Hoisting cable automatic connection device for underwater robot

An underwater robot, automatic connection technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve problems such as hidden safety hazards and low efficiency, and achieve the effect of convenient deployment and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

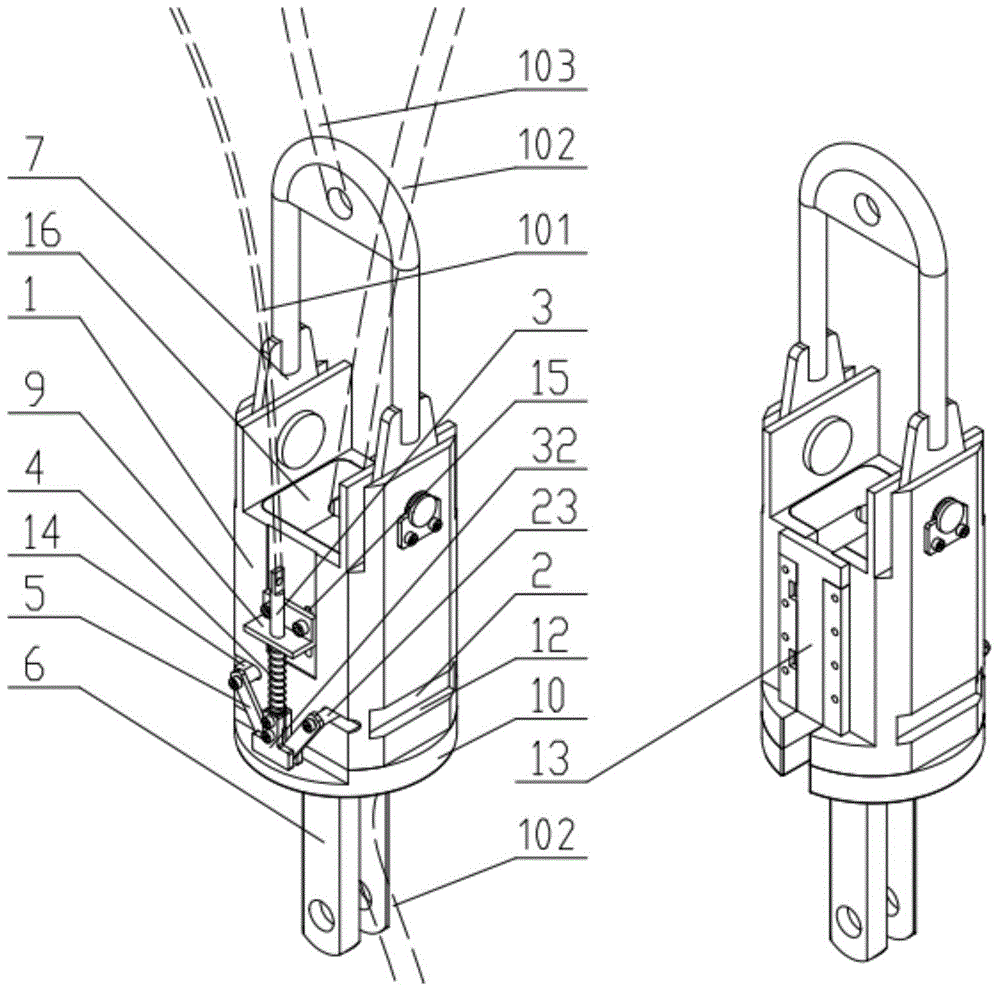

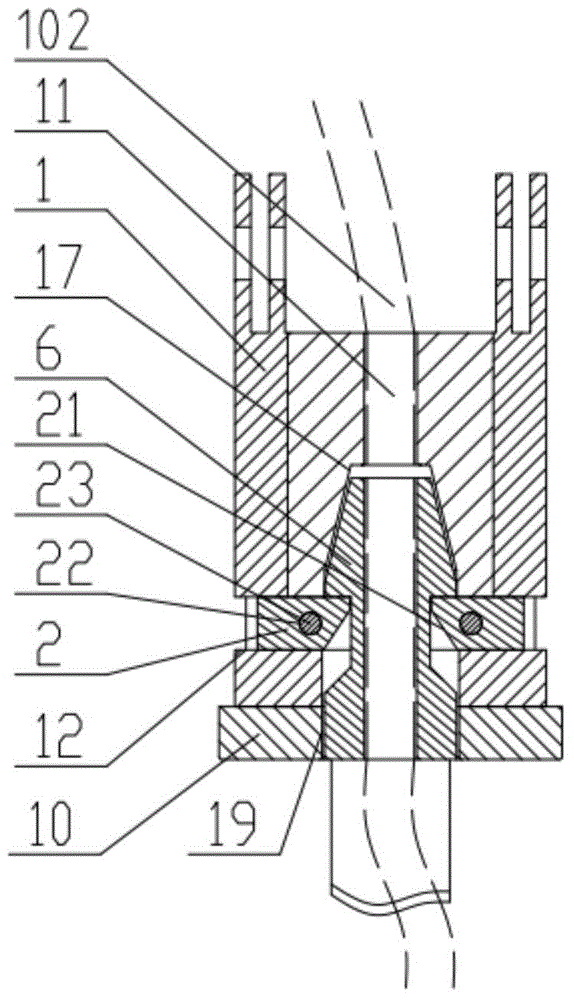

[0023] The invention provides an automatic connection device for lifting cables for an underwater robot to realize automatic mounting and opening of the lifting cables when deploying and recovering the underwater robot. The present invention will be described in further detail below in conjunction with the accompanying drawings.

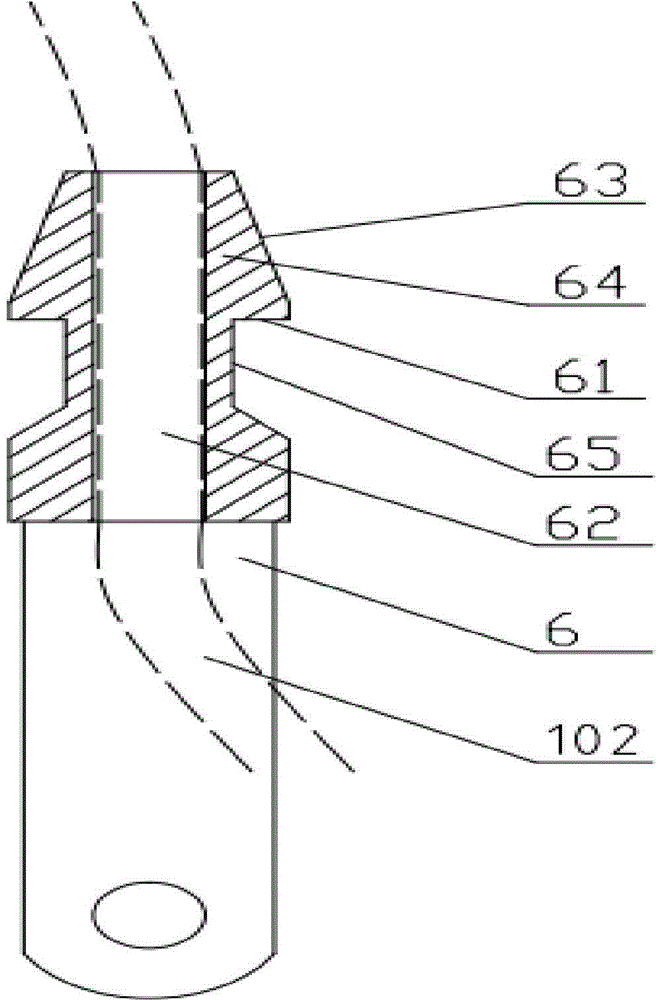

[0024] Such as Figure 1~5 , the present invention includes: base (1), slider (2), pull bolt (3), return spring (4), connecting rod (5), hook device (6), lifting lug device (7), lifting cable (8), spring baffle (9), rubber spacer (10), base door (13), upward limit block (16). The base (1) is provided with an umbilical cable channel (11), and the hook device (6) can also be inserted into the umbilical cable channel (11).

[0025] The upper limit block (16) is used to limit the upward movement position of the hook (6), and usually selects a softer material, such as Teflon. There is a truncated conical hole (17) in the lower part of the upward limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com