Dustbin

A technology of waste bins and boxes, which is applied in the direction of trash cans, garbage collection, household appliances, etc., can solve the problems of falling into the gap, the push plate cannot be returned normally, and cannot be used normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

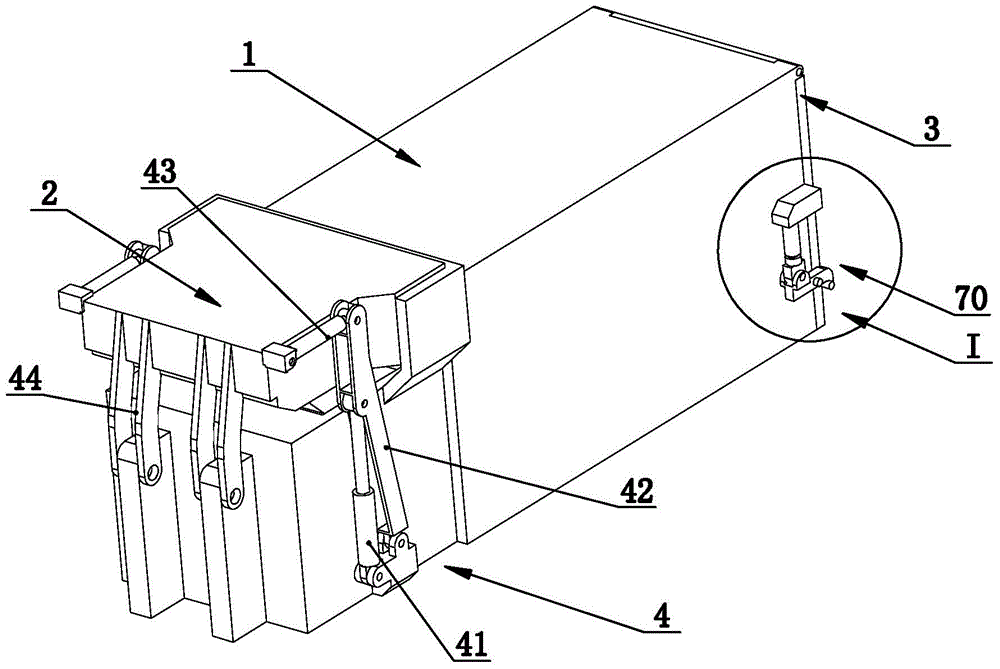

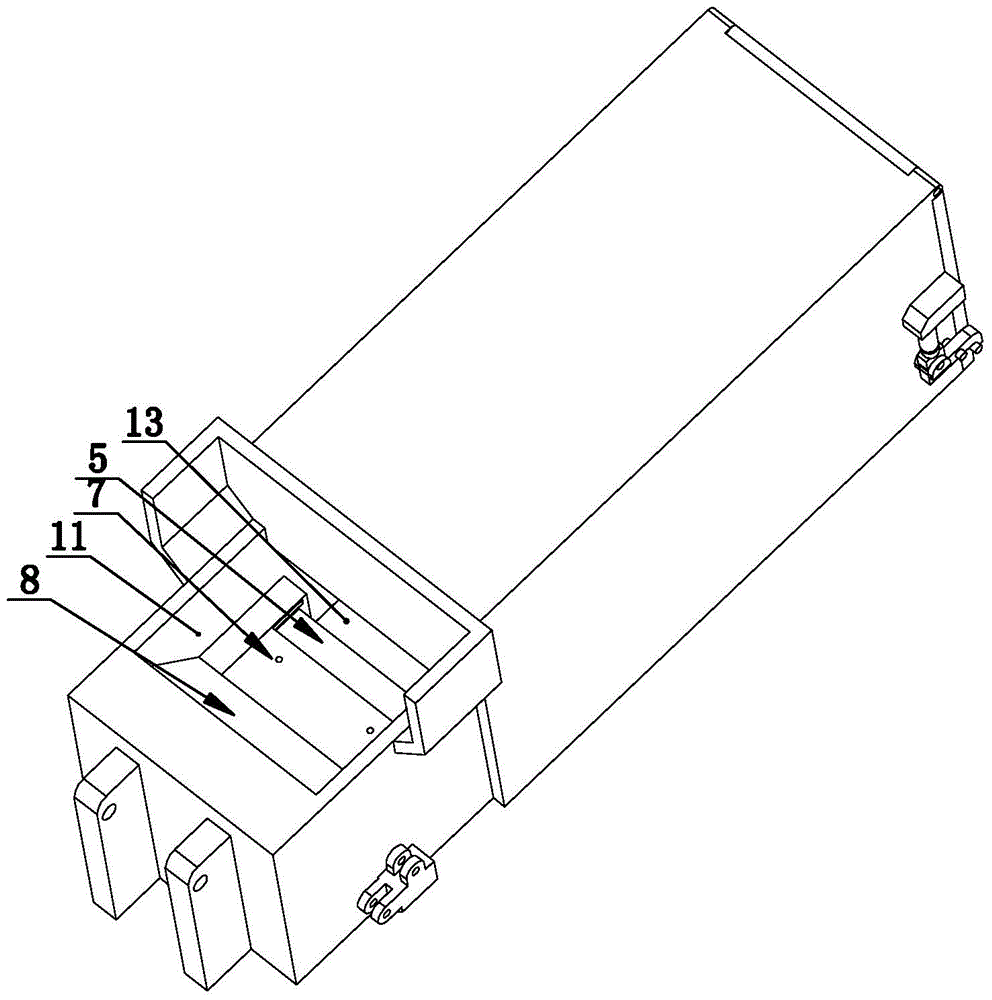

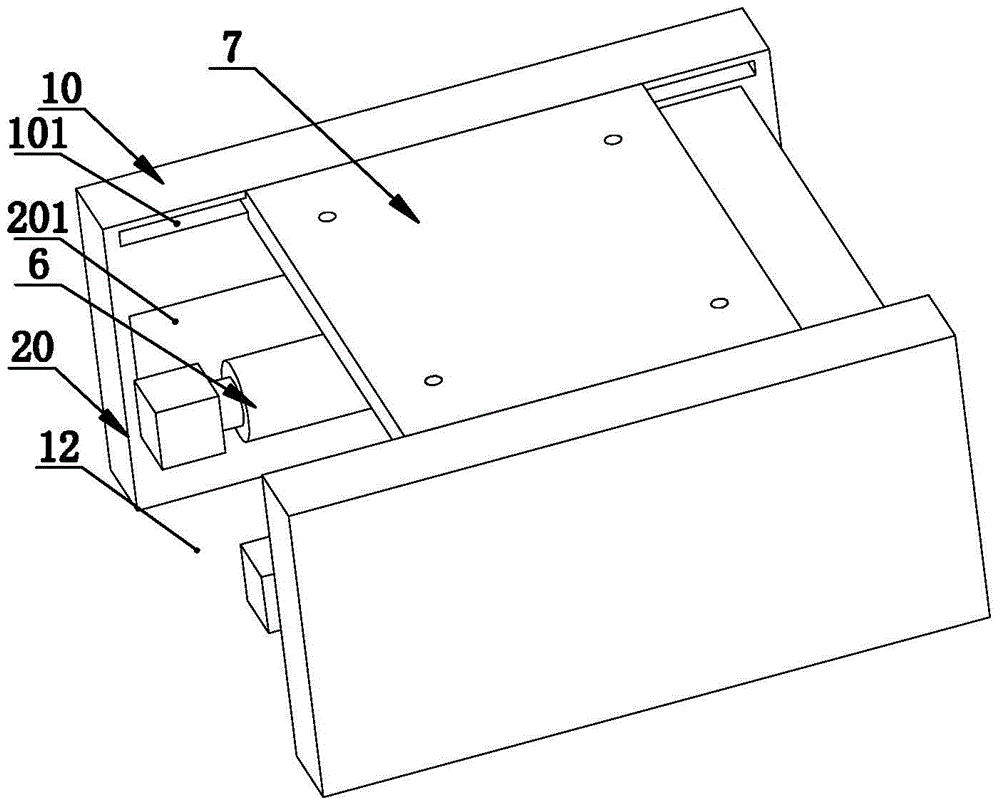

[0022] like Figure 1-6 As shown, a garbage box includes a box body 1, a shovel plate 2 is arranged on the front side of the box body 1, a feeding port 11 is arranged above the box body 1, and a rear side of the box body 1 is provided with a shovel plate 2. The rear door 3, the box body 1 is provided with a turning mechanism 4 for turning the shovel plate 2, and the box body 1 is provided with a working cavity 12 and a storage cavity 13. The working cavity 12 is located on the front side of the storage cavity 13, and the working cavity 12 There is a push plate 5 and a first cylinder 6 for pushing the push plate 5 to expand and contract in the front and rear directions. A baffle plate 7 is arranged above the push plate 5. The baffle plate 7 is slidingly matched with the box body 1 along the front and rear directions. The upper end surface of the push plate 5 is provided with a transmission block 51, and the lower end surface of the baffle plate 7 is provided with a chute 71 alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com