Spinning thread winding machine provided with multiple strip-shaped keys and multiple key grooves

A winding machine and keyway technology, applied in the field of textile winding machines, can solve problems such as work stoppage and production equipment cost rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

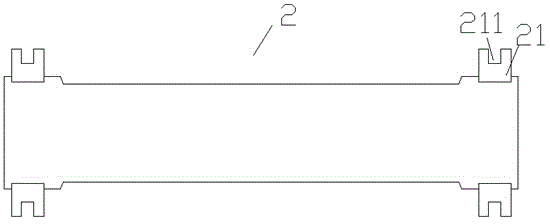

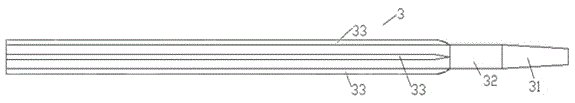

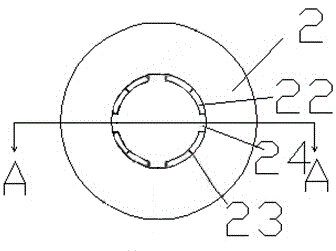

[0024] Combine below Figure 1-6 The present invention will be described in detail.

[0025] A textile winding machine comprising a plurality of keys and a plurality of key slots, comprising a cantilever main shaft 3, a drive motor 4, a bobbin 2, a bobbin loading and unloading manipulator 6 and a wire receiver 5, wherein the cantilever main shaft 3 is in its The left end is power-coupled with the drive motor 4, and the right end of the cantilever main shaft 3 is a free end; the bobbin 2 is provided with an axially extending central through hole, and the cantilever main shaft 3 can pass through the central through hole so as to be able to Driving the bobbin 2 mounted on it, the thread receiver 5 is used to receive the thread 1 from the twisting machine, and can be parallel to the cantilever main shaft with respect to the bobbin 2 installed on the cantilever main shaft 3 3 moves in the axial direction, so that the silk thread can be evenly wound on the bobbin 2;

[0026] A plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com