Lifting mechanism for cantilever-type mechanical garage

A technology for a mechanical garage and a lifting mechanism, which is applied in the field of lifting mechanisms, can solve the problems of fatigue fracture of steel cables, complex equipment structure, damage and fracture, etc., and achieves the effects of convenient operation, safe and reliable structure, and reduction of the number of oil cylinders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

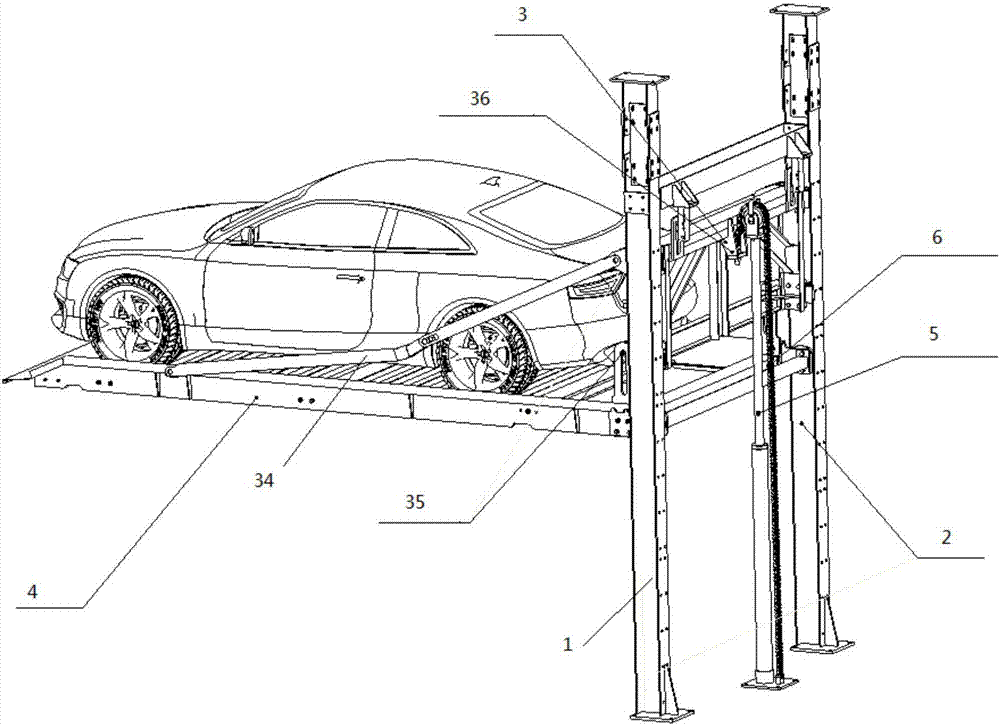

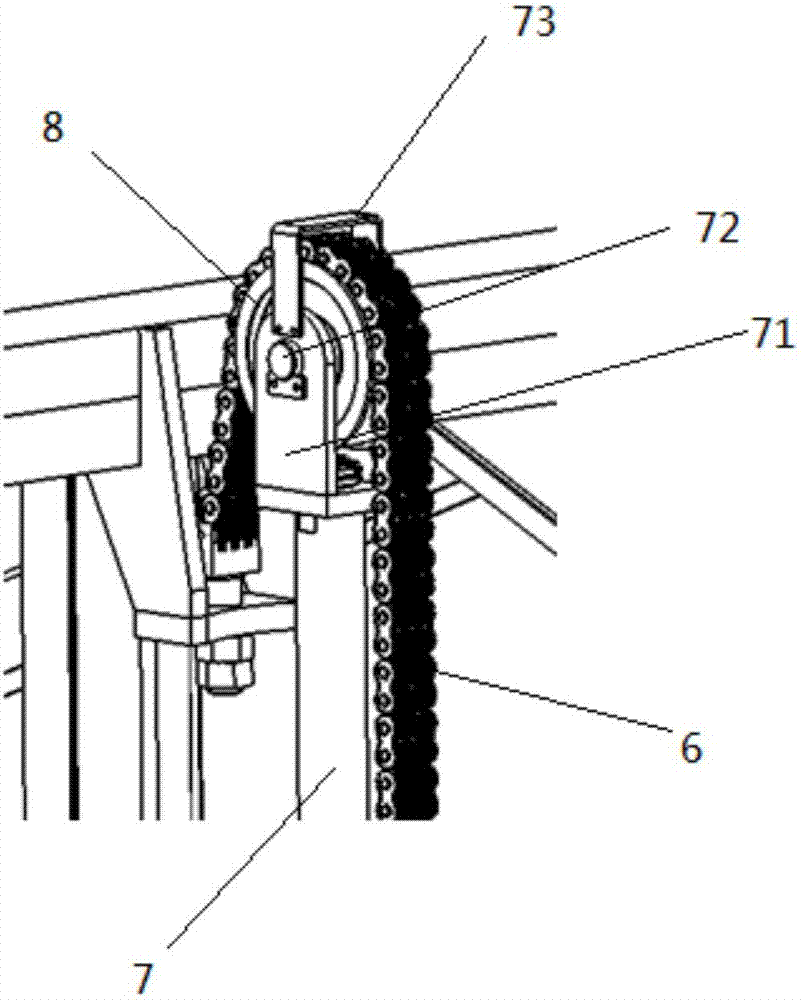

[0025] Such as figure 1 As shown, a lifting mechanism for a cantilever type mechanical garage includes a main column 1 and an auxiliary column 2. The main column 1 and the auxiliary column 2 are connected to a lifting car plate 4 through a lifting frame 3. The main column 1 and the auxiliary column 2 are also provided with a two-way oil cylinder 5 and a chain 6, the two-way oil cylinder 5 is fixed at the center between the main column 1 and the auxiliary column 2, and a push rod 7 moving up and down is provided on the two-way oil cylinder 5 The push rod 7 top is provided with a U-shaped frame 71, the U-shaped frame 71 is provided with a rotating shaft 72, the roller 8 is fixed on the push rod 7 top by the rotating shaft 72, and the U-shaped frame 73 is also inverted at the U-shaped frame 71 top. Such as figure 2 shown.

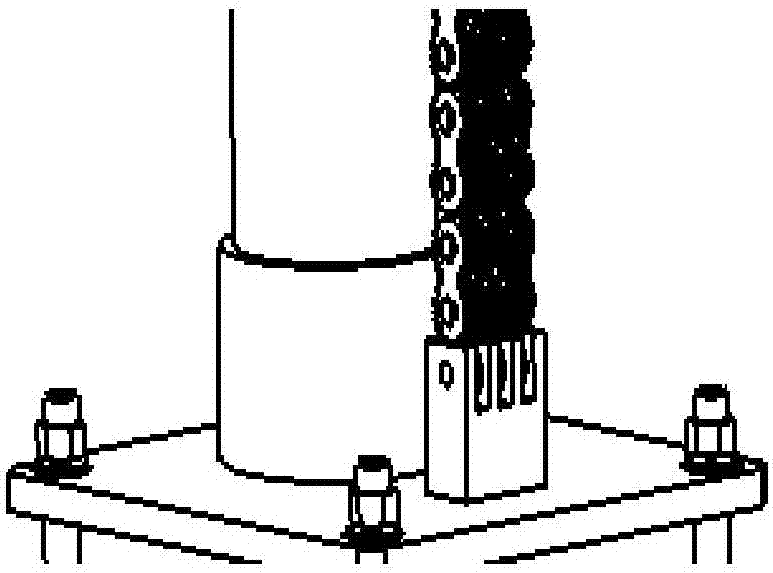

[0026] Described chain 6 one ends are fixed on the two-way oil cylinder 5 bases (as image 3 shown), the other end is connected to the lifting frame 3 aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com