Front axle tooling clamp

A tooling fixture and front axle technology, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of complex structure of front axle positioning tooling, hidden dangers of personal safety of operators, and inability to ensure assembly accuracy, etc., achieving simple structure and low cost , the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

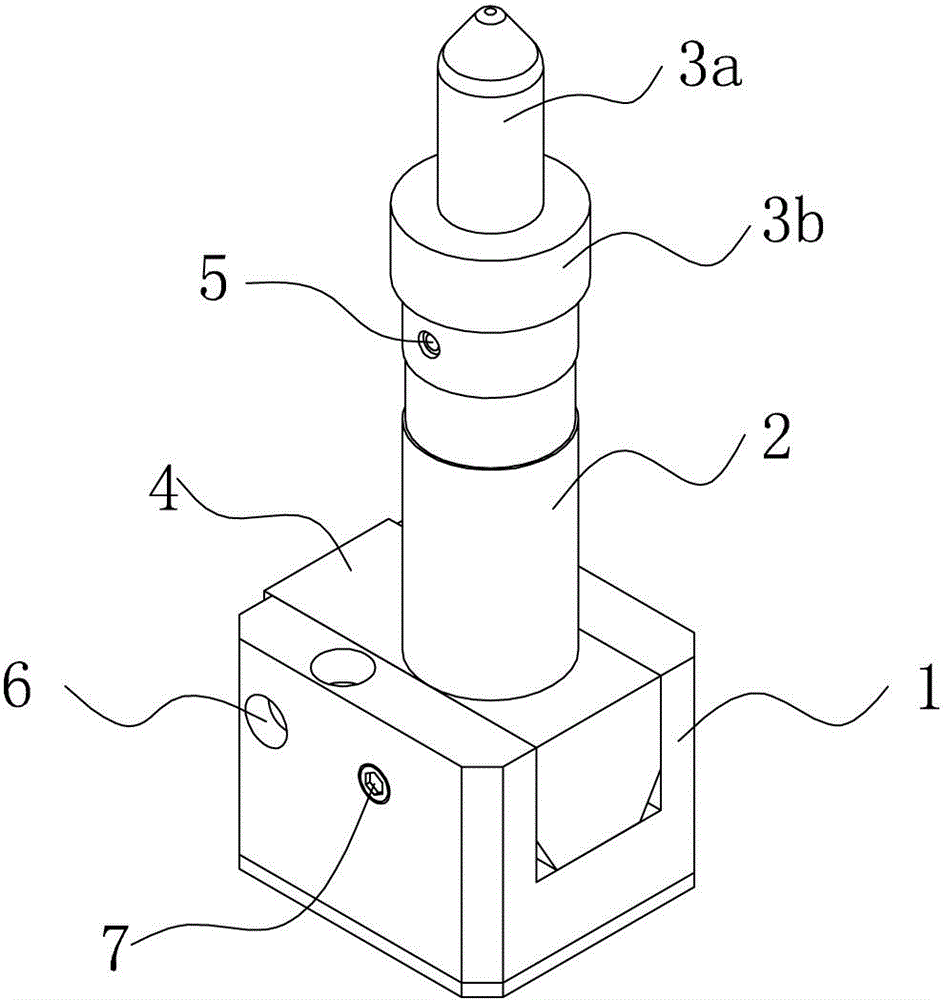

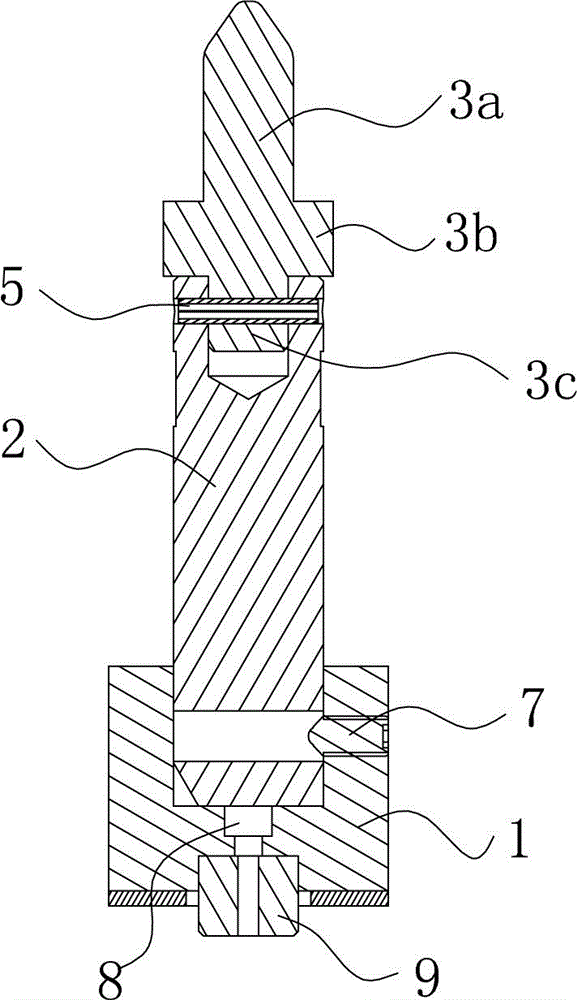

[0013] Such as Figure 1-2 As shown, the front axle tooling fixture according to the embodiment of the present invention mainly includes a base 1, a support rod 2 and a support block. The base 1-2 is a square body, a square groove is provided in the middle of the base 1, and the support rod 2 One end of the connector block 4 is inserted into the square groove, and a spring pin 7 and a rotating shaft 6 are provided at the fitting position between the connector block 4 and the base 1. The support block includes a support portion 3a and a limit portion 3b And the plug-in portion 3c, the plug-in portion 3c is plugged into the top end of the support rod 2, a positioning pin 5 is provided where the plug-in portion 3c and the support rod 2 fit, and the limit portion 3b is clamped on the top surface of the support rod 2. , The supporting portion 3a is in the shape of a pin, a countersunk hole is arranged in the square groove, and the base is connected with a positioning column 9 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com