Lifting cab and tunnel boring machine

A tunnel boring machine and cab technology, applied in the field of construction machinery, can solve the problems of large installation distance of components, unfavorable control cost, inconvenient maintenance, etc., and achieve the effect of reducing equipment cost, lowering lifting height, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

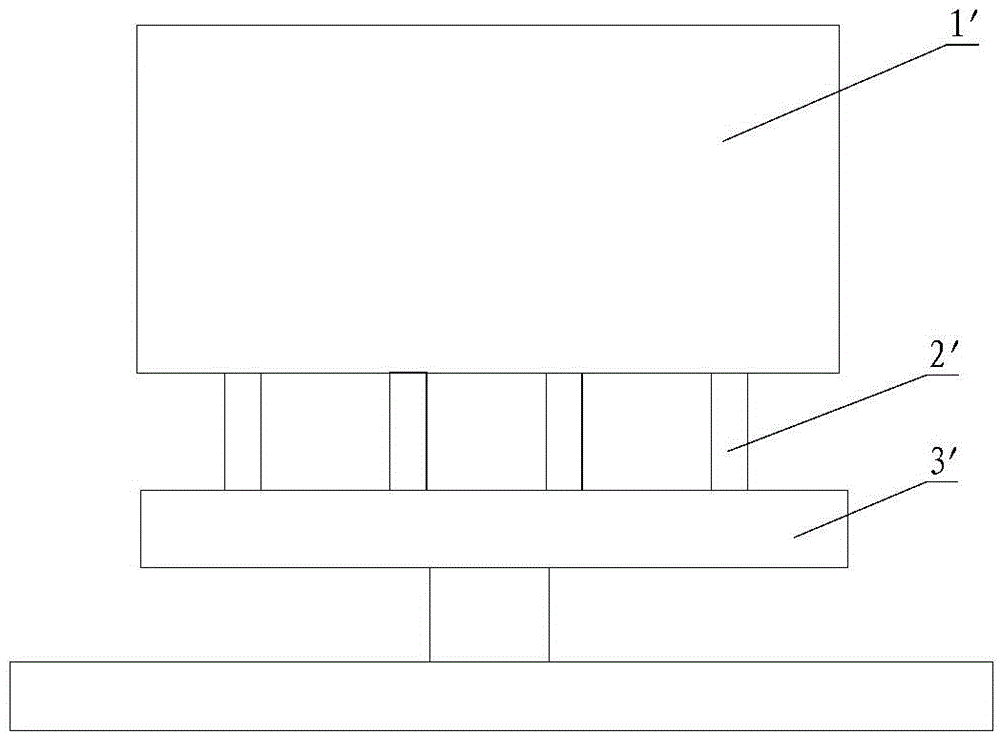

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. Various preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

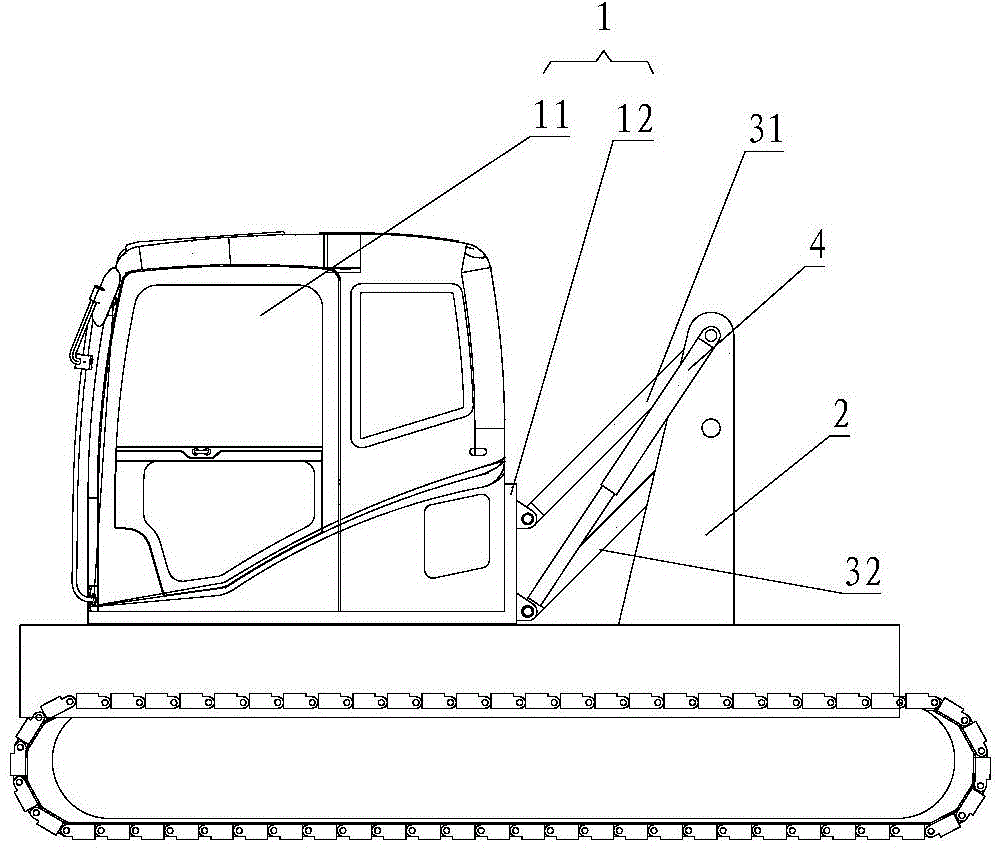

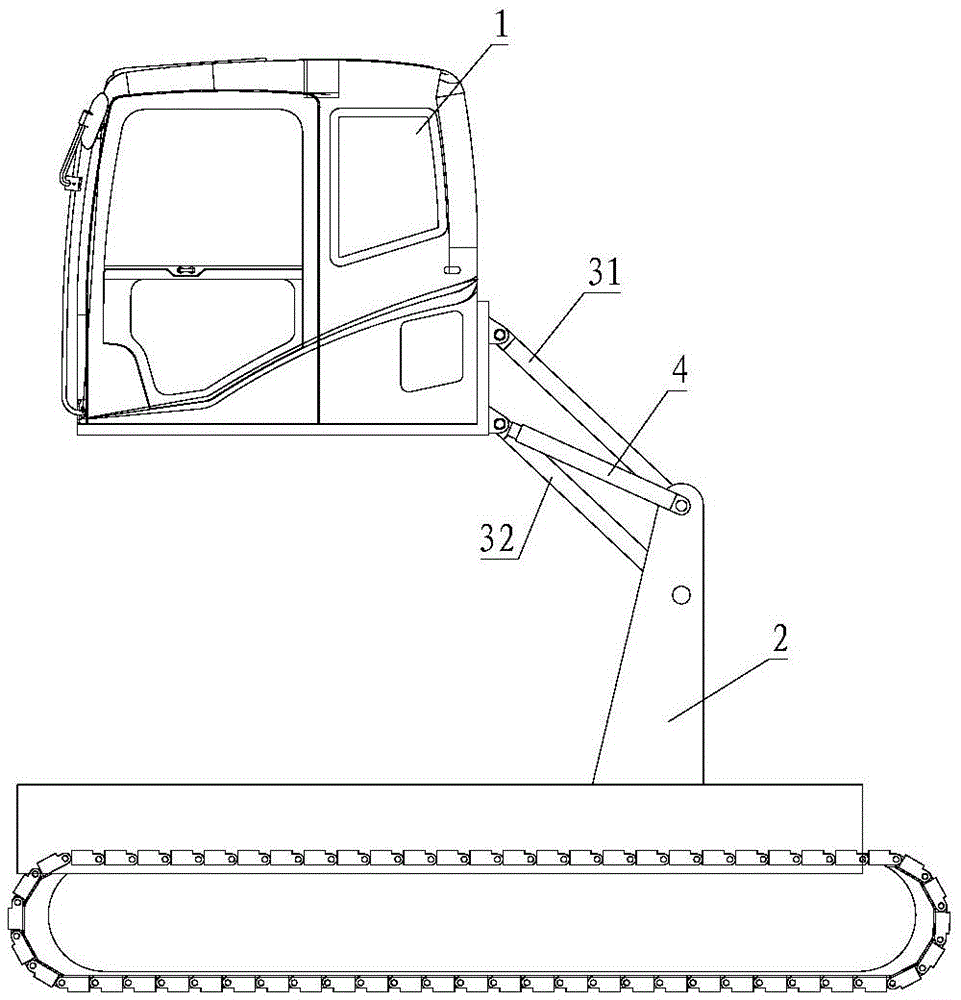

[0029] See figure 2 and image 3 , which shows the structure of the lifting cab provided by the embodiment of the present invention. The elevating cab provided in this embodiment is used for tunnel boring machines, and the elevating cab includes:

[0030] Cab 1;

[0031] The fixed bracket 2 is fixedly arranged at the rear of the cab 1; the rear mentioned in this application is the orientation close to the back of the cab 1;

[0032] The connecting rod assembly at least comprises a first connecting rod 31 and a second connecting rod 32 arranged in parallel, and the first ends of the first connecting rod 31 and the second connecting rod 32 are connected with the cab 1; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com