Large current common mode filter coil

A common-mode filtering and high-current technology, applied in the direction of transformer/inductor coil/winding/connection, preventing/reducing unnecessary electric/magnetic influence, etc., can solve the problem of poor load capacity, loss of filtering effect, and filter coil Burned and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

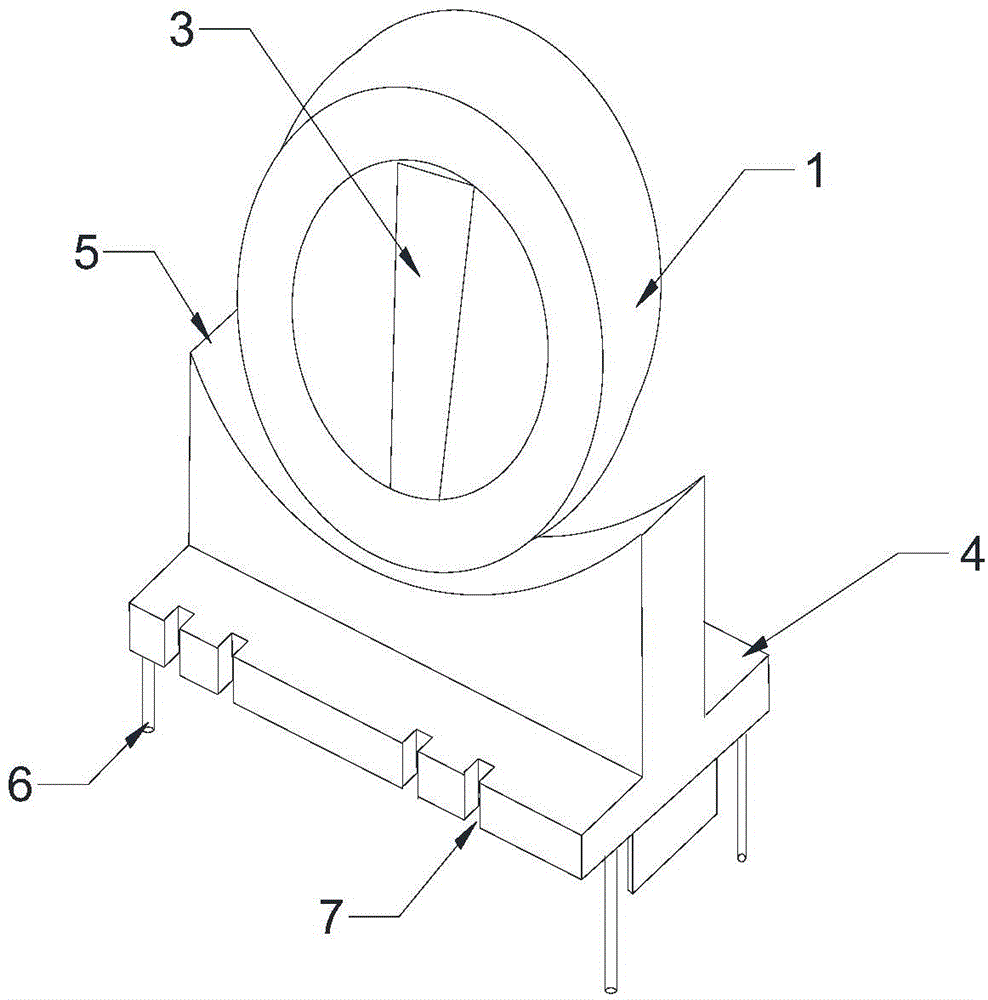

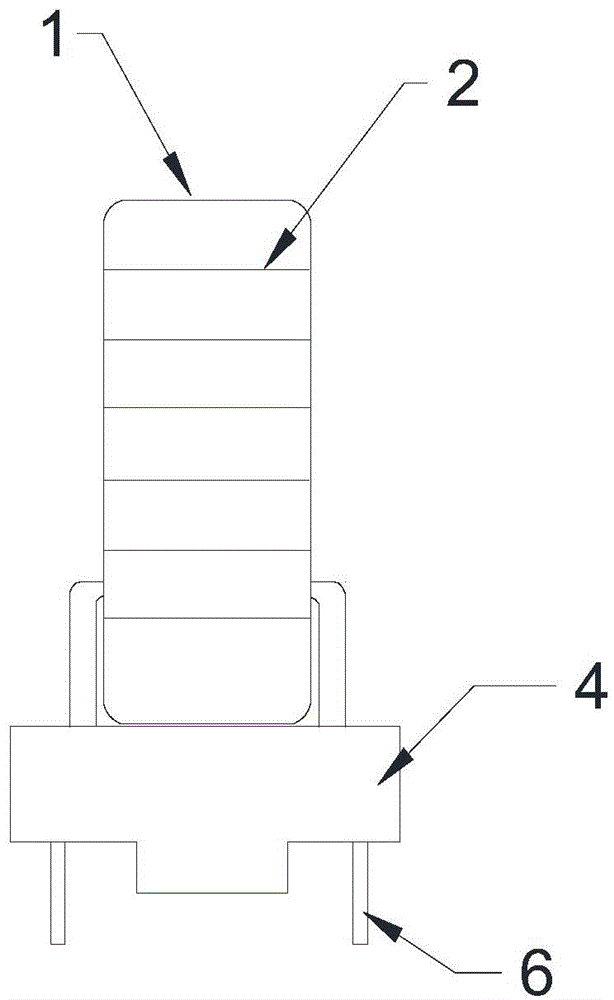

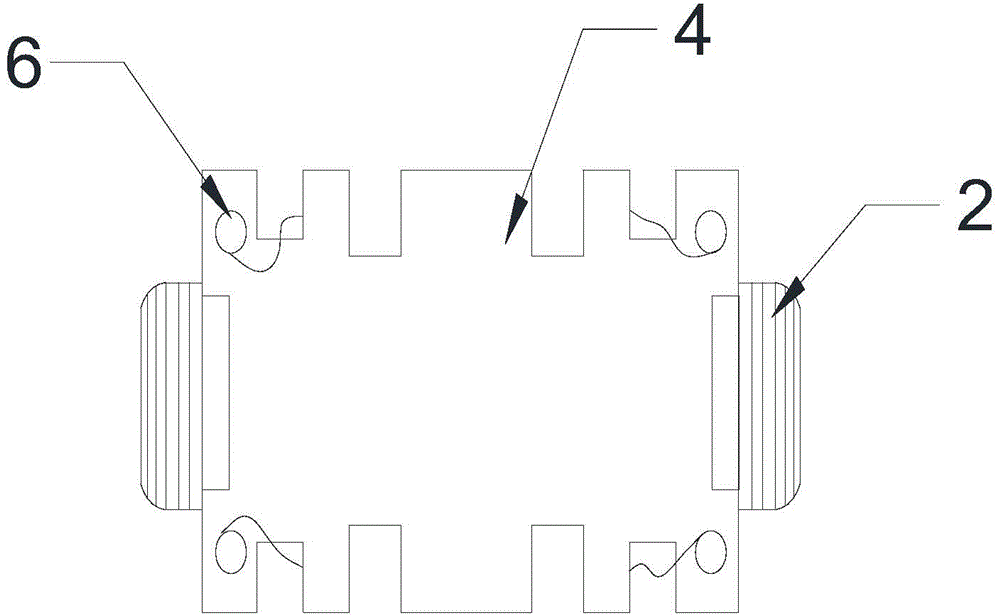

[0014] A high-current common-mode filter coil, comprising a circular magnetic core 1, on which two strands of wires 2 are provided, and the two strands of wires 2 are separated by an insulating plate 3, and also includes a base 4, so that The upper surface of the base is provided with a bracket 5 with an arc surface, and the four apex positions of the lower surface of the base 4 are provided with stitches 6, and the two ends of the wire are connected to the connecting line parallel to the axial line of the circular magnetic core. On the two pins of the base, there is also a guide groove 7 on one side of the base parallel to the radial plane of the circular magnetic core.

[0015] The material of the insulating spacer is an epoxy spacer. On the one hand, the epoxy spacer plays an insulating role to prevent short circuits between two st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com