added within a certain range, and the biggest factor that affects the constant amount of triethanolamine added is the breakage of the burette and the post personnel. In this regard, we require that once the burette is damaged, the post must be replaced immediately, and the correct method of adding triethanolamine must also be practiced during the post assessment.

[0073] Grinding aid factor verification effect table

[0074]

[0075] The pass rate of raw meal comparison has reached an average of 92.3%, which is higher than the predetermined target value of 90%, indicating that the pass rate of raw meal element comparison has increased, and the activities ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com