Device for machining workpieces

A technology for processing workpieces and driving devices, which is applied in the field of devices for processing workpieces, and can solve the problems that the outer diameter and inner diameter cannot be processed, and the diameter range cannot be processed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

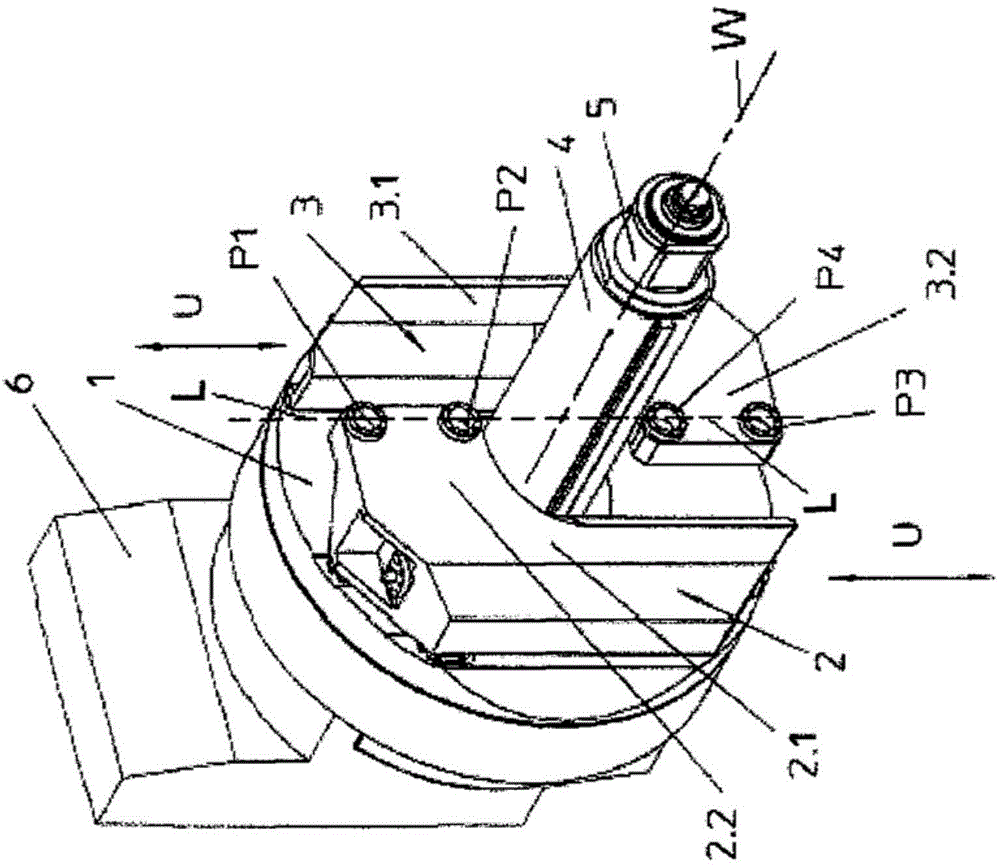

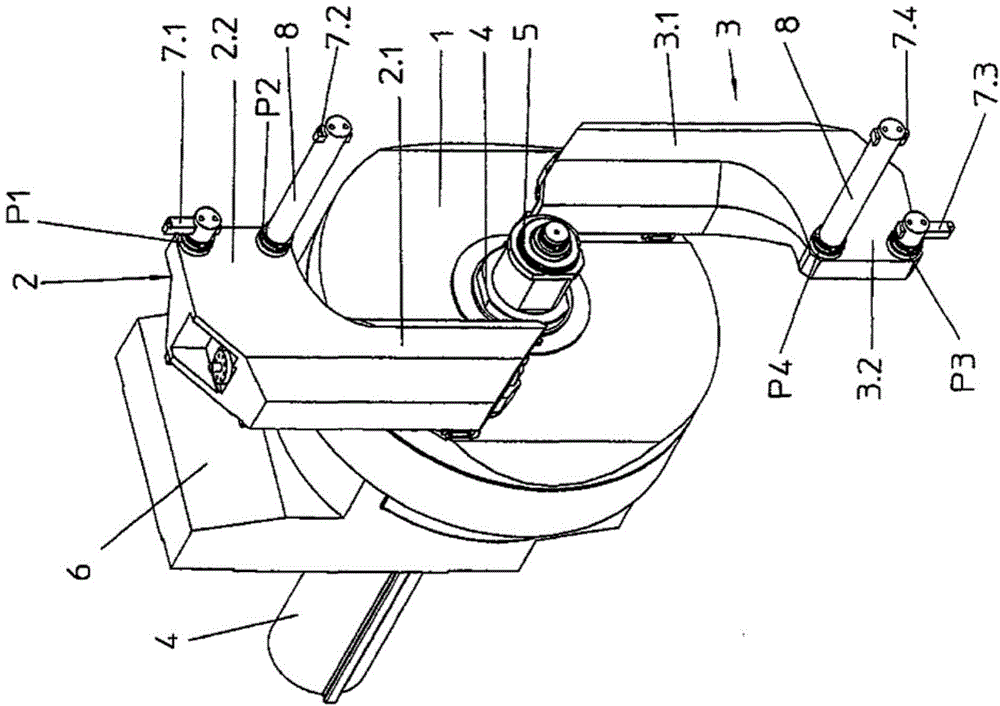

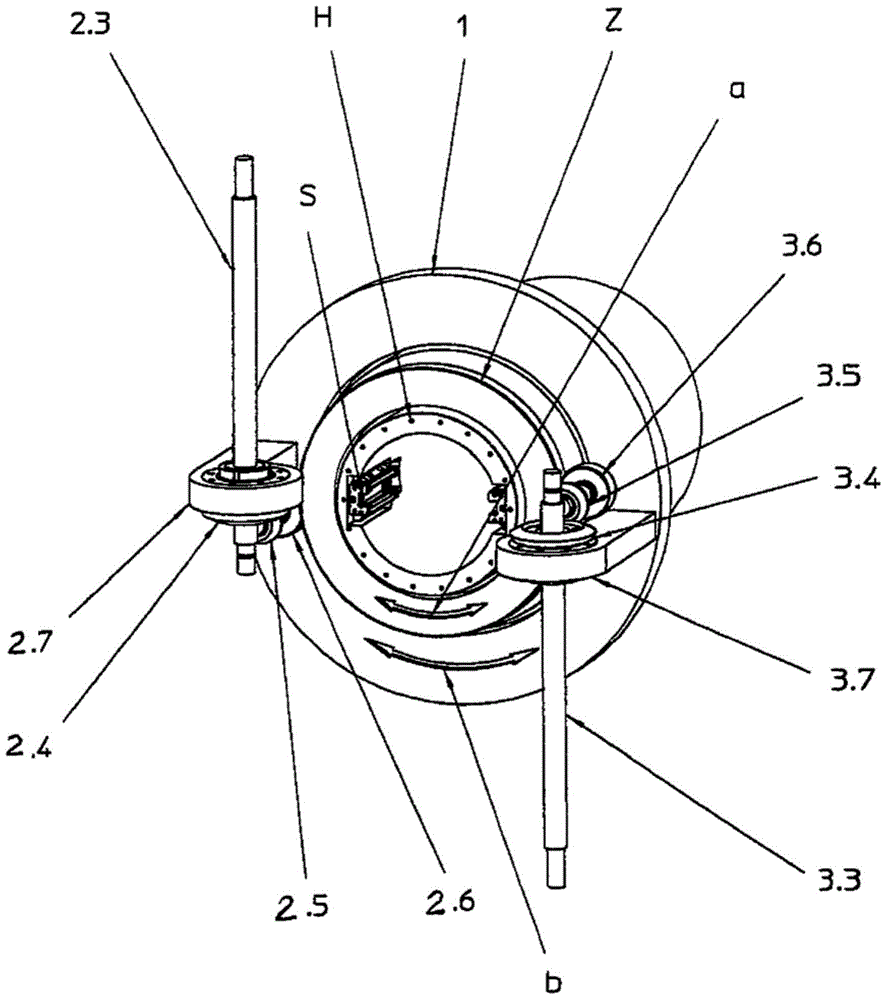

[0036] exist figure 1 shows a device according to the invention with a faceplate 1 on which a first cross slide 2 and a second cross slide 3 are arranged in a radially inwardly displaced end position. The rectilinear and mutually parallel adjustability of the cross slides 2 and 3 along the respective longitudinal axes U is achieved via linear guides not shown here. Faceplate 1 is rotatable around a rotation axis W and by means of a column (see Figure 11 ) is linearly movable along a Z axis Z, which extends parallel to the axis of rotation W. one in figure 1 The working spindle 5 of the horizontal machining center not shown in the figure protrudes through the face plate 1 and the cross tool rest 4 . The faceplate 1 is fixed by means of a guide 6 .

[0037] The first cross-slide 2 has a guide area 2.1 from which an angled arm 2.2 extends in the direction of the second cross-slide 3. FIG. A first tool receptacle P1 for a first tool and a second tool receptacle P2 for a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com