Bobbin-conveniently-loaded stationary type spinning thread winding machine

A winding machine, fixed technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of rising production equipment costs, stop operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Combine below Figure 1-6 The present invention will be described in detail.

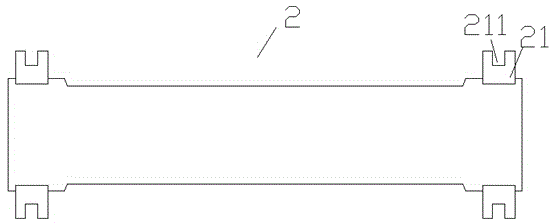

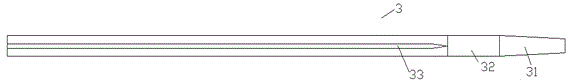

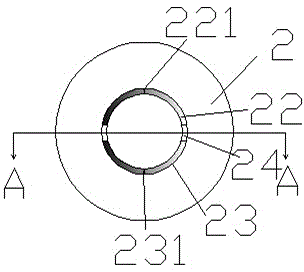

[0026] A stationary textile winding machine that is convenient for loading bobbins, comprising a cantilever main shaft 3, a drive motor 4, a bobbin 2, a bobbin loading and unloading manipulator 6, a fixing device 7 and a wire receiver 5, wherein the cantilever main shaft 3 is Its left end is power-connected with the drive motor 4, and the right end of the cantilever main shaft 3 is a free end; the bobbin loading and unloading manipulator (6) is set on the fixing device (7); the bobbin 2 is provided with an axial Extended central through hole, the cantilever main shaft 3 can pass through the central through hole so as to be able to drive the bobbin 2 installed thereon, the silk thread receiver 5 is used to receive the silk thread 1 from the twisting machine, and can be relatively The bobbin 2 installed on the cantilever main shaft 3 moves in a direction parallel to the axial direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com