Protective components for electric heating pipes for air conditioners

An electric heating tube and air-conditioning technology, which is applied in household heating, household heating, heating methods, etc., can solve the problems of high-temperature combustion, falling or falling off of air-conditioning machines, fire accidents, etc., to achieve extended service life, low cost, The effect of preventing ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing of description, the present invention will be further described.

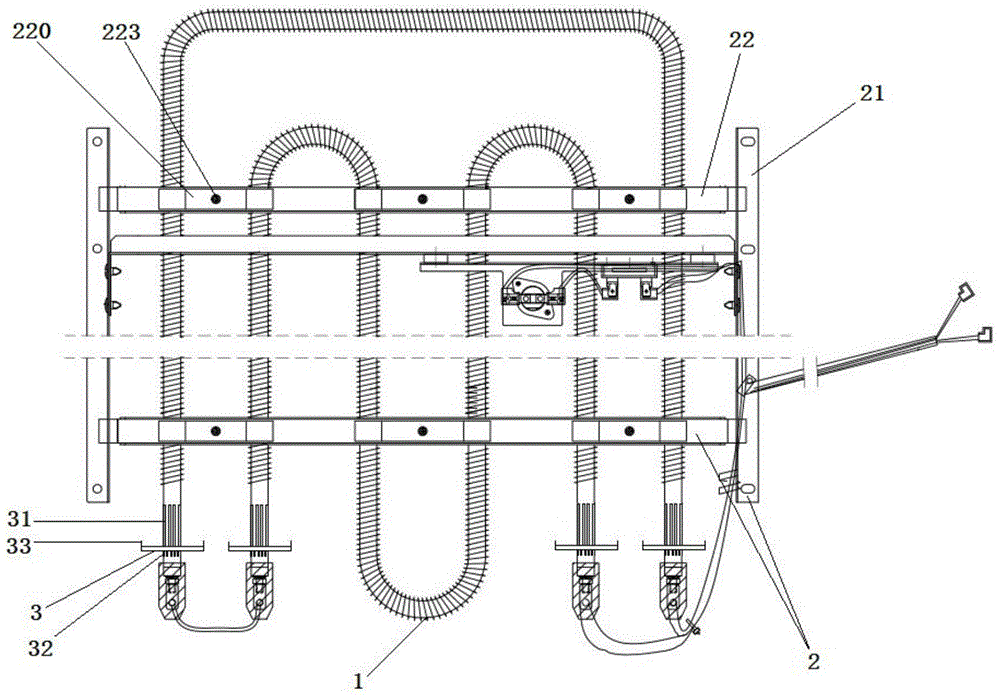

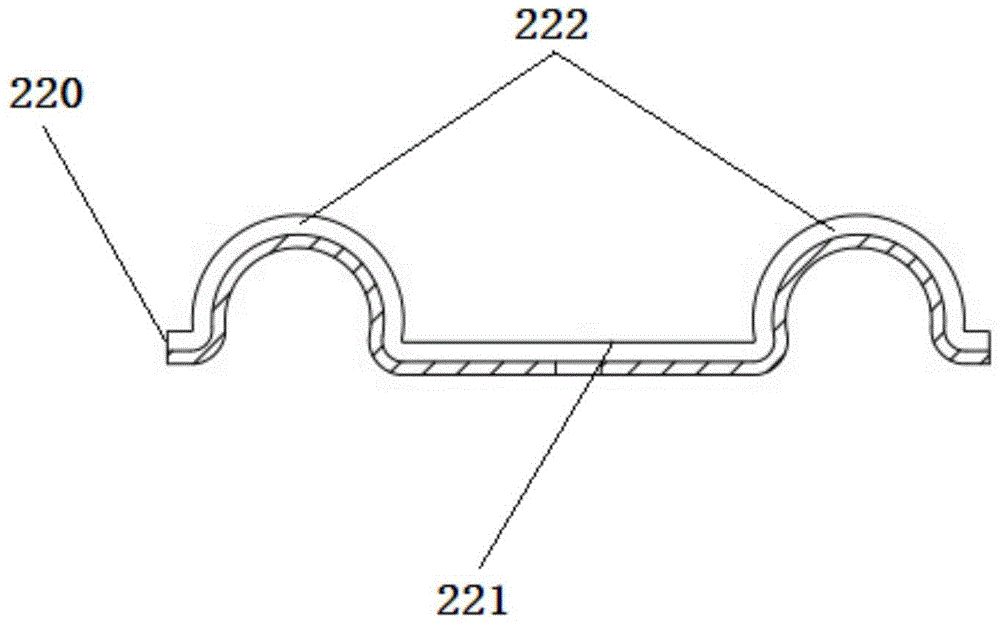

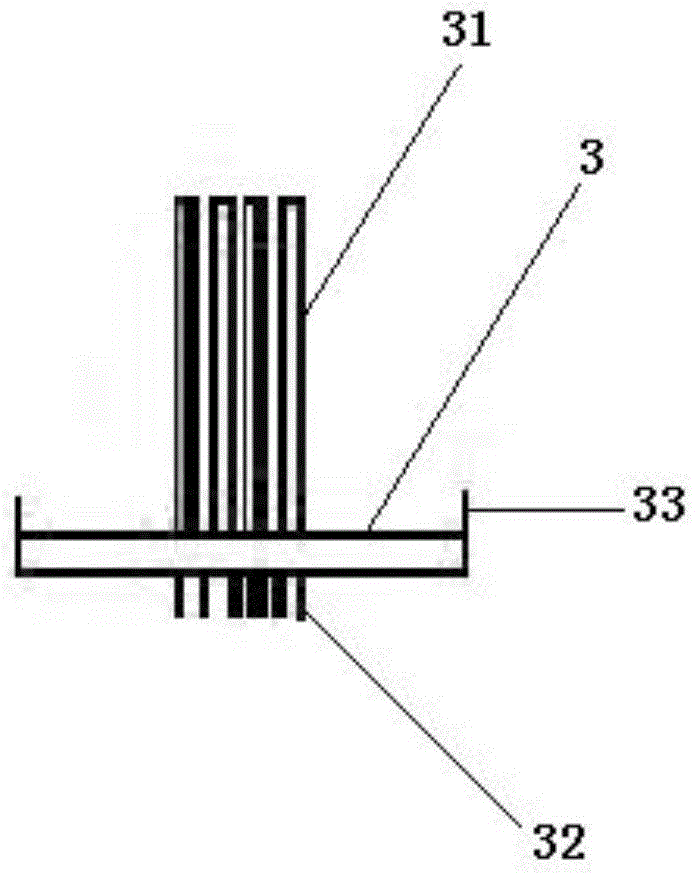

[0026] Such as figure 1 , figure 2 and image 3 As shown, an electric heating tube protection component for air conditioning includes an electric heating tube frame 2 for fixing the electric heating tube 1, and also includes a set of disks for the tube body at the cold zone at the end of the electric heating tube 1 3. The sleeve 3 is used to receive the fragments that fall off from the fusing part of the electric heating tube 1 above the sleeve 3 due to high temperature; The size is matched, the plane of the sleeve 3 is perpendicular to the axial direction of the pipe body in the cold zone; the inner ring edge of the sleeve 3 is provided with grid bars extending upward and clamping the end pipe body of the electric heating tube 1 31. The grid strips 31 extend all the way to the junction of the cold area and the heating area at the end of the electric hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com