Filtering element cylinder locking tool

A filter cartridge and tool technology, applied in the field of filter cartridge locking tools, can solve the problems of labor, limited space, inconvenient operation, etc., and achieve the effects of simple structure, convenient locking, and overcoming limited space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

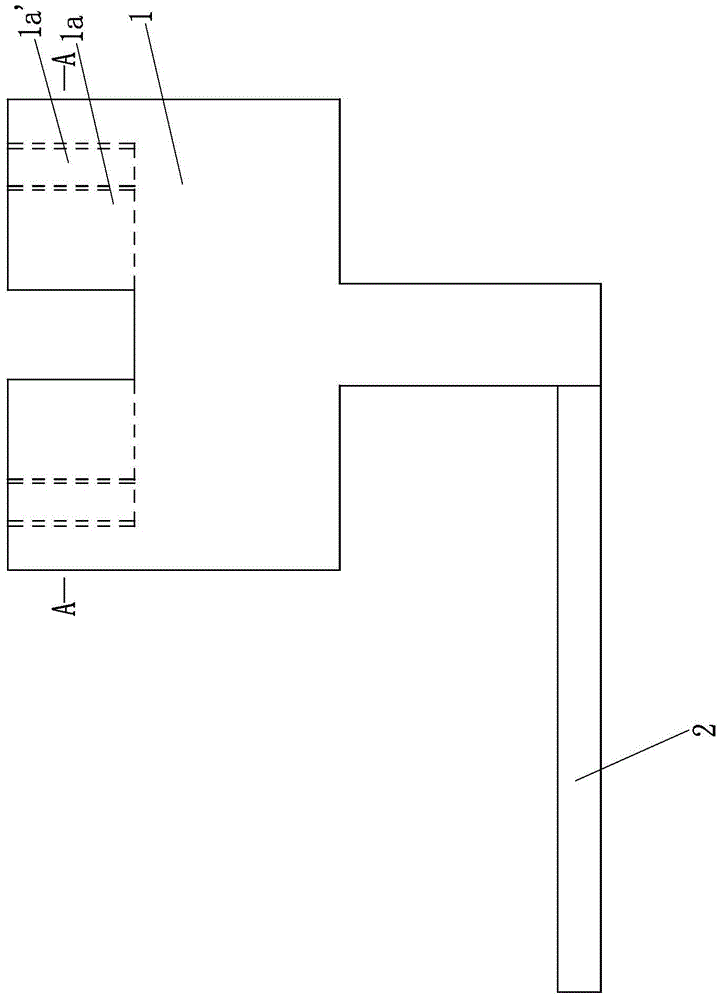

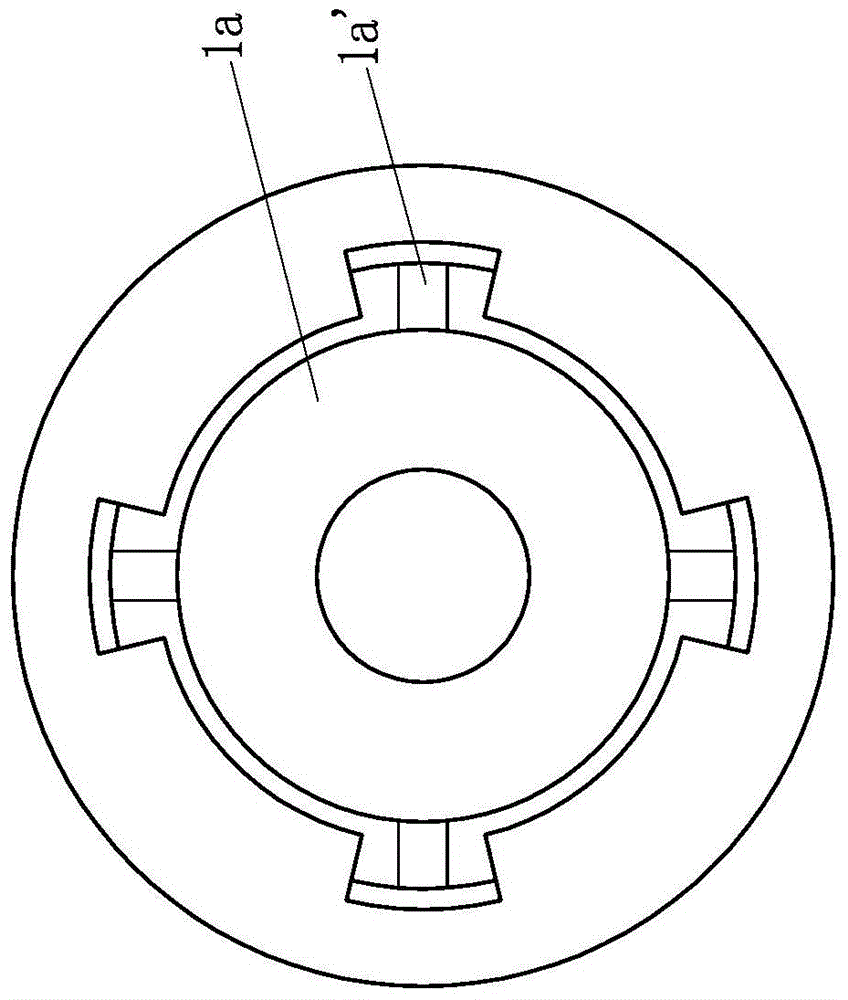

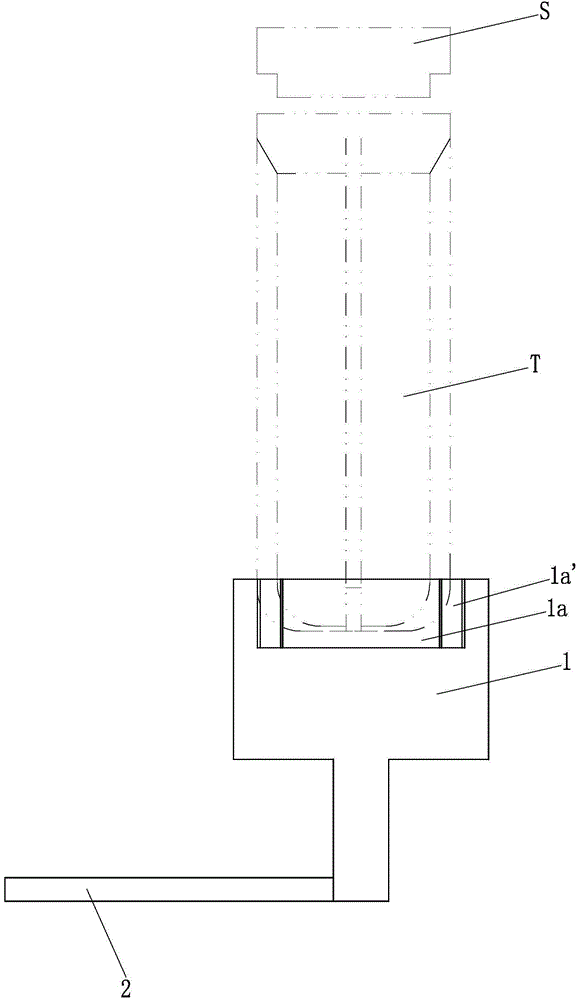

[0016] Such as figure 1 , 2 And shown in 3, a kind of filter cylinder body locking tool, this locking tool is made of tool body 1 and rotating rod 2. Among them, the tool body 1 is a two-stage stepped shaft structure with a large upper part and a smaller lower part. A rotating rod 2 is fixed on the bottom surface of the small diameter part, and the rotating rod 2 is perpendicular to the axis line of the tool body 1. Moreover, the rotating rod The distance from the top surface of 2 to the top surface of the tool body 1 is 7-10mm, and can be further preferably 8, 9, 10mm, and the length of the rotating rod 2 is 8-15mm, and can be adjusted at 9, 10, 11mm according to actual needs. , 12, 13 and 14mm are preferred. In addition, the tool body 1 and the rotating rod 2 are integrally formed by injection molding. Of course, the two can also be selected as metal par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com