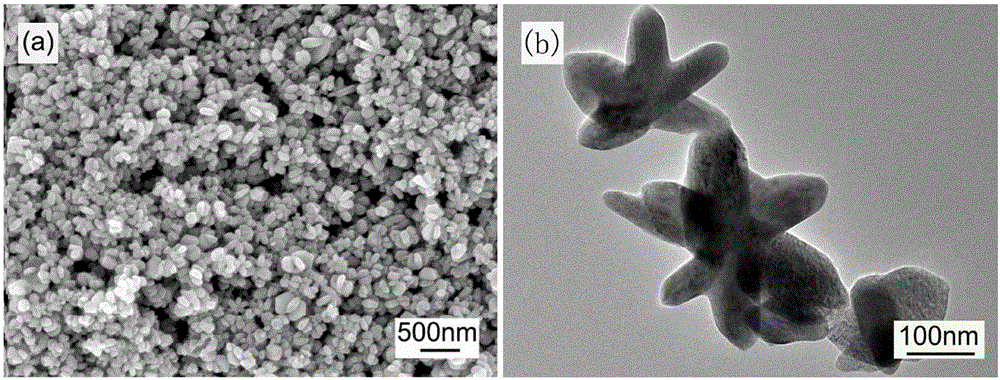

d-phase vanadium dioxide nano-star powder and preparation method thereof

A vanadium dioxide nano, vanadium dioxide technology, applied in the field of D-phase vanadium dioxide nano star powder and its preparation, can solve the problems of unfavorable application, complex process, etc., and achieve low production cost, difficult to agglomerate, small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

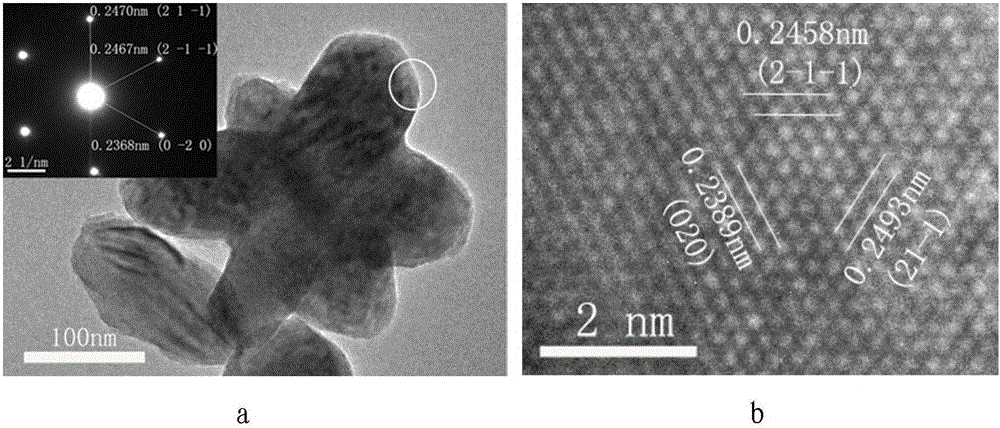

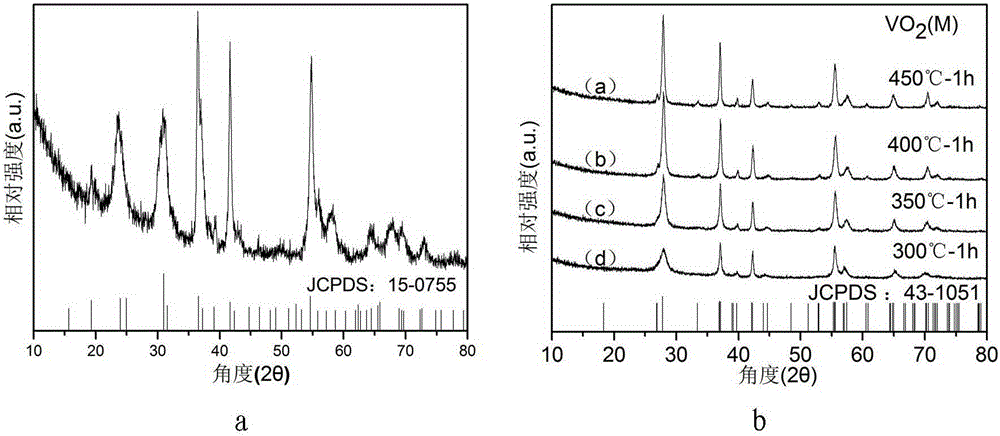

Examples

Embodiment 1

[0033] The concrete steps of preparation are:

[0034] Step 1: First, according to the weight ratio of 0.05:5, ammonium metavanadate was dissolved in deionized water and stirred for 0.5 h to obtain ammonium metavanadate aqueous solution. Then, 80wt% formic acid solution was added dropwise into the ammonium metavanadate aqueous solution under stirring to obtain a mixed solution with a pH value of 3.

[0035] In step 2, the mixed solution is placed in an airtight state, and reacted at 180° C. for 3 days to obtain a reaction solution. Then the reaction solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the rotational speed and time of centrifugation are respectively 5000r / min and 10min, and the washing process is to use deionized water and ethanol to The separated solids were washed alternately for 3 times. During the cleaning, the solids were separated by centrifugation. The temperatu...

Embodiment 2

[0037] The concrete steps of preparation are:

[0038]Step 1: First, according to the weight ratio of 0.055:5, ammonium metavanadate was dissolved in deionized water and stirred for 0.6 h to obtain an ammonium metavanadate aqueous solution. Then, 83wt% formic acid solution was added dropwise into the ammonium metavanadate aqueous solution under stirring to obtain a mixed solution with a pH value of 2.5.

[0039] In step 2, the mixed solution is placed in an airtight state and reacted at 190° C. for 2.5 days to obtain a reaction solution. Then the reaction solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the rotational speed and time of centrifugation are 6000r / min and 9min respectively, and the washing process is to use deionized water and ethanol to The separated solids were washed alternately for 3 times, and the solids were separated by centrifugation during cleaning. The tempe...

Embodiment 3

[0041] The concrete steps of preparation are:

[0042] Step 1: First, according to the weight ratio of 0.06:5, ammonium metavanadate was dissolved in deionized water and stirred for 0.75h to obtain ammonium metavanadate aqueous solution. Then, 85wt% formic acid solution was added dropwise to the ammonium metavanadate aqueous solution under stirring to obtain a mixed solution with a pH value of 2.

[0043] In step 2, the mixed solution is placed in an airtight state, and reacted at 200° C. for 2 days to obtain a reaction solution. Then the reaction solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the rotational speed and time of centrifugation are respectively 7500r / min and 7.5min, and the washing process is to use deionized water and ethanol The separated solid matter was alternately washed 4 times, the solid matter was separated by centrifugation during washing, and the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com