High-low-high split type lining board for semi-autogenous mill barrel and operation method

A semi-autogenous mill and high-fraction technology, which is applied in the direction of grain processing, etc., can solve the problems that the grinding medium and materials cannot be lifted, the integrated liner loses the lifted material, and the cylinder liner replacement cycle is short, etc., to achieve Improve the effect of materials and grinding media, continuous and stable processing capacity, and improve grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

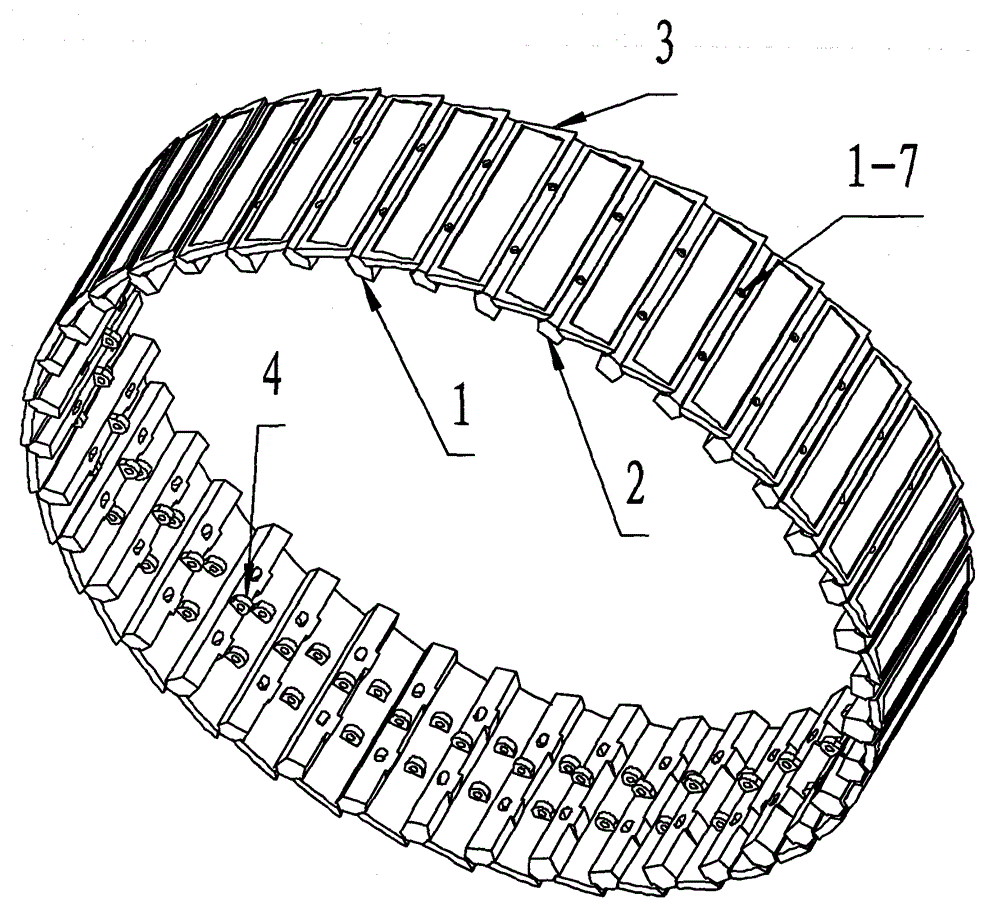

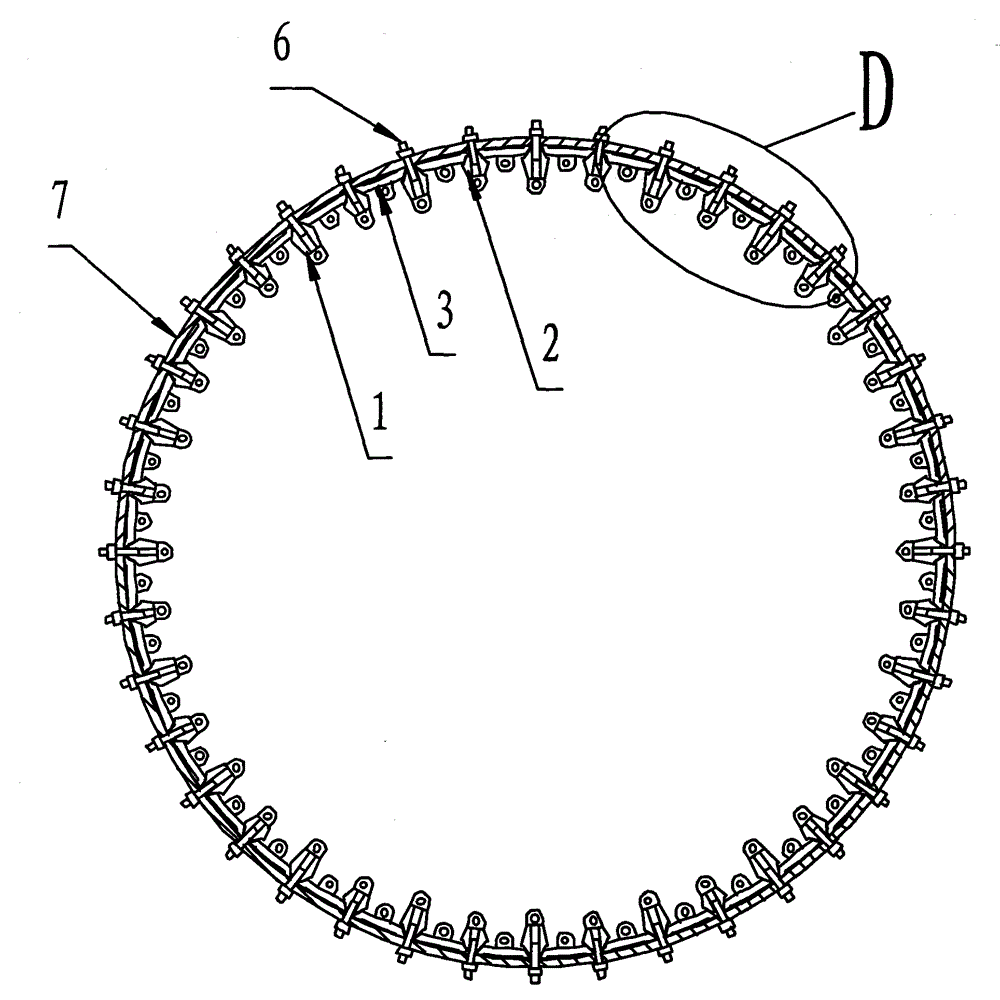

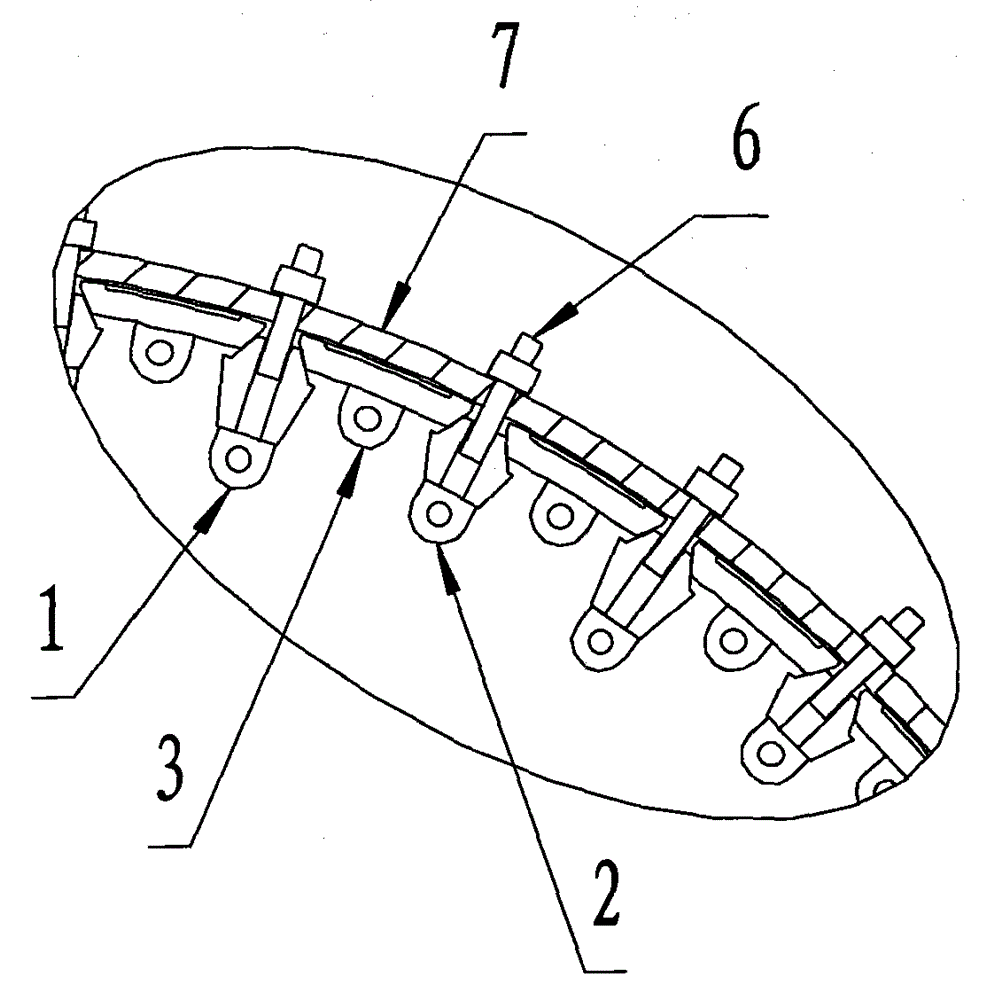

[0027] Low-type bead 2 is arranged on both sides of high-type bead 1, and bottom plate 3 is arranged between high-type bead 1 and low-type bead 2. In the order of base plate 3 and low bead 2, the high bead 1, base plate 3, and low bead 2 are combined to form a ring-shaped split liner, and a pair of bolts are installed on the high bead 1 and the low bead 2. Holes 1-7, the closing bolts 6 are arranged in the closing bolt installation holes 1-7, and the split liner is fixed in the cylinder body 7 by the closing bolts 6.

Embodiment 2

[0029] The high-type layer 1 and the low-type layer 2 are composed of: layer body 1-1, upper plane 1-2, lower plane 1-3, hypotenuse 1-4, matching bevel 1-5, grinding bevel 1- 6. Composed of bolt mounting holes 1-7, lifting lugs 4, and hanging holes 5; upper and lower planes 1-2 and lower planes 1-3 are set above and below the bead body 1-1, and lifting lugs are set in the middle of the lower plane 1-3 4. Hanging holes 5 are set in the lifting lug 4, a pair of bolt mounting holes 1-7 are symmetrically set on both sides of the lifting lug 4, hypotenuses 1-4 are set on both sides of the bezel main body 1-1, and two hypotenuses 1 Two matching slopes 1-5 are correspondingly arranged between the inner side of -4 and both sides of the upper plane 1-2, and two grinding slopes 1-5 are correspondingly arranged between the outer sides of the two hypotenuses 1-4 and both sides of the lower plane 1-3. 6. The two sides are arranged symmetrically with the slopes 1-5; the two slopes 1-4 are s...

Embodiment 3

[0031]The base plate 3 is composed of: base plate main body 3-1, upper plane 3-2, lower plane 3-3, groove 3-4, side surface 3-5, positioning slope 3-6, lifting lug 4, hanging hole 5 Composition; upper and lower planes 3-2 and lower planes 3-3 are set on the upper and lower sides of the base plate main body 3-1, grooves 3-4 are set in the upper plane 3-2, side surfaces 3-5 are set on both sides of the base plate main body 3-1, The two sides 3-5 and the upper plane 3-2 form an included angle of 90 degrees, two positioning slopes 3-6 are correspondingly arranged between the two sides 3-5 and the lower plane 3-3, and a pair of positioning slopes are arranged on the lower plane 3-3. The hanging lug 4 is provided with a hanging hole 5 in the hanging lug 4; the two sides are arranged symmetrically with the slope 6; the groove 4 is rectangular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com