Semi-enclosed wind-shielding structure of high-speed railway segmented trough beam

A technology of high-speed railways and channel beams, applied in construction, protective equipment, etc., can solve problems such as difficulty in ensuring train safety, achieve obvious wind-shielding effects, meet anchoring requirements, and achieve high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in combination with specific embodiments.

[0029] The invention proposes a brand-new high-speed railway wind-shielding structure form, and the high-speed railway sliced channel beam semi-closed wind-shielding structure. For the first time, the concept of combining the beam body with the wind-shielding function and the wind-shielding structure in the core area of the strong wind was proposed, and the groove-shaped beam was applied to the high-speed railway bridge project for the first time. The windshield structure provides a new option.

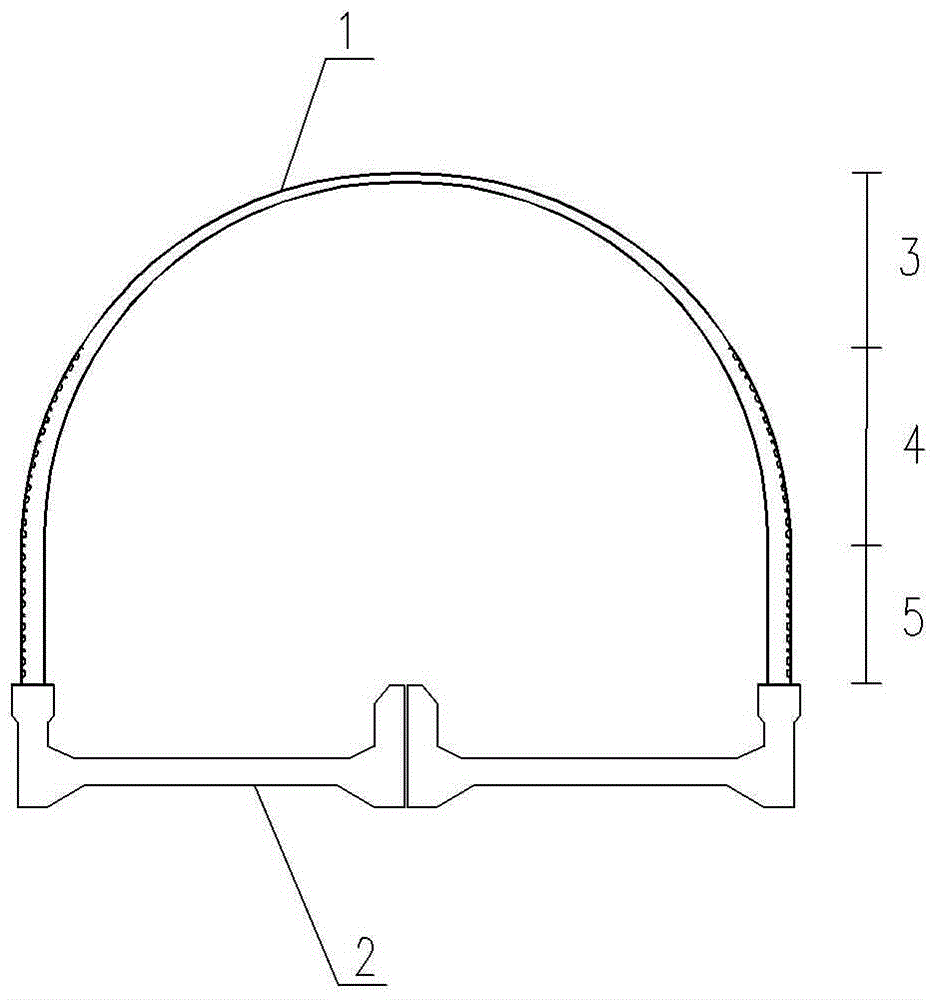

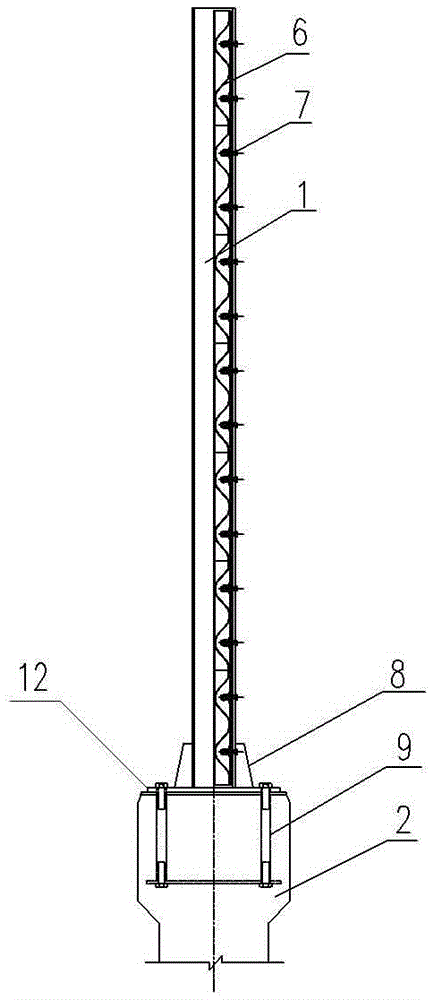

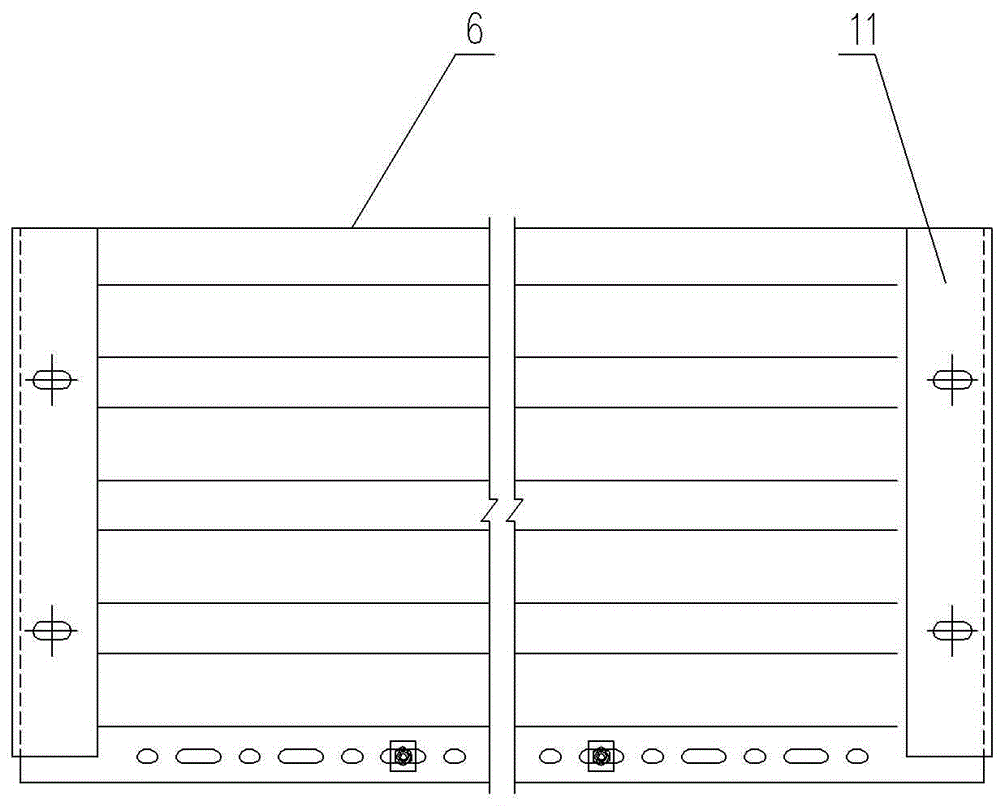

[0030] It involves a semi-closed windshield structure of segmented channel beams for high-speed railways, including multi-channel arches 1 arranged at longitudinal intervals and spanning the webs at the left and right ends of channel beams 2, which are H-shaped steels formed by splicing. The bottom surface of the arch frame 1 is provided with a base plate 12, and the base pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com