Patents

Literature

31results about How to "Increased current carrying capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

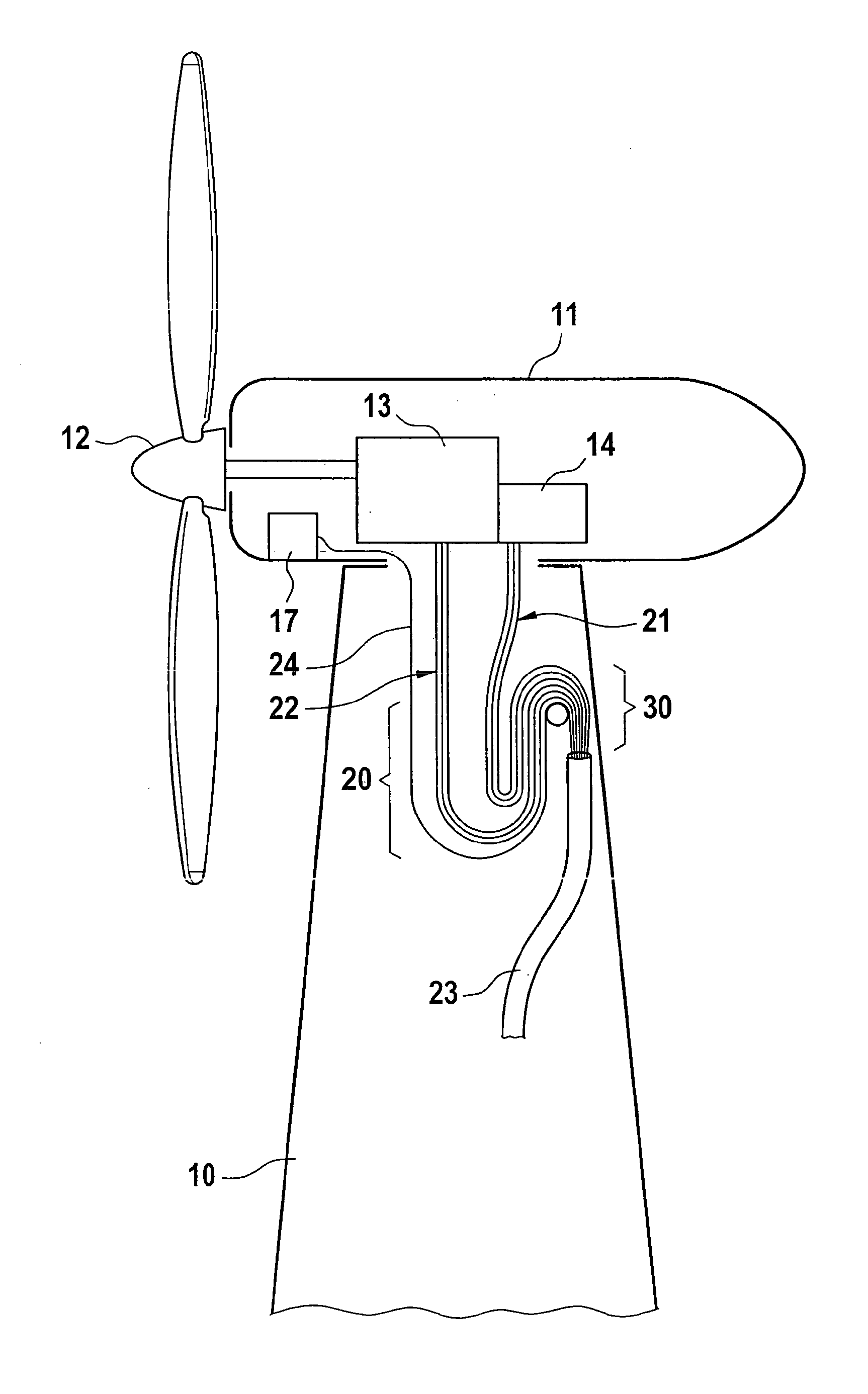

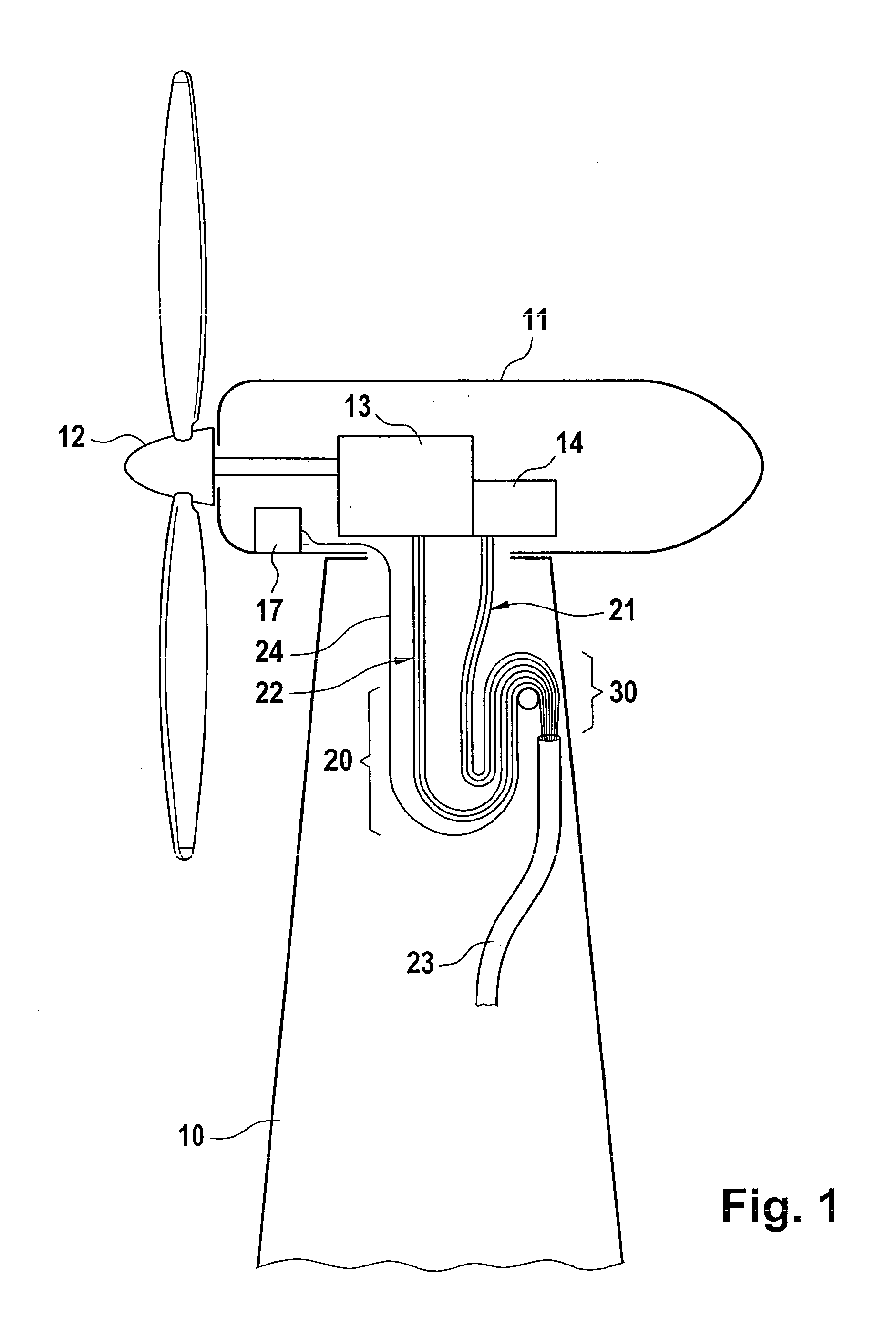

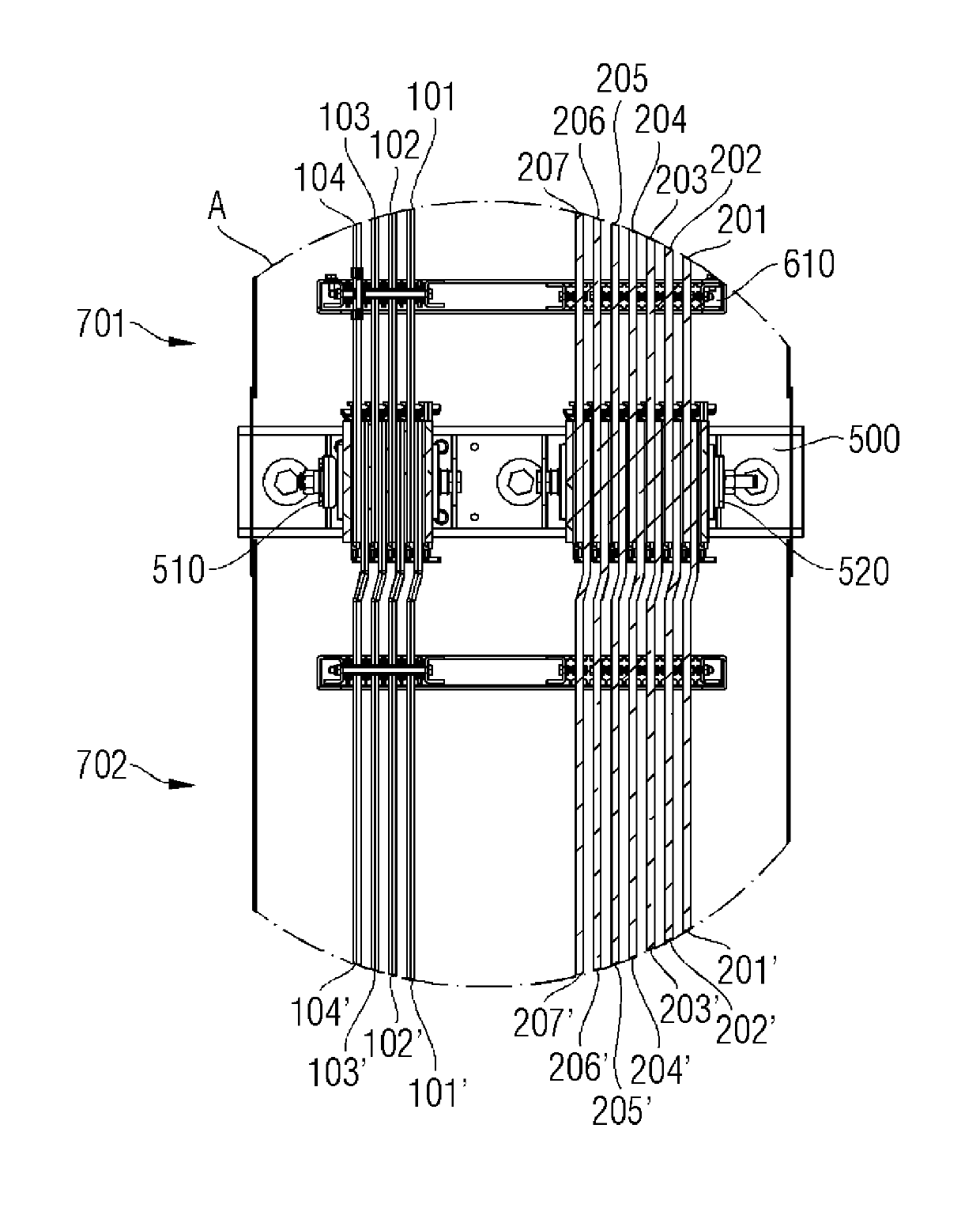

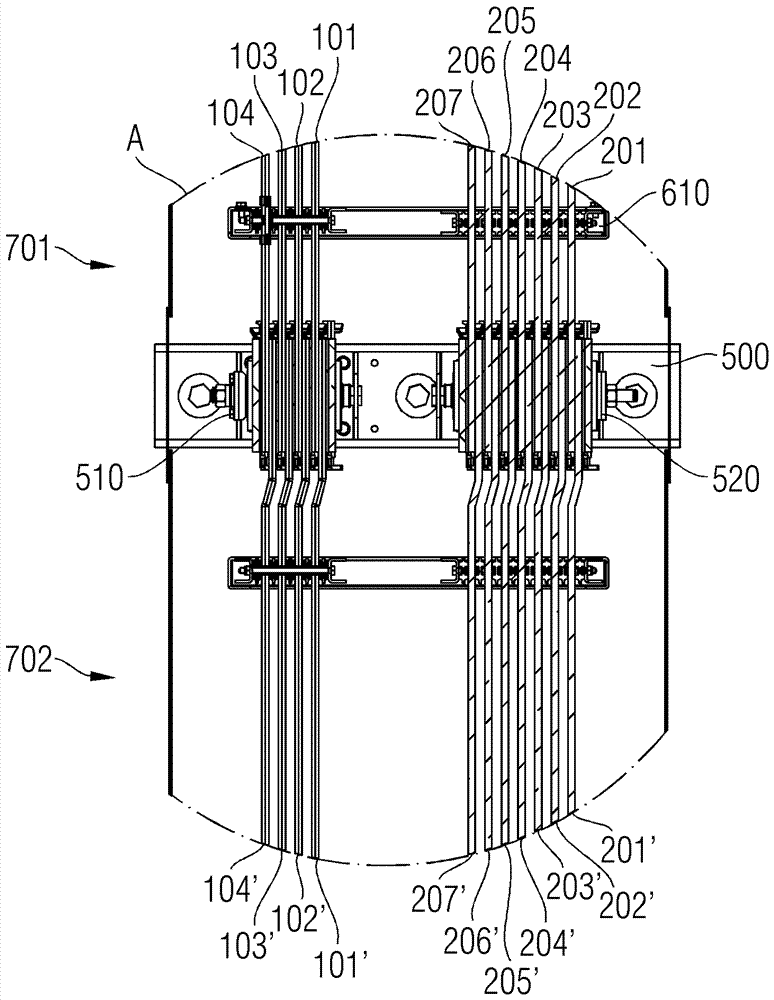

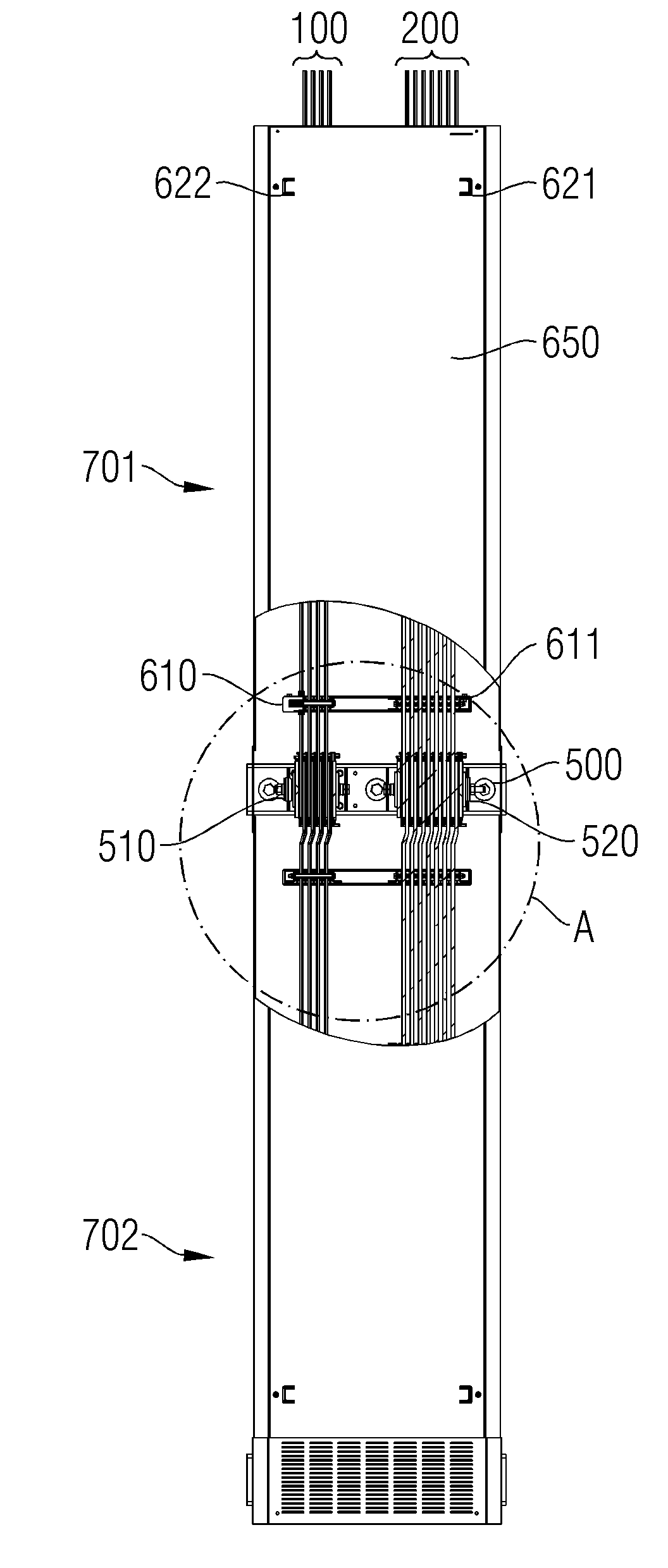

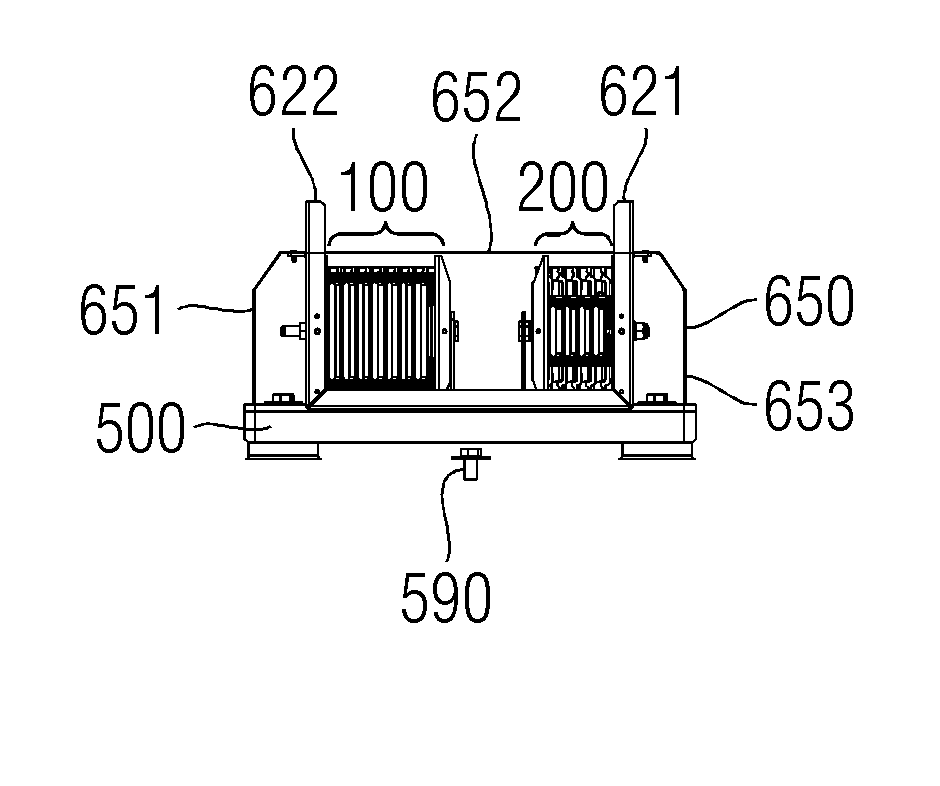

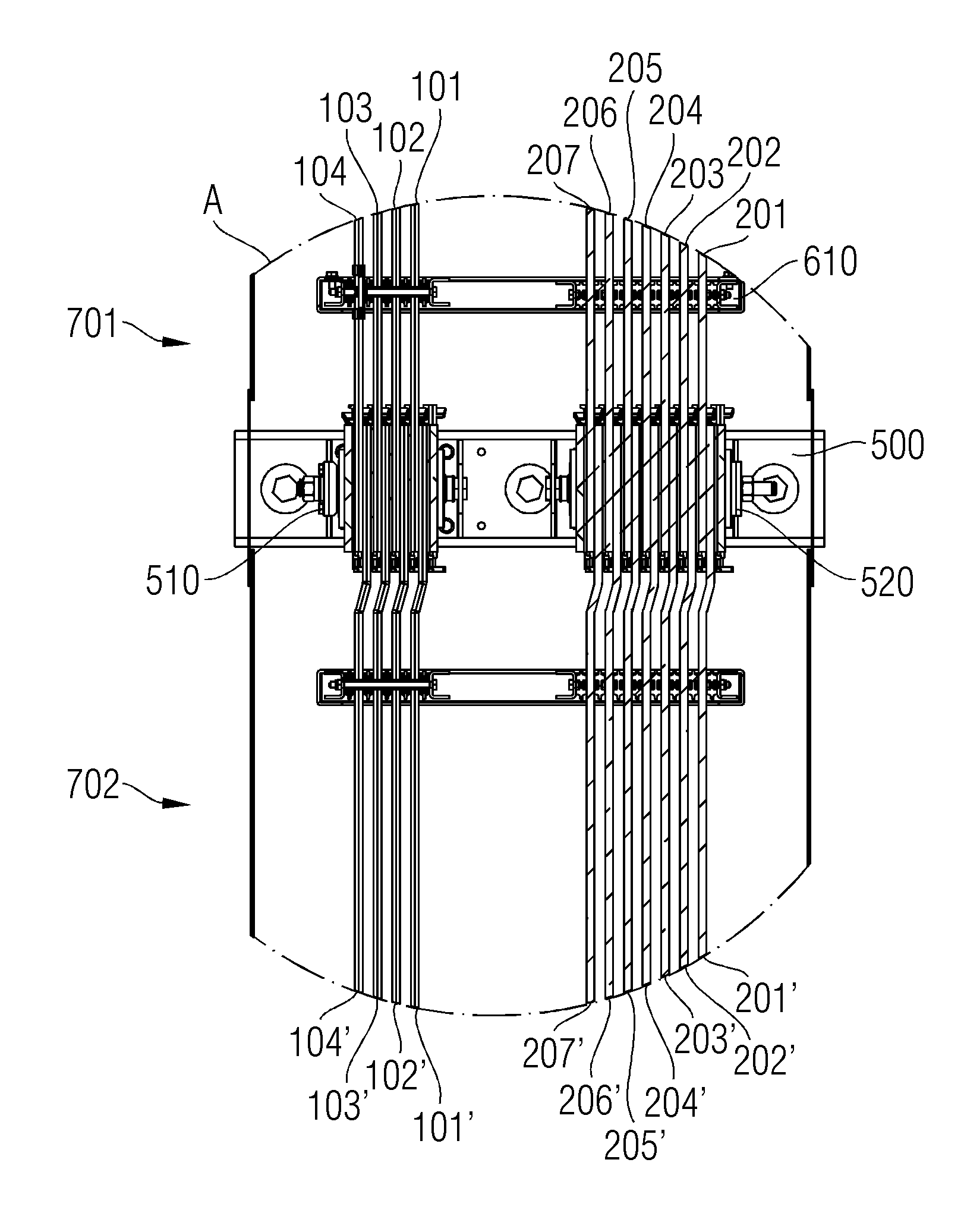

Wind energy plant having a twistable nacelle cable guide

ActiveUS20120006578A1Maintain positionRisk minimizationMachines/enginesCable junctionsNacelleAzimuth direction

A wind energy installation includes a tower and a nacelle arranged at the top of the tower such that it can swivel in the azimuth direction. The installation also includes a plurality of cables which are guided via a loop from the tower into the nacelle, the cables being held at a distance from one another in the loop by means of rotationally fixed and loose holders. The holders each have receptacles for attachment of the cables with a predetermined circumferential separation. The holders include a lower rotationally fixed guide ring and an aligning upper loose guide ring. A loop guide is formed such that the loop is subdivided by means of the rotationally fixed lower guide ring into a curved untwisted area and an extended twisted area.

Owner:REPOWER SYST AG

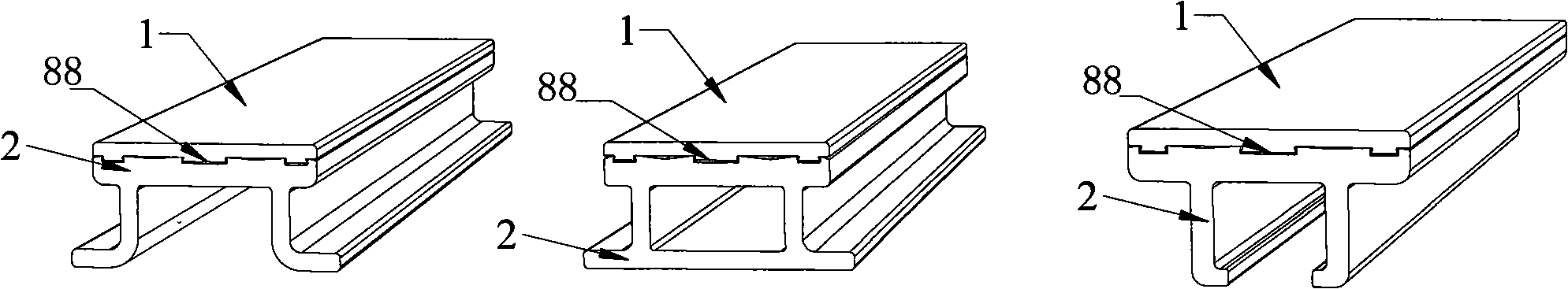

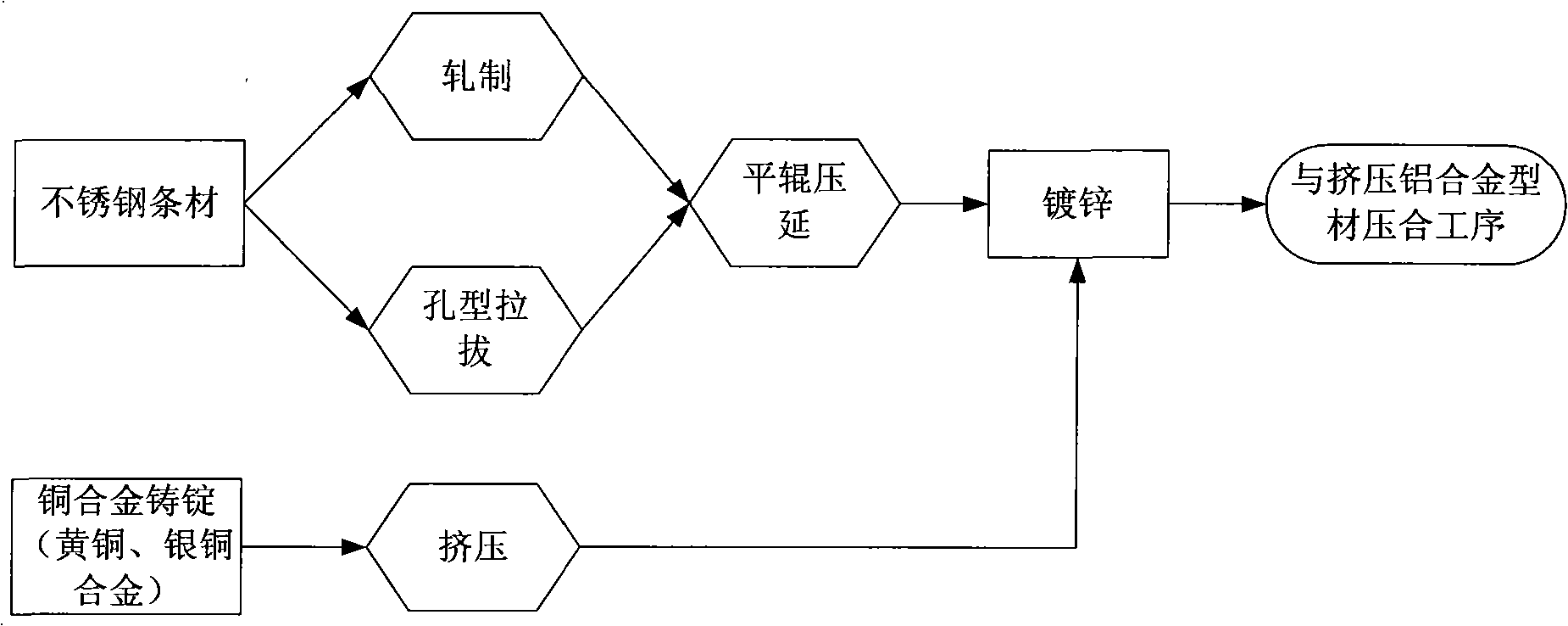

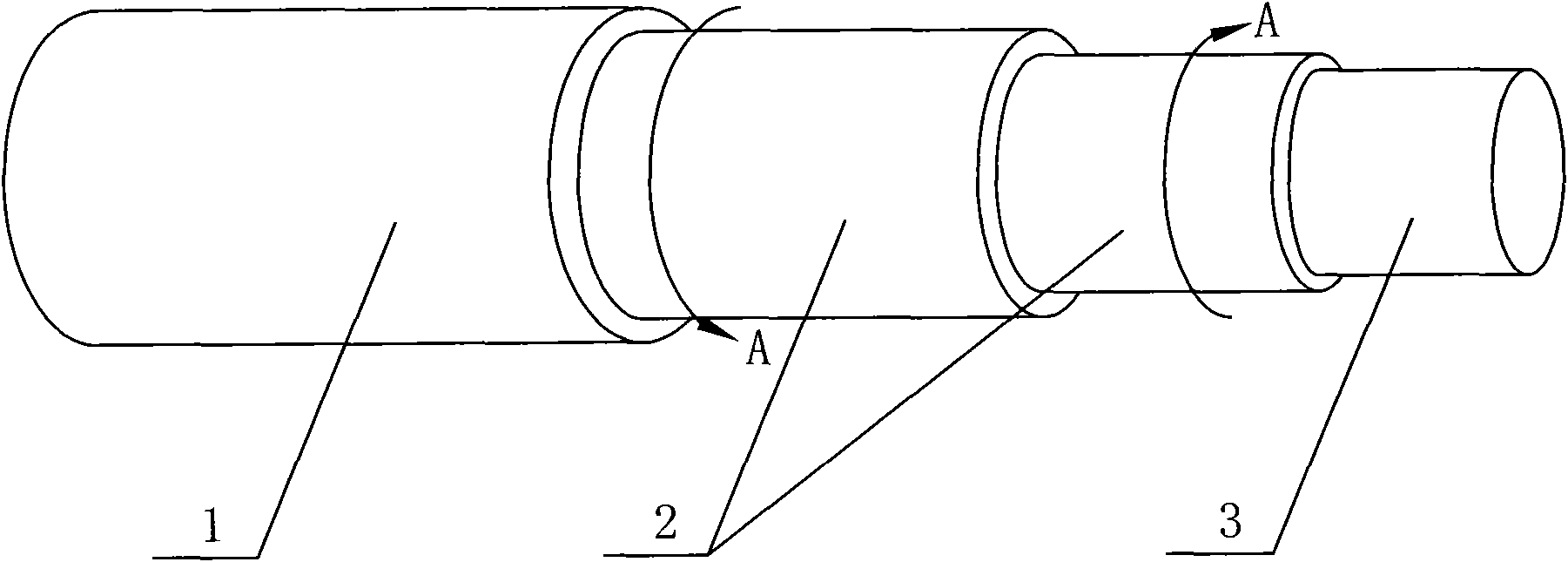

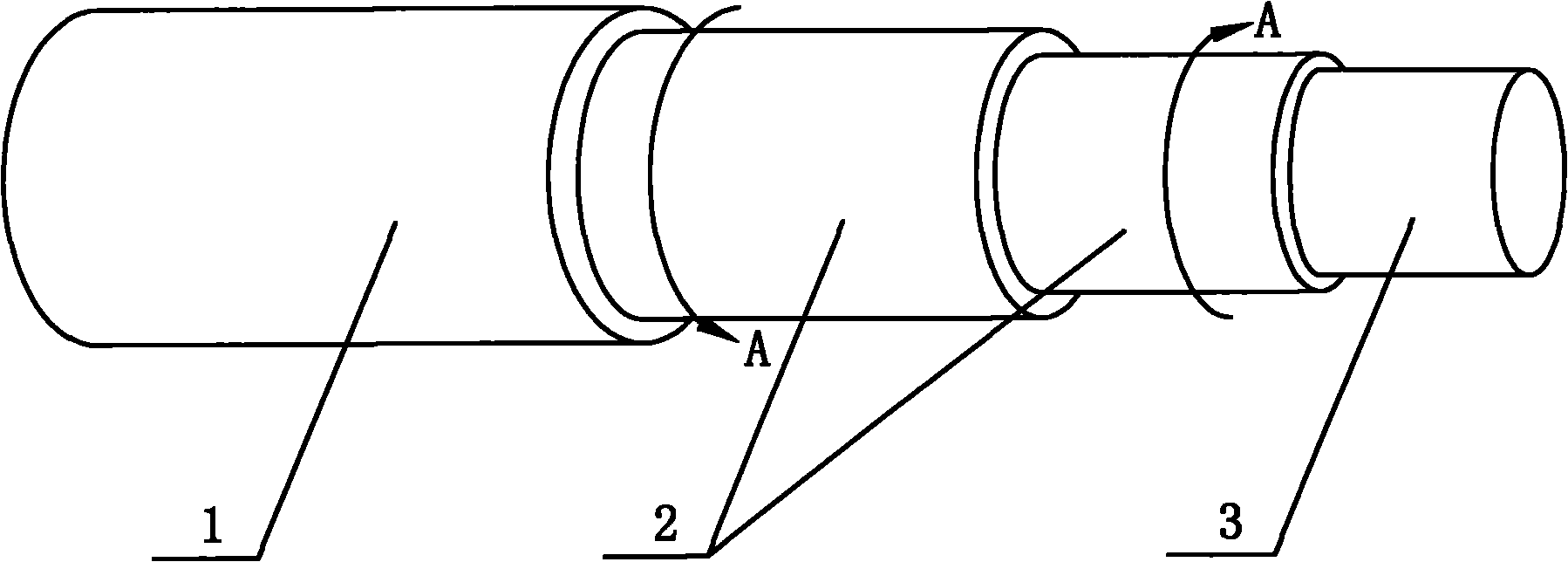

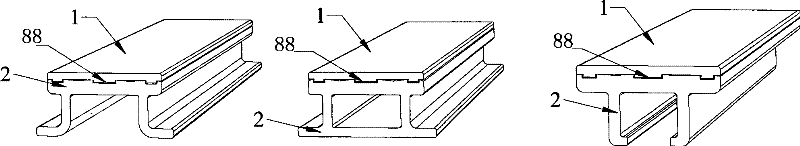

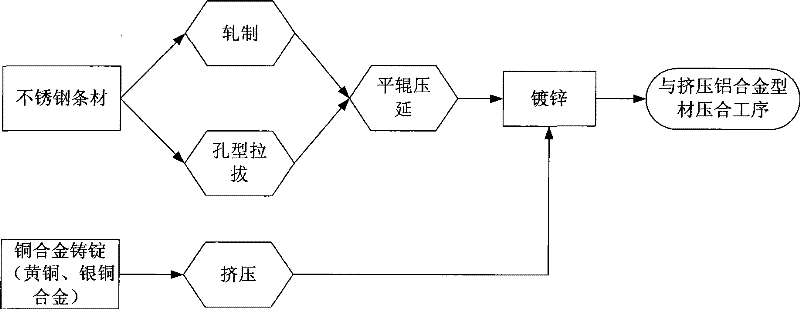

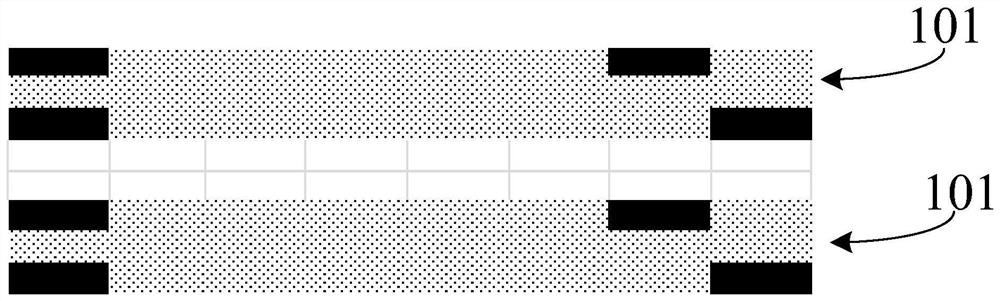

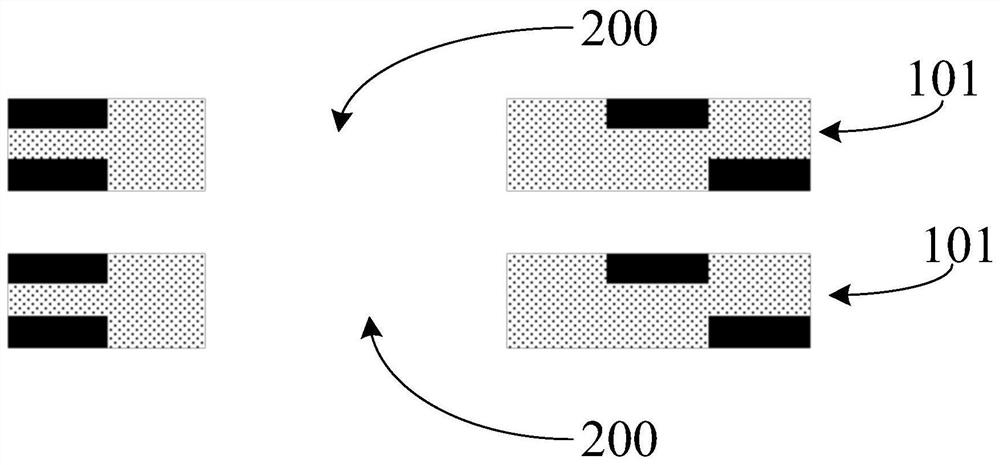

Composite power supply rail and method for producing the same

ActiveCN101327750ASimple designSimple production processLaminationLamination apparatusHard metalMetallic materials

The present invention discloses a complex conductor rail, and comprises a matrix and a contact body. The contact body is made of hard metal material with wear resistance and excellent conductivity; the matrix is made of metal material softer than the contact body; the rail also comprises a plating layer which is arranged between the matrix and the contact body; the plating layer is made of metal material which has excellent compatibility to the metal materials of the matrix and the contact body, and has excellent conductivity; the contact body is stitched to the matrix after being processed by the plating layer. The present invention also discloses a manufacturing method of the complex conductor rail, which comprises forming a blank of the contact body, and a blank of the matrix; one side of the blank of the contact body is a contact surface, and the other side is a compounding surface of the blank of the contact body; the compounding surface is processed by plating; one side of the blank of the matrix is the compounding surface of the matrix, which corresponds to the compounding surface of the blank of the contact body; the blank of the contact body and the blank of the matrix are stitched after being processed by plating. The metal contact surface of the complex conductor rail has the advantages of excellent conductivity, high bond strength, and simple structure. The manufacturing method has the advantages of simple technology and low costs.

Owner:TONGJI UNIV

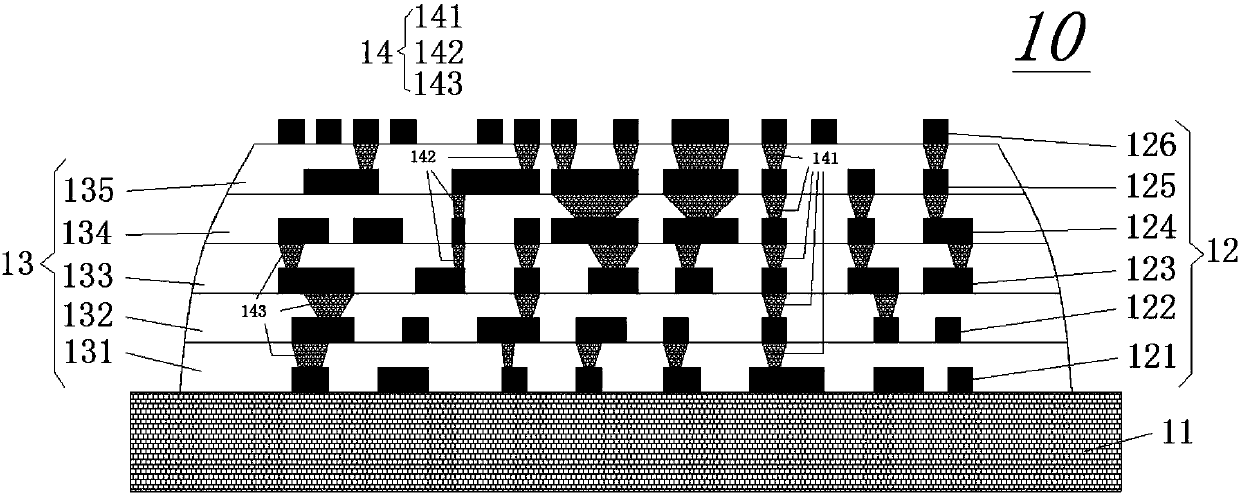

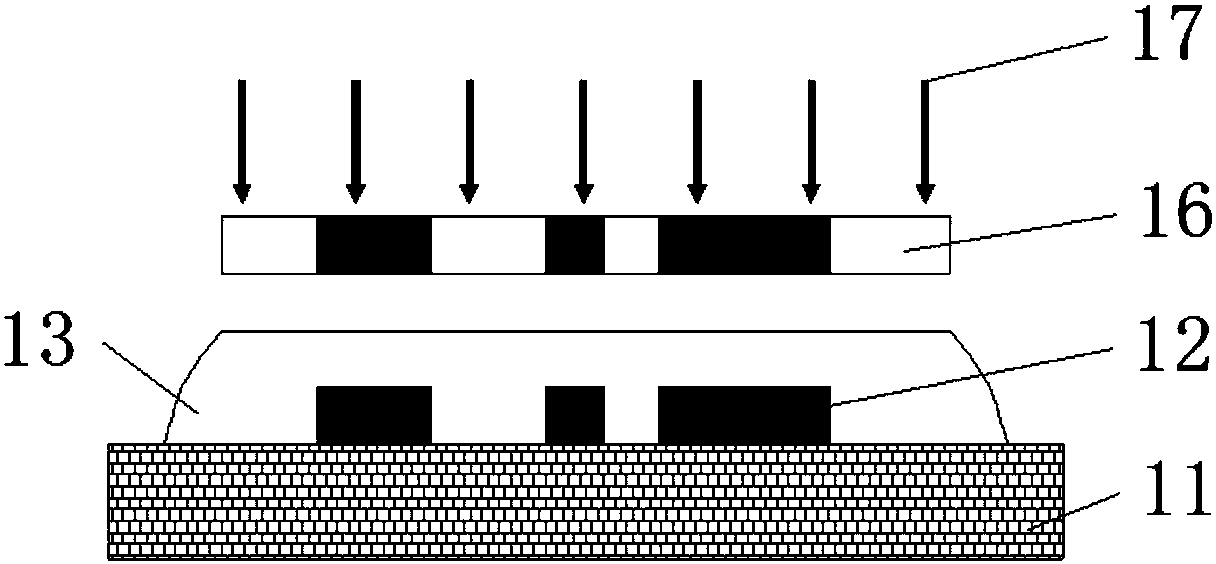

Preparation method of multi-layer flexible printed circuit

InactiveCN107846790ALow costEasy to operateFlexible printed circuitsElectrical connection printed elementsEngineeringSlurry

The invention discloses a preparation method of a multi-layer flexible printed circuit. The preparation method of the multi-layer flexible printed circuit comprises the following steps: providing flexible base materials of a first surface and a second surface which are arranged back to back; setting a first circuit layer on the first surface; setting a first insulating medium layer on the first circuit layer; processing and forming a number of through-holes on the first insulating medium layer; coating a conductive slurry or ink on the insulating medium layer, and making a part of the conductive slurry or ink flow into the through-holes and contact with the first circuit layer; then solidifying the conductive slurry or ink to form a second conductive layer on the insulating medium layer and form a conductive filler which can at least connect the first and second circuit layers electrically in the through-holes; and repeating the above operations until more than two insulating layers and more than three circuit layers are formed. The preparation method of the multi-layer flexible printed circuit is simple and easy to implement, has the advantages of good controllability, low cost and friendly environment, and benefits large-scale implementation; and the obtained printed circuit has super thin and soft characteristics.

Owner:SUZHOU NANOGRID TECH

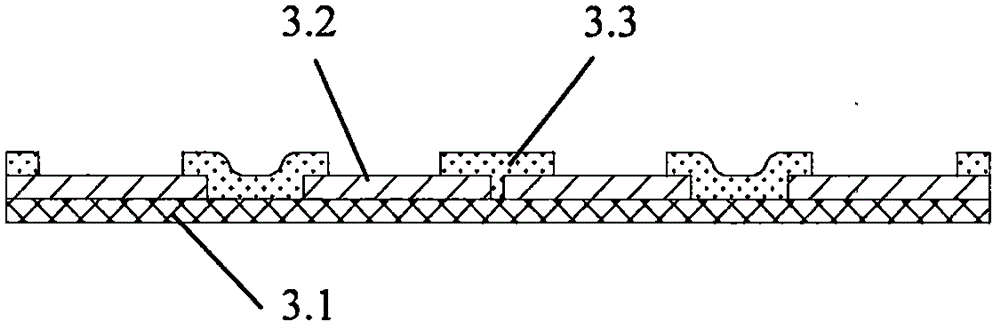

LED lamp band circuit board module containing multifunctional aluminum foil, and manufacturing method

InactiveCN106413249AIncreased current carrying capacityPlay a breakPrinted circuit aspectsMetallic pattern materialsMetal backedAluminium

The invention relates to an LED lamp band circuit board module containing a multifunctional aluminum foil, and a manufacturing method. Specifically, the back surface of a single-sided flexible circuit board is gelatinized; tin-conducting holes are punched by a die; then the positions, corresponding to the tin-conducting holes, of the back surface are covered with a metal back line, wherein an easily-tin-welded metal is at least on the surface of the metal back line; the metal back line is exposed out of the tin-conducting holes in the front surface of the single-sided flexible circuit board; the back line is covered with and packaged by multiple aluminum foil bands at certain spacings, wherein the width of the aluminum foil bands is greater than that of the back line; meanwhile, the aluminum foil bands are tightly glued by adhesive on the two sides of the back line for tightly clamping the back line in the middle to be contacted and conducted; element welding in an SMT patch manner is performed; the back line and a front surface circuit are welded together in the positions of the tin-conducting holes to enable the aluminum foil on the back surface, the metal back line, and the front surface circuit to be mutually conducted together to prepare the LED lamp band circuit board module containing the multifunctional aluminum foil. By virtue of the LED lamp band circuit board module and the manufacturing method, the problem that it is quite hard to realize connection and conduction between an aluminum circuit on the lamp band and a copper surface circuit is solved.

Owner:王定锋

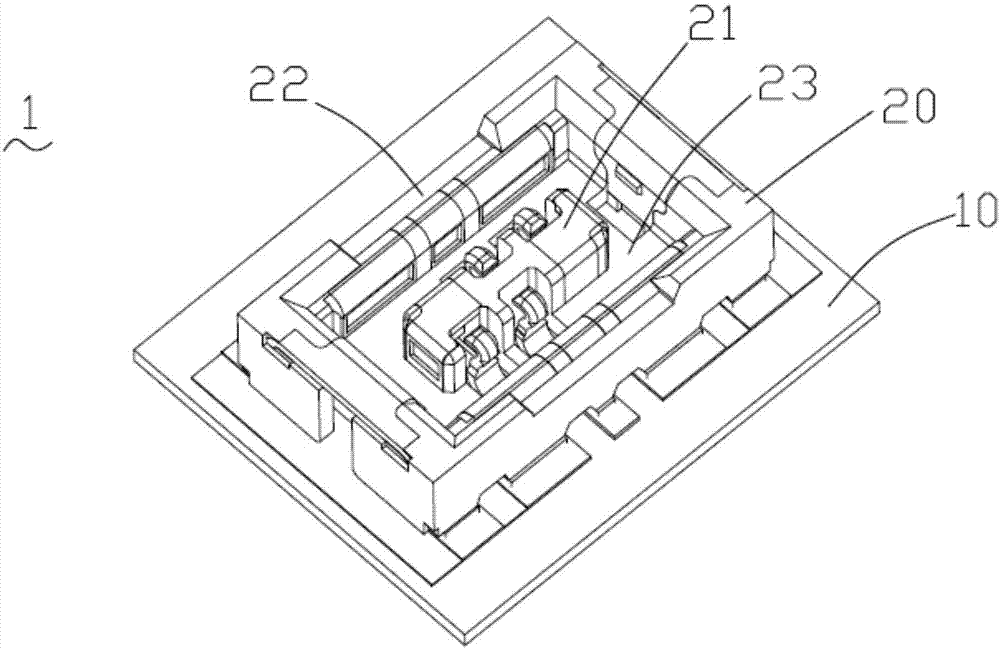

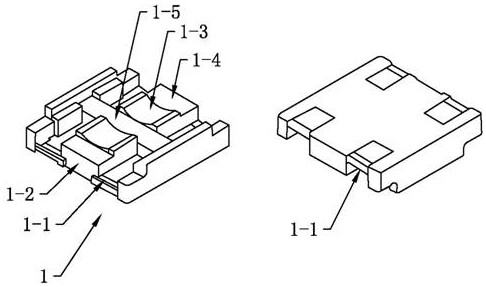

Large current board-to-board plug, socket and connector component

InactiveCN107394538AIncrease carrying currentIncreased current carrying capacityCoupling contact membersTwo-part coupling devicesElectrical and Electronics engineeringBoard-to-board connector

A high-current board-to-board plug includes a frame-shaped plug body, a plurality of plug signal terminals integrally formed in the plug body, and plug power terminals located laterally outside the plug signal terminals. The plug power terminals include The first contact portion located on the lateral outer wall of the plug body, and the second contact portion extending from the lateral inner wall of the plug body after being reversely bent from the upper end of the first contact portion, from the first The longitudinal ends of the contact portion are transversely bent and extend to the third contact portion on the longitudinal inner wall of the plug body, and the third contact portion is reversely bent from the top end of the third contact portion and then extends on the longitudinal outer wall of the plug body. The fourth contact part. The present application also includes a board-to-board socket and a board-to-board connector assembly.

Owner:SHENZHEN EVERWIN PRECISION TECH

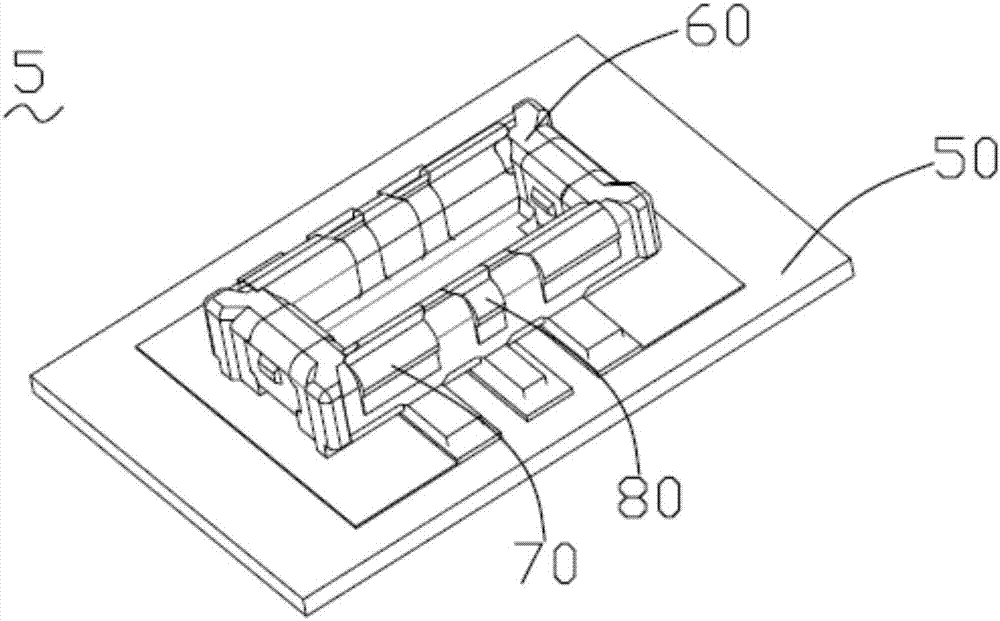

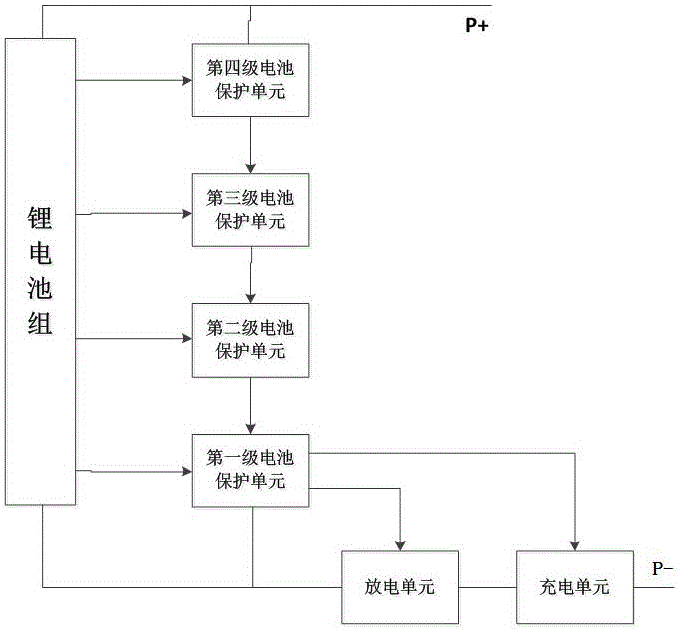

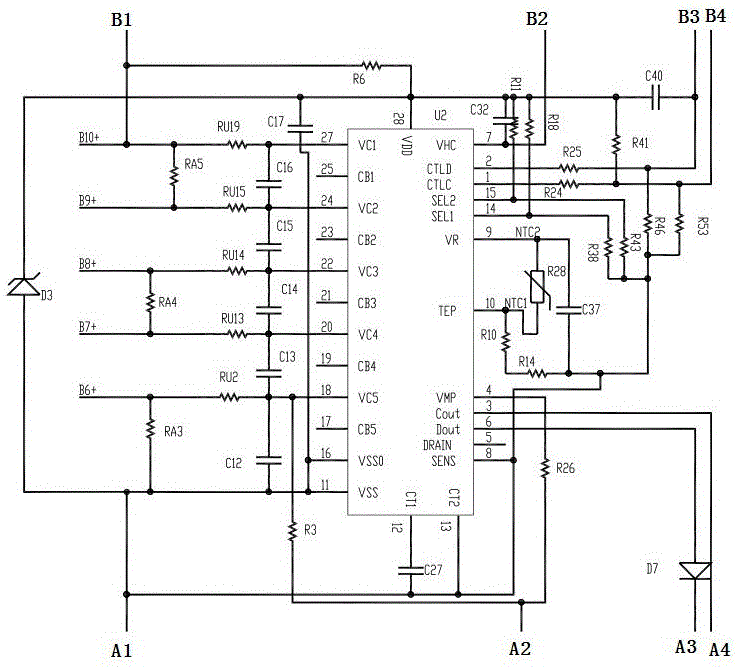

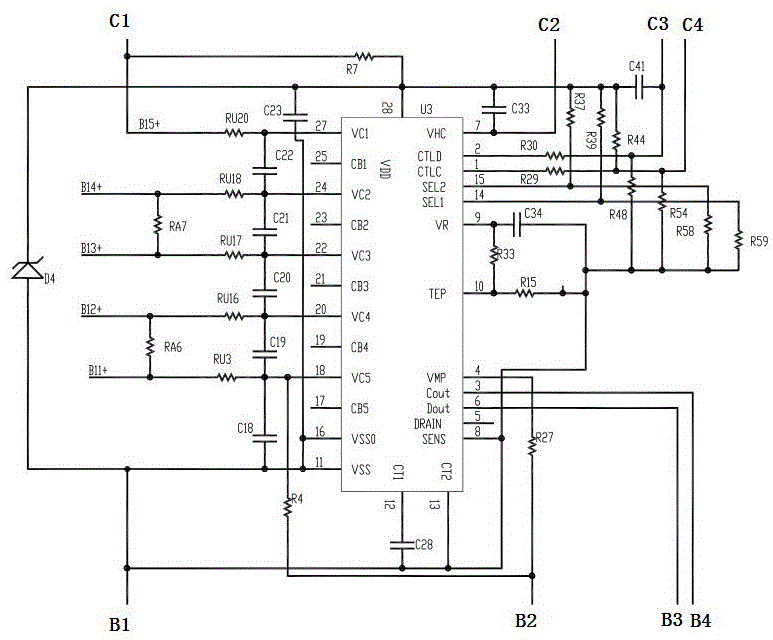

Lithium battery pack management system of smart balance car

InactiveCN106058955AReduce exceptionsExtended service lifeSafety/protection battery circuitsElectric powerEngineeringManagement system

The invention discloses a lithium battery pack management system of a smart balance car. The system includes a first stage battery protection unit, a second stage battery protection unit, a third stage battery protection unit, a fourth stage battery protection unit, a charging unit, and a discharging unit which are successively connected. A lithium battery pack includes 20 lithium batteries which are in successive series connection. The charging unit and the discharging unit are in series connection, and are connected to a circuit where the lithium battery pack is at. The system manages and protects the lithium battery pack of the smart balance car through a multi-stage battery protection unit, reduces the chances of unbalanced charging and discharging or occurrence of abnormities caused by too many single lithium batteries in a lithium battery pack, and increases service life of the lithium battery pack.

Owner:深圳天邦达科技有限公司

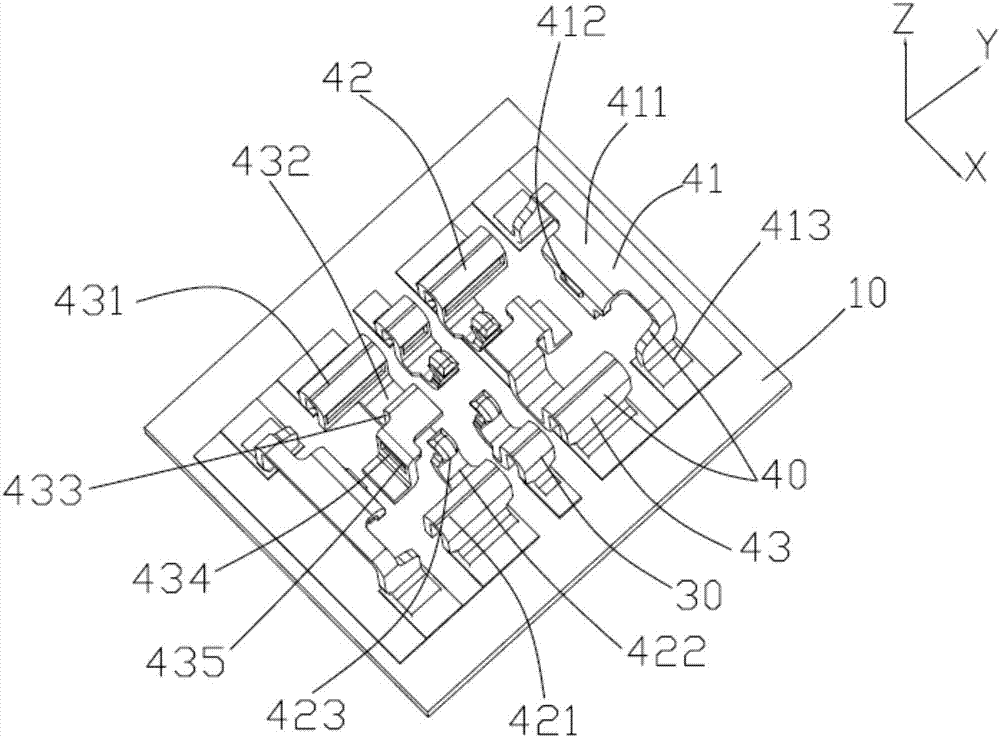

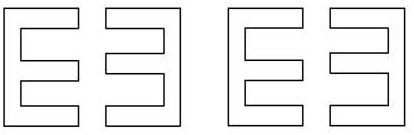

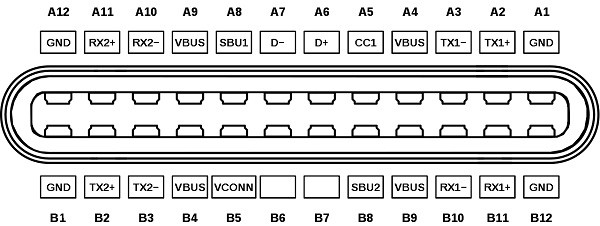

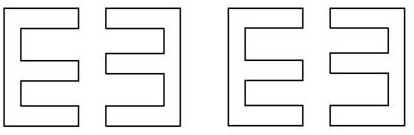

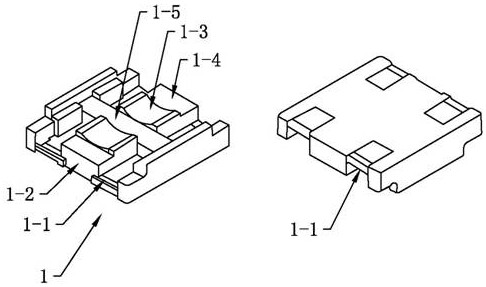

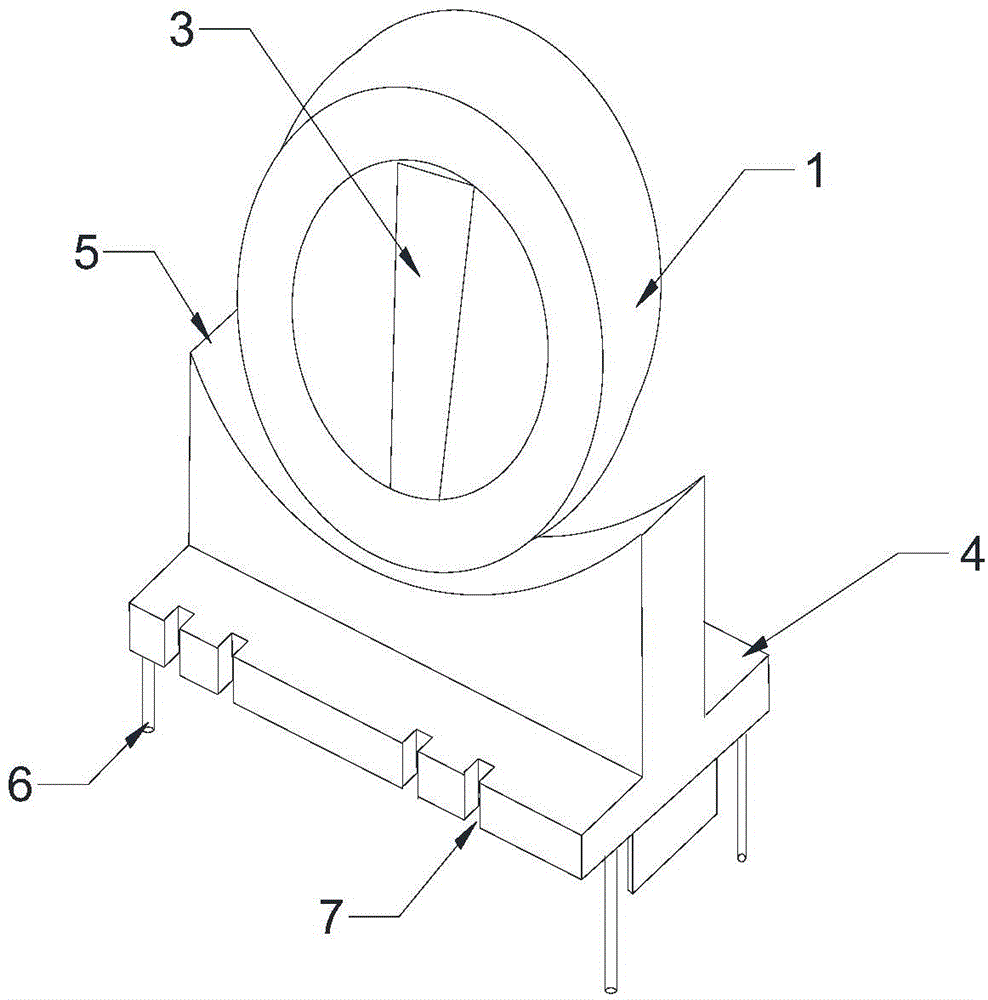

Manufacturing method of two-in-one structure inductor with air gap formed in side surface

ActiveCN111724980AEasy to installPlay efficientlyTransformers/inductances coolingTransformers/inductances coils/windings/connectionsStructural engineeringInductor

The invention discloses a manufacturing method of a two-in-one structure inductor with an air gap formed in the side surface. A base of the inductor is provided with four electrode grooves, so electrodes can be conveniently installed without using an additional positioning device for positioning. A tail end of the coil is close to a Z-shaped extension sheet of the electrode, so the extension sheetwraps the tail end of the coil and is pressed by a jig, the extension sheet of the electrode is Z-shaped, the extension sheet can just wrap the tail end of the coil, wrapping and welding of the extension sheet and the coil achieve a better conductive effect, and loss is effectively reduced. Compared with an inductor with an air gap formed in the front face, the inductor of the two-in-one structure with the air gap formed in the side surface and manufactured through the manufacturing method is compact in overall structure, small in size and good in performance. The preparation method disclosedby the invention is simple to operate and convenient to assemble, an air gap is formed in the formed independent complete side surface during production, and working efficiency is high.

Owner:GUANGZHOU DELOOP ELECTRONICS DEVICES

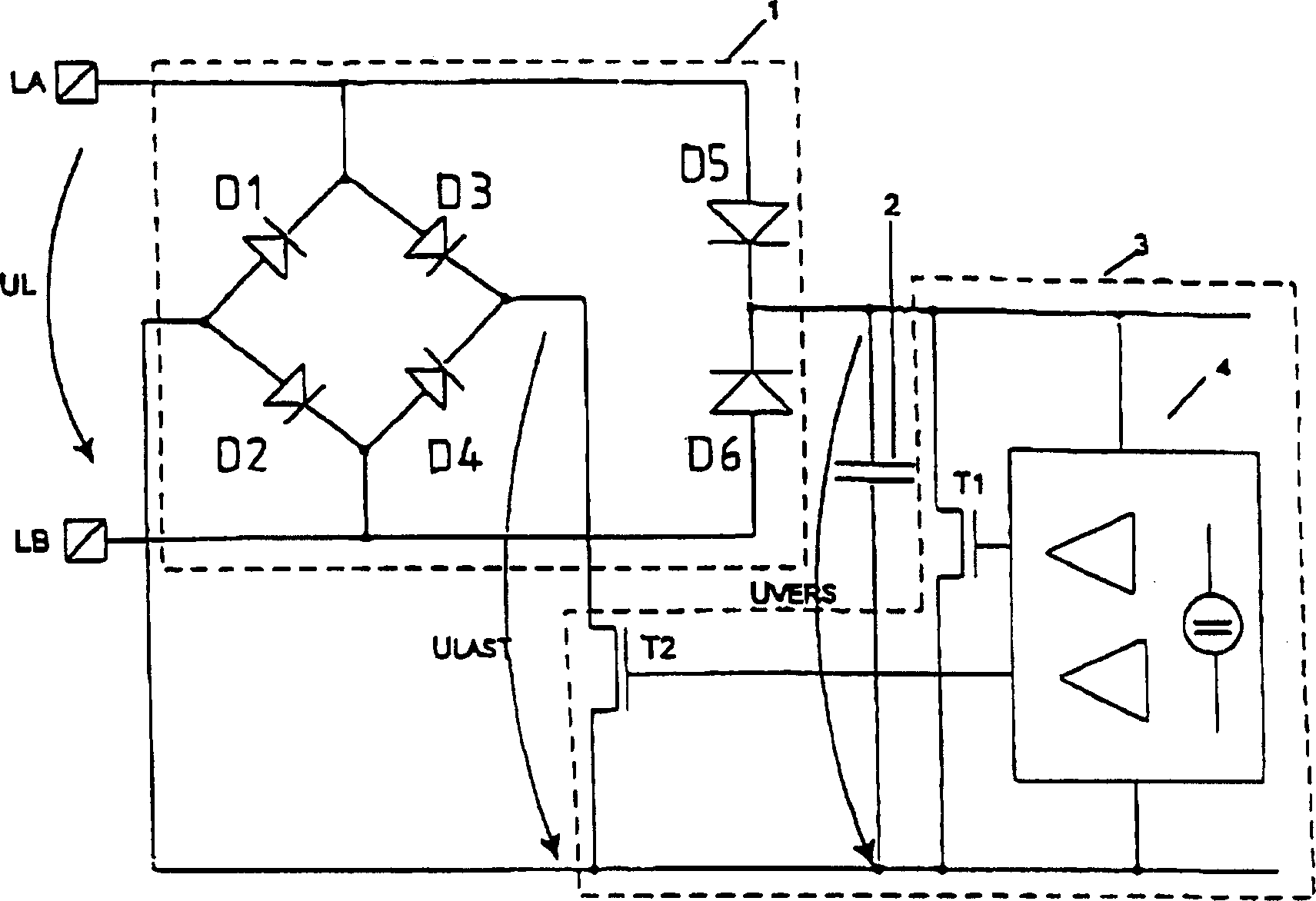

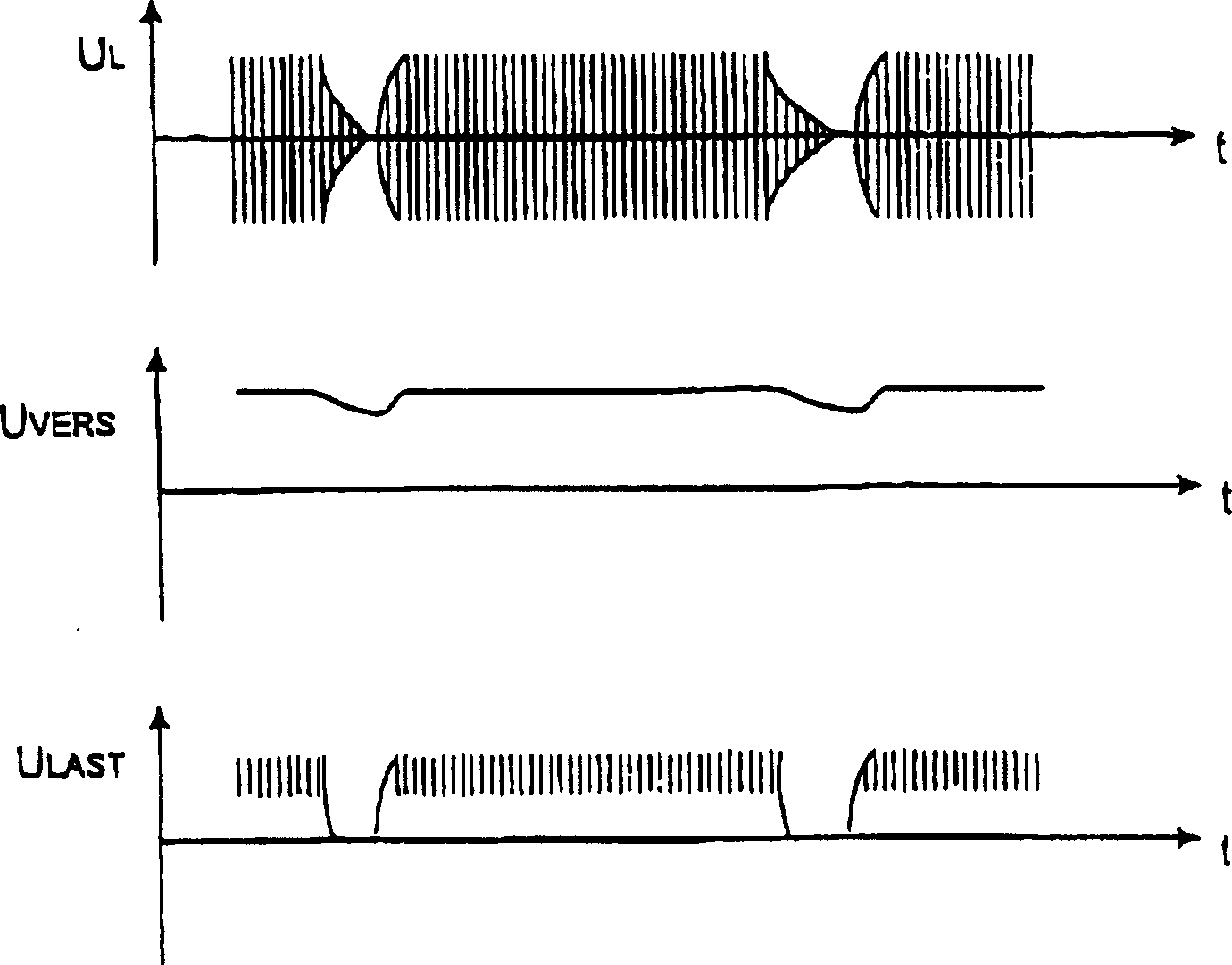

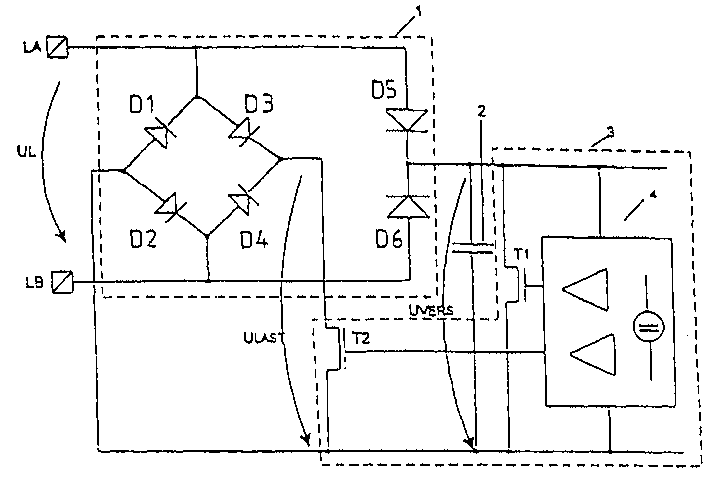

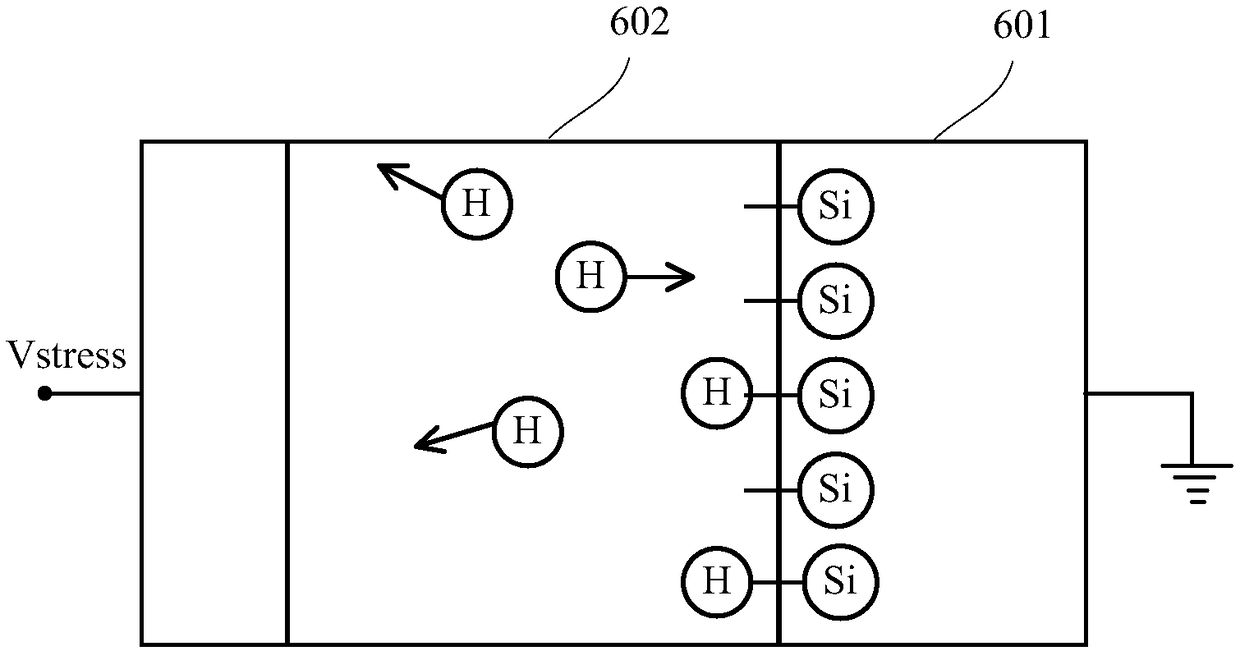

Supply voltage processing circuit and data carrier with supply voltage processing circuit

InactiveCN1133950CIncreased current carrying capacityAccelerated dissipationNear-field systems using receiversRecord carriers used with machinesEngineeringCapacitor

Proposed are two parallel control stages each with one transistor (T1, T2). The transistor (T2) forms part of the indirect parallel control stage and acts directly on the rectifier. It can take relatively high currents and is therefore relatively slow. The transistor (T1) forms part of the direct control stage and acts in parallel with the support capacitor. As a result of the coarse adjustment effected by transistor (T2), it is required to take only small currents and can therefore have very rapid control characteristics. Owing to the coarse adjustment effected by transistor (T2), the alternating voltage at the antenna connections (LA and LB) collapses rapidly if the HF signal is interrupted. This means that the transmission rate with pause interval modulation can be increased. Electrostatic chargings also derived from the transistor (T2), thus obviating the need for additional protective circuits.

Owner:NXP BV

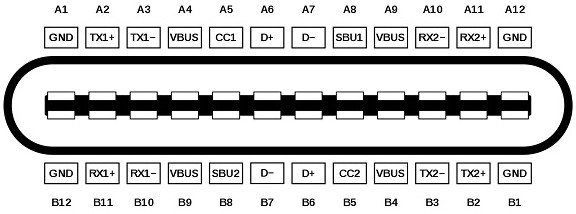

Type-C male end connector adopting non-porous PCB

PendingCN112421315AReduce manufacturing costImprove yield rateCoupling contact membersElectrical connection printed elementsElectrical connectionStructural engineering

A Type-C male end connector of a non-porous PCB is adopted, terminals used for achieving GND electrical connection of a power supply and VBUS electrical connection of the power supply are double-end double-pin PINs manufactured in a common mode, and the front ends of the double-end double-pin PINs are each provided with two fork-shaped terminals which are vertically arranged side by side to form afork shape. The rear ends of the double-end double-pin PINs are each provided with two fork-shaped weld legs which respectively correspond to the fork-shaped terminals and are vertically arranged side by side to form a fork shape, and are also each provided with a connecting part which is integrally formed between the fork-shaped terminals and the fork-shaped weld legs. In the double-end double-pin PIN, the two fork-shaped terminals are respectively embedded in the top wall and the bottom wall of a plugging port, and the two fork-shaped weld legs are respectively welded on the front surface and the back surface of the PCB so as to correspondingly construct power supply GND electrical connection or power supply VBUS electrical connection. GND bonding pads and VBUS bonding pads corresponding to the GND electrical connection of the power supply and the VBUS electrical connection of the power supply are arranged on the front surface and the back surface of the PCB. GND connecting wires and VBUS connecting wires are arranged on the front face and the back face of the PCB respectively, the GND connecting wires enable the GND bonding pads located on the same face to be connected, and theVBUS connecting wires enable the VBUS bonding pads located on the same face to be connected.

Owner:李庐山

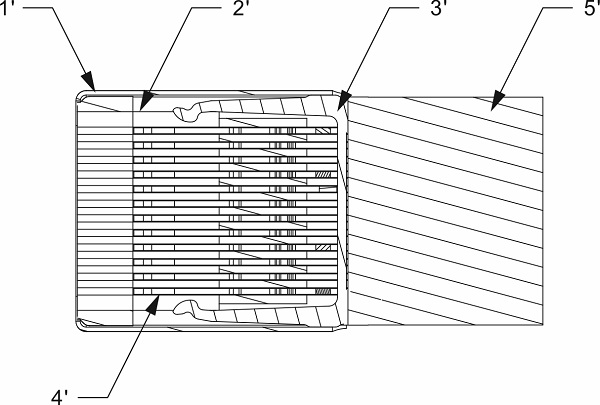

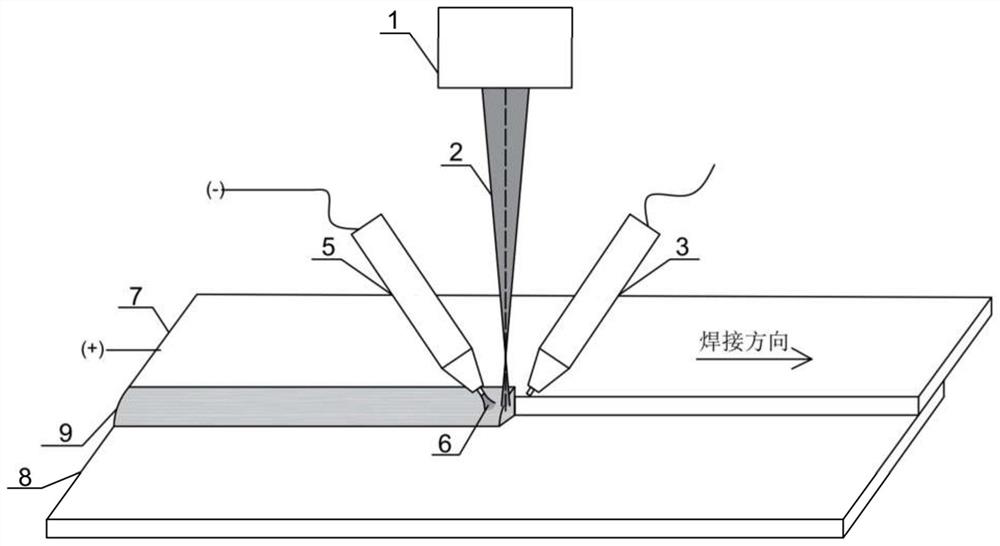

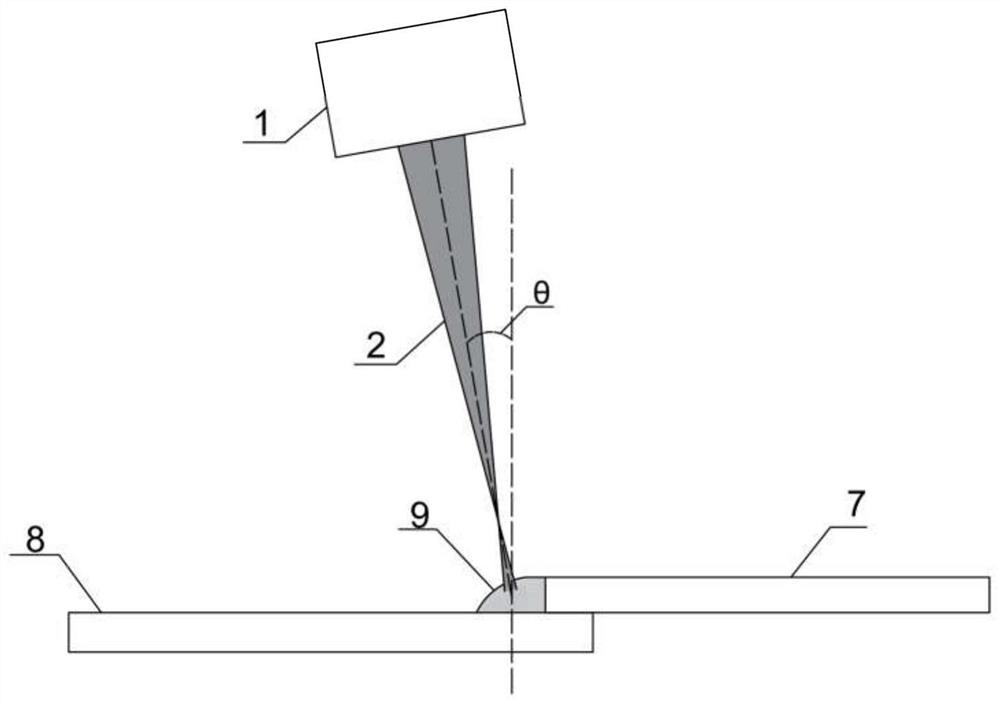

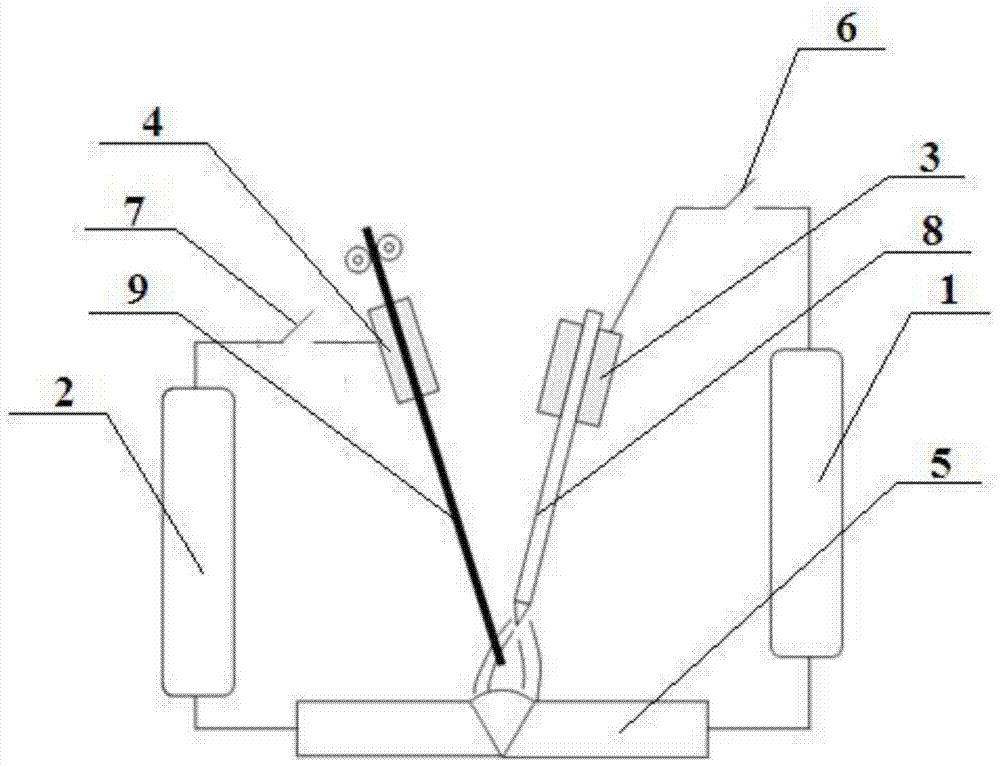

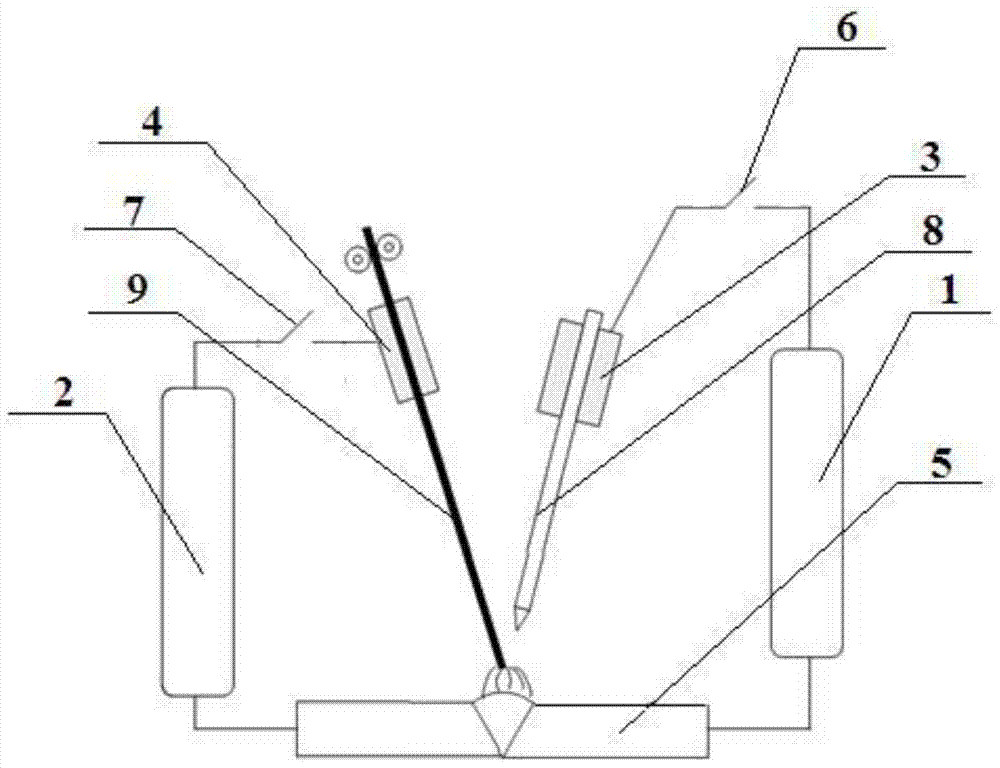

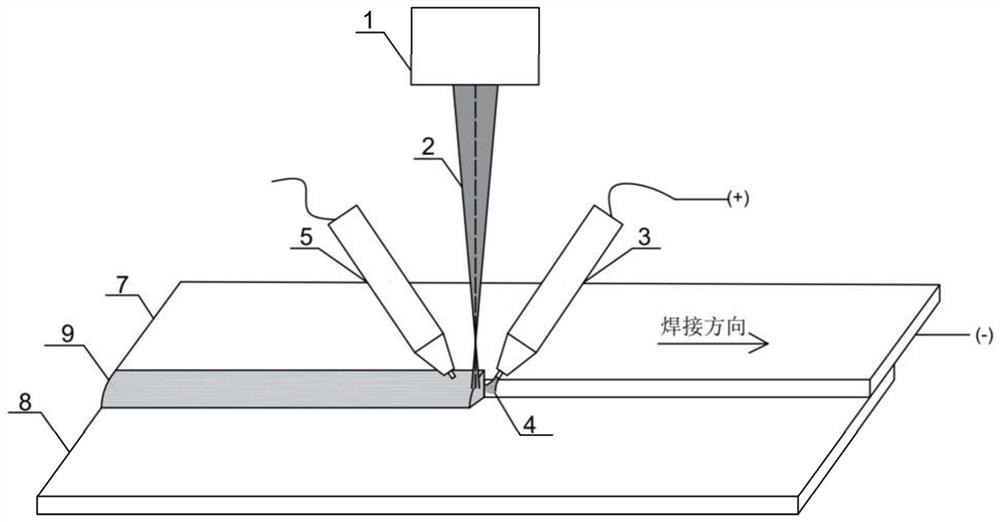

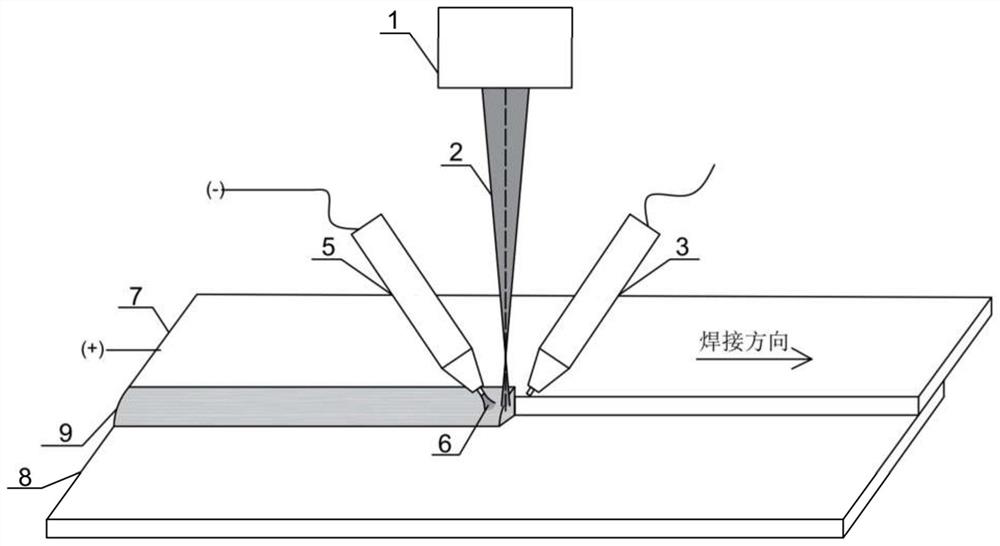

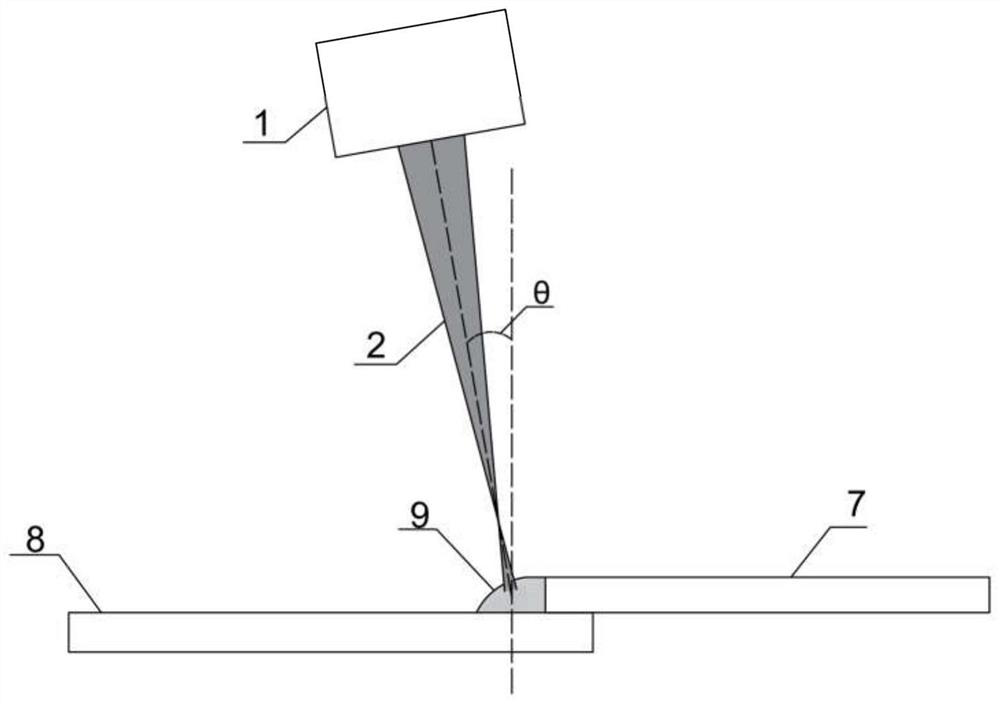

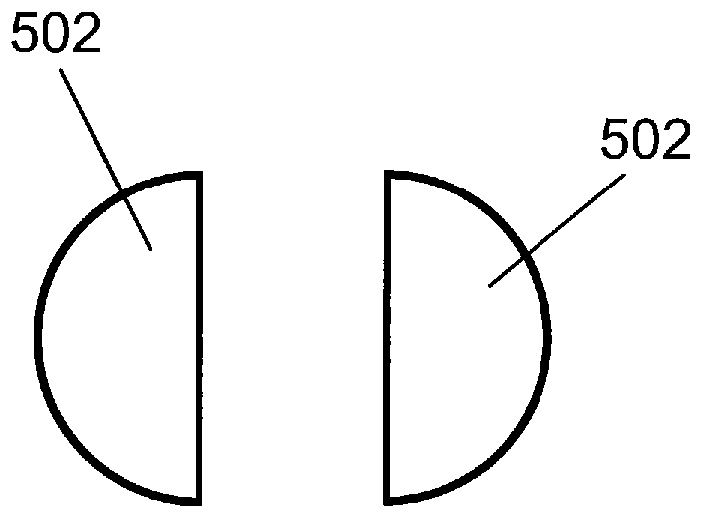

Laser-double TIG electric arc composite self-fluxing brazing method for aluminum alloy and stainless steel

ActiveCN113427132AAvoid disadvantagesImprove energy utilizationLaser beam welding apparatusLap jointLaser beams

The invention discloses a laser-double TIG electric arc composite self-fluxing brazing method for aluminum alloy and stainless steel. The laser-double TIG electric arc composite self-fluxing brazing method comprises the steps that a laser beam-double TIG electric arc composite heat source is adopted for welding a lap joint of an aluminum alloy plate on the upper portion and stainless steel on the lower portion, the aluminum alloy is melted through the composite heat source, the stainless steel is heated, and a brazing interface is formed. A laser beam is a variable power pulse scanning laser beam; the double TIG electric arc comprises a positive polarity TIG electric arc and a reverse polarity TIG electric arc; the direct-current reverse connection TIG welding gun and the direct-current forward connection TIG welding gun are located on the front side and the rear side of the laser beam in the welding direction correspondingly. In the welding process, the laser beam scans the surface of a workpiece to be welded, it is guaranteed that 2 / 3-3 / 4 laser heat is on the aluminum alloy plate, 1 / 3-1 / 4 laser heat is on a stainless steel plate, the direct-current reverse connection TIG welding gun and the direct-current forward connection TIG welding gun conduct arc starting alternately, reverse polarity TIG electric arcs and high-power laser pulses form the composite heat source, and positive polarity TIG electric arcs and low-power laser pulses form the composite heat source. According to the welding method, a self-fluxing brazing welding joint with excellent mechanical properties can be obtained.

Owner:GUANGDONG CSR RAIL TRAFFIC VEHICLE CO LTD

Small-diameter and high-power flexible heating cable and preparation method thereof

InactiveCN102164429AImprove machinabilityImprove work efficiencyHeating element shapesHeating element materialsMetallurgy

The invention discloses a small-diameter and high-power flexible heating cable, and a preparation method thereof. The small-diameter and high-power flexible heating cable is provided with a heating alloy wire core line in an innermost layer; the external part of the heating alloy wire core line is lapped with an insulating fiber layer; and the outer surface of the insulating fiber layer is coated with a high temperature resistance splicing and sealing coating layer. The preparation method comprises the following steps: a) electrothermal alloy is subjected to fine wire drawing processing and is machined into the heating alloy wire core line with the diameter of 0.4-0.7 mm, and the heating alloy wire core line is subjected to high temperature annealing and softening in the hydrogen protective atmosphere; b) the heating alloy wire core line is lapped with the multi-layer insulating layer, and is made into a small high-power special heating cable with the diameter smaller than Phi 1.0 mm; c) the high temperature resistance splicing and sealing coating is sprayed onto the surface of the insulating fiber layer of the heating cable; and d) the heating cable is aired at the room temperature and is placed in an oven, and after 1-hour heat preservation at 200 DEG C and solidification process, the small-diameter and high-power flexible heating cable can be obtained. In the invention, the small high-power special heating cable with the diameter smaller than Phi 1.0 mm can be manufactured; and the design requirement of generating high power instantly in a narrow space can be met, and the ice removal and prevention efficiencies and effects of relative components can be improved.

Owner:CHONGQING MATERIALS RES INST

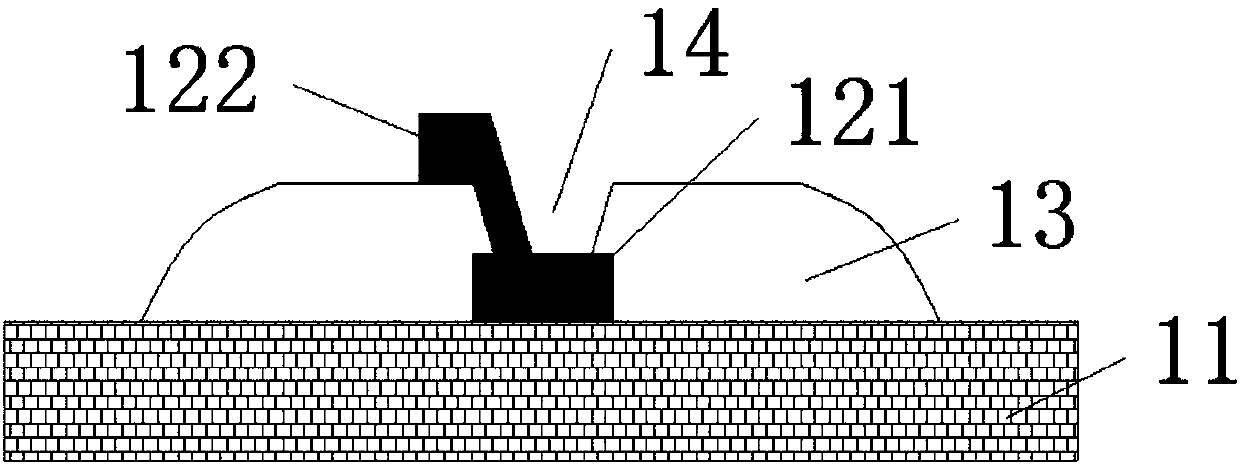

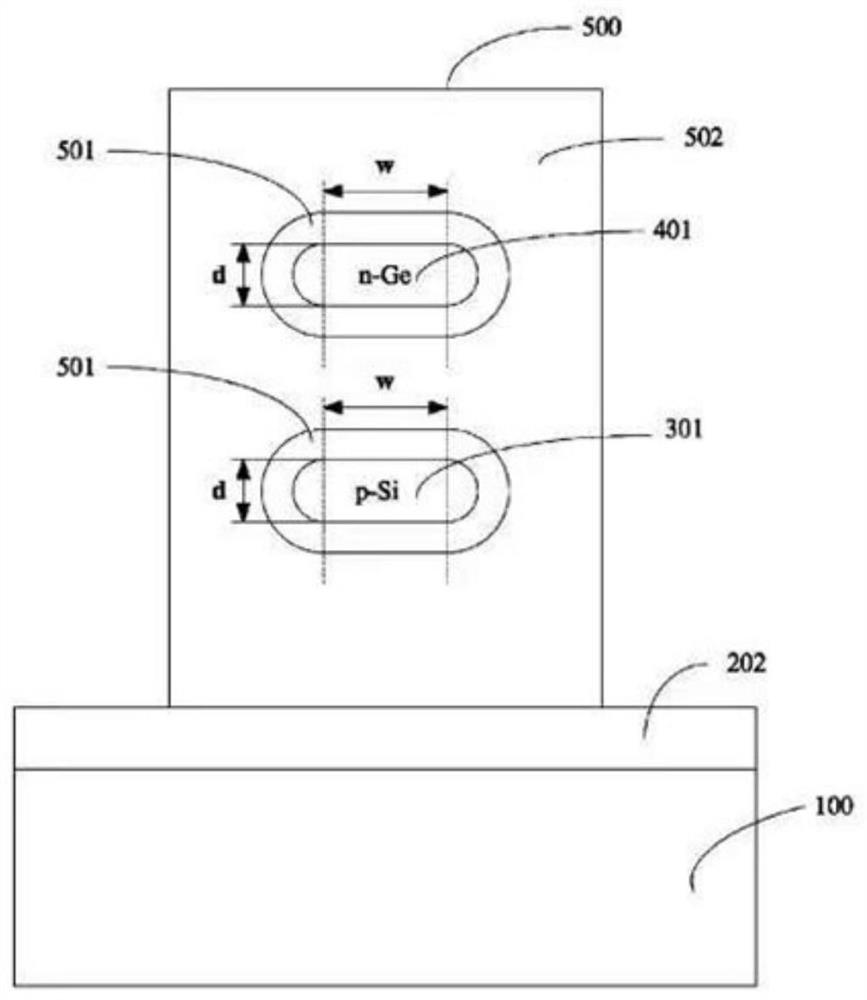

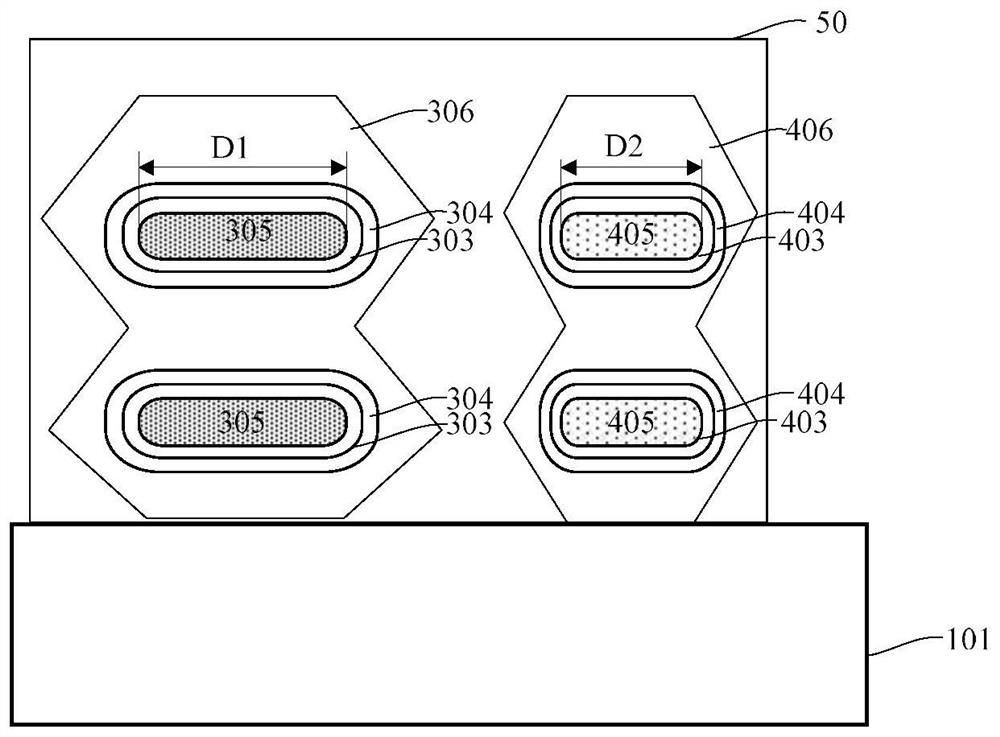

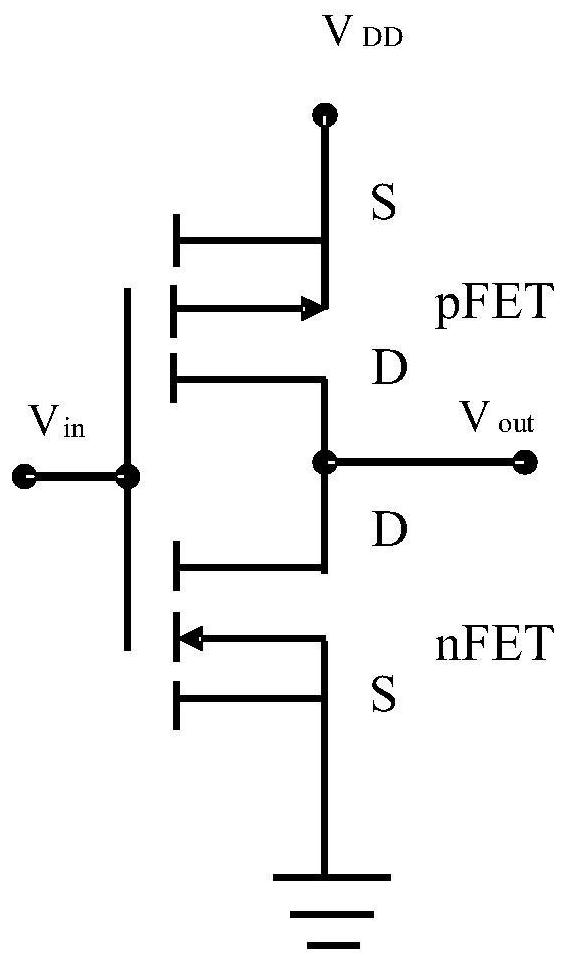

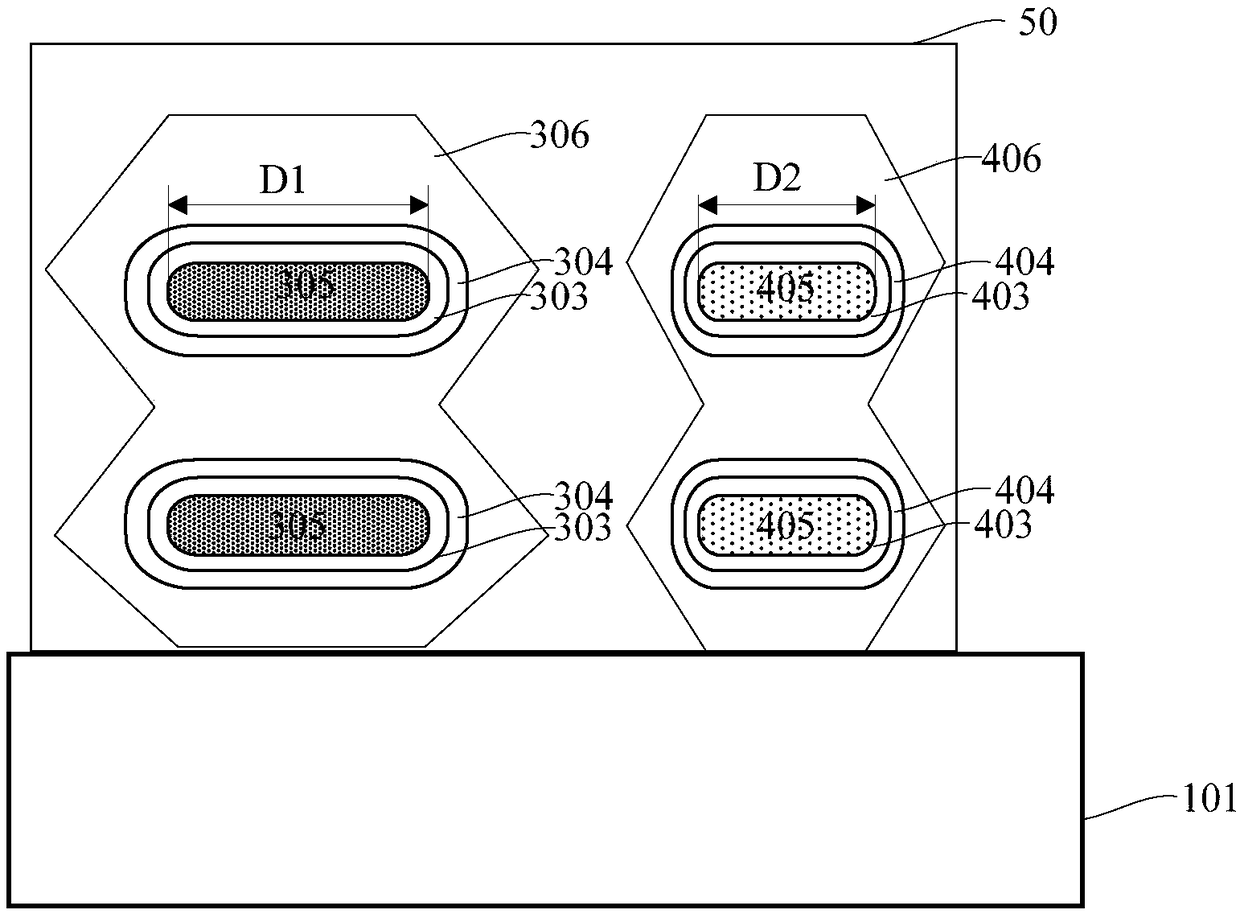

Semiconductor device structure and fabrication method thereof

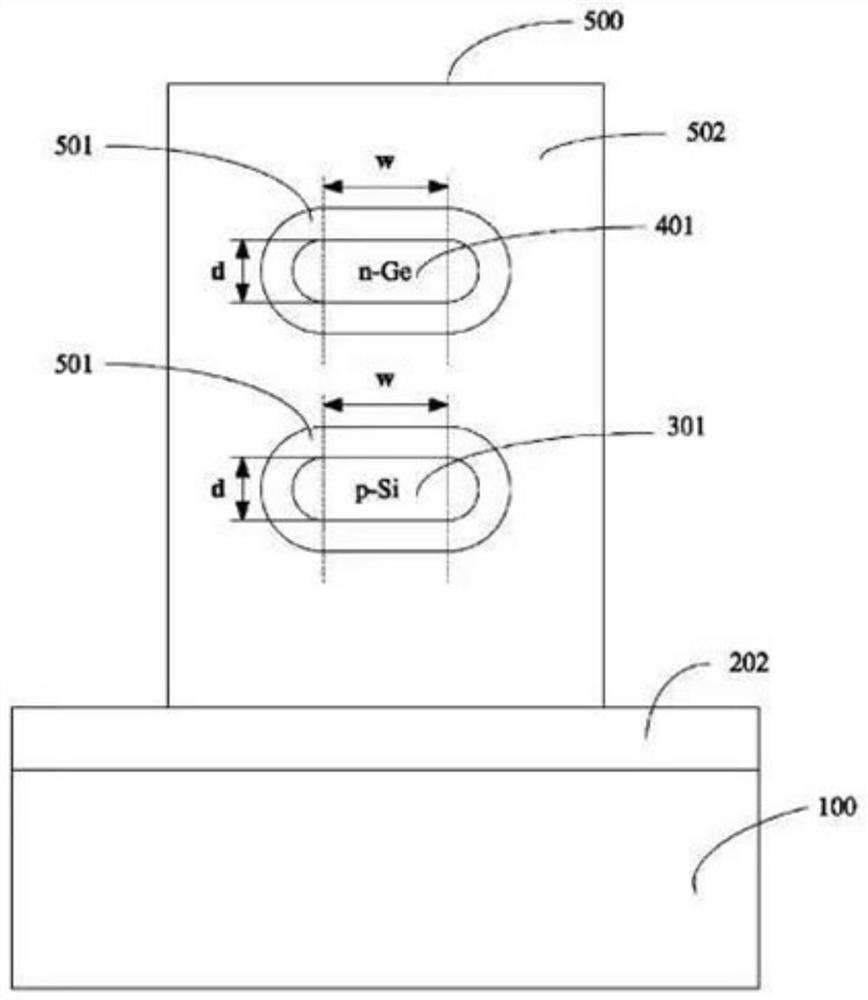

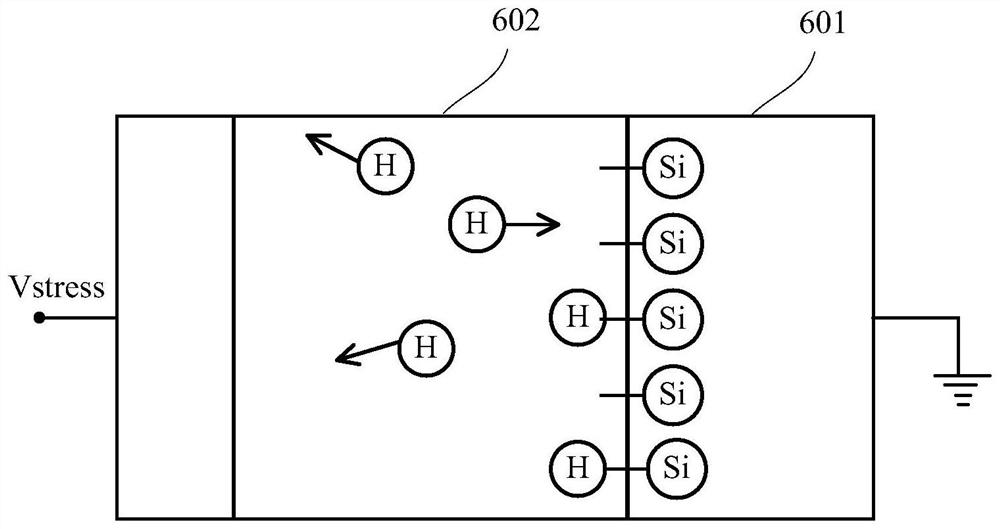

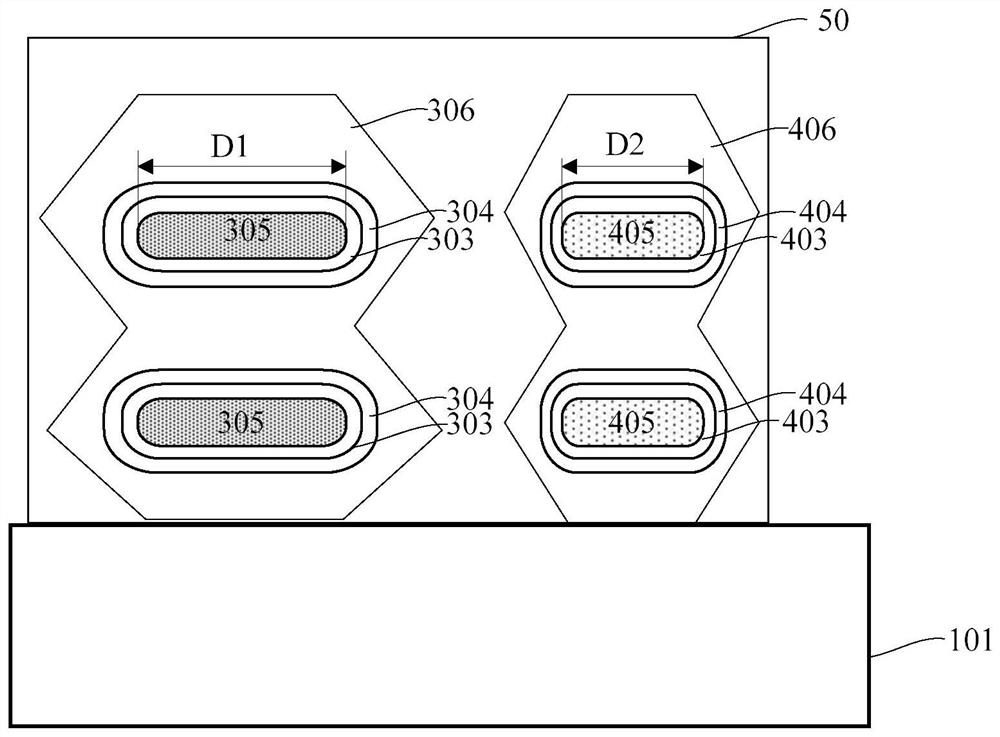

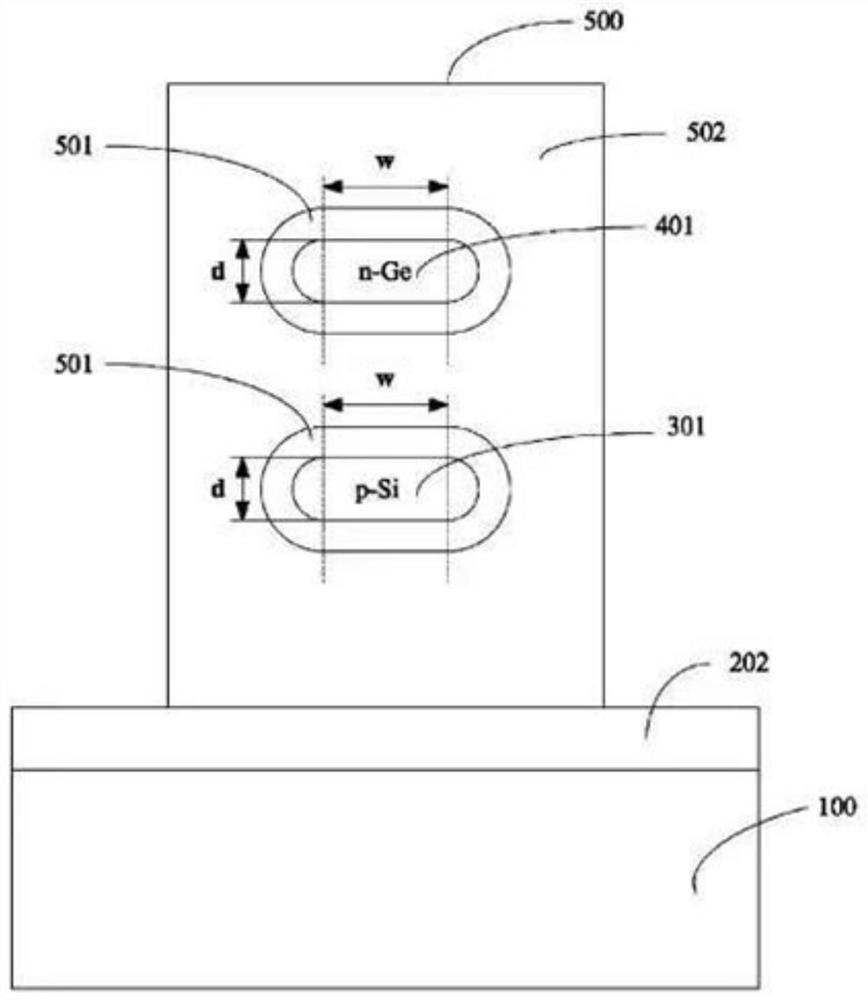

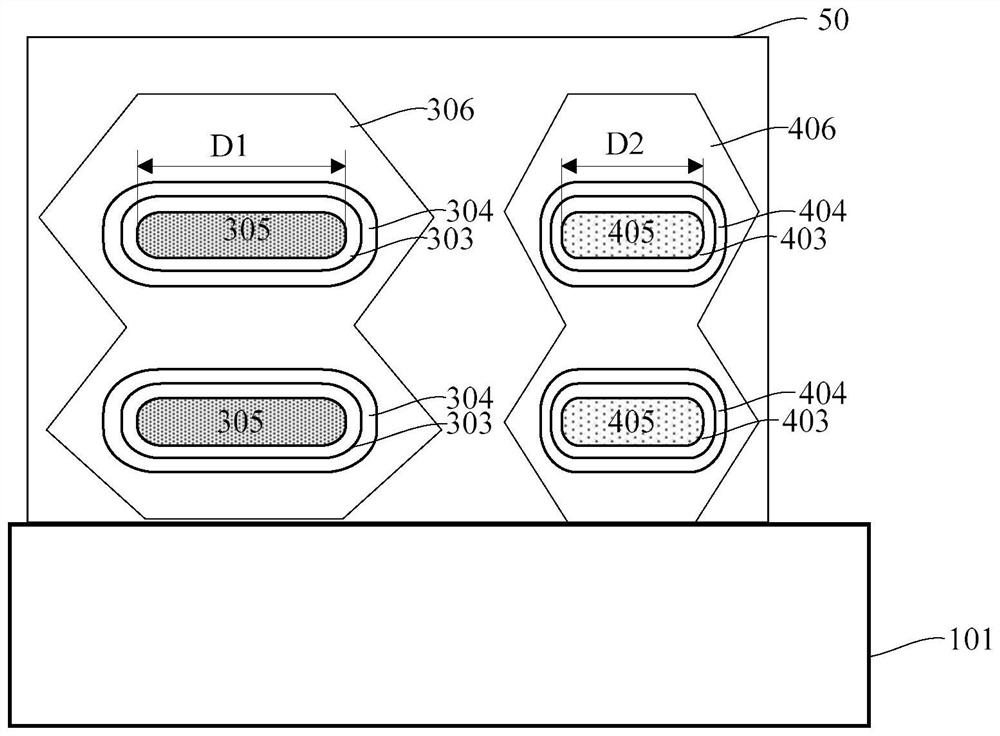

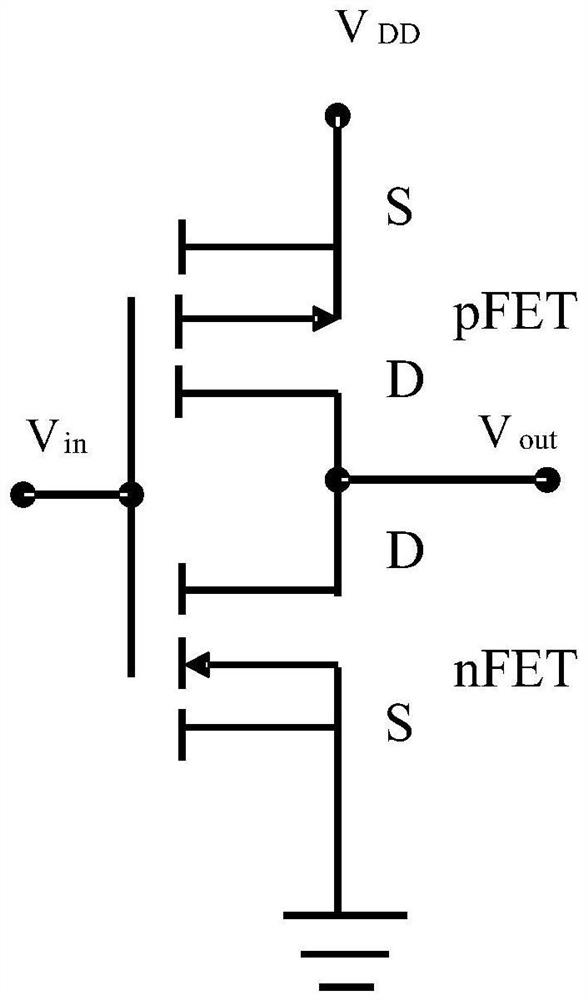

ActiveCN109300896BReduce channel lengthHighly integratedTransistorNanoinformaticsGate dielectricDevice material

This invention provides a semiconductor device and a manufacturing method thereof. The semiconductor device comprises a subtract; a P-type semiconductor channel suspended on the subtract, a silicon-deuterium passivation layer on the P-type semiconductor channel; an N-type semiconductor channel suspended on the subtract, a silicon-deuterium passivation layer on the N-type semiconductor channel; a gate dielectric layer, wrapped around the P-type semiconductor channel and the N-type semiconductor channel; a gate electrode layer, wrapped around the gate dielectric layer; a P-type source region and a P-type drain region, connected to two ends of the P-type semiconductor channel respectively; an N-type source region and an N-type drain region, connected to two ends of the N-type semiconductor channel respectively; wherein a cross-sectional width of the P-type semiconductor channel is greater than that of the N-type semiconductor channel. The present invention has ability to realize multi-layer staking under unit area, and reducing the length of the channel effectively so as to reduce channel effect and improve carrying capacity and the reliability of the device.

Owner:SIEN QINGDAO INTEGRATED CIRCUITS CO LTD

Alternative composite welding method of aluminum alloy tig and mig

InactiveCN105215516BFast meltingHigh speedArc welding apparatusWelding/soldering/cutting articlesAlloy compositeWeld seam

The invention relates to a method for compositely welding an aluminum alloy in a TIG welding manner and a MIG welding manner alternately. The method disclosed by the invention aims to solve the problems that a conventional aluminum alloy welding method is low in welding efficiency, poor in weld-seam formation, complicated in welding equipment, unstable in process, poor in flexibility, and high in cost. The method comprises the following steps: the output end of the positive pole of a constant-current TIG welding power source is connected with a workpiece to be welded; the negative pole of the constant-current TIG welding power source is connected with a tungsten electrode clamp; a TIG welding gun is clamped on the tungsten electrode clamp; a melting-electrode welding wire is arranged in a gas protection sleeve on the side wall of the TIG welding gun; the positive pole of a constant-voltage MIG welding power source is connected with a melting-electrode clamp; a MIG welding gun is clamped on the melting-electrode clamp; the negative pole of the constant-voltage MIG welding power source is connected with the workpiece to be welded; through an IGBT switch, the constant-current TIG welding power source and the constant-voltage MIG welding power source are controlled to be alternately switched on and off, so that welding is realized. The method disclosed by the invention is used for welding the aluminum alloy.

Owner:HARBIN INST OF TECH

Manufacturing method of two-in-one structure inductor with air gap on side surface

ActiveCN111724980BEasy to installPlay efficientlyTransformers/inductances coolingTransformers/inductances coils/windings/connectionsInductorMechanical engineering

Owner:GUANGZHOU DELOOP ELECTRONICS DEVICES

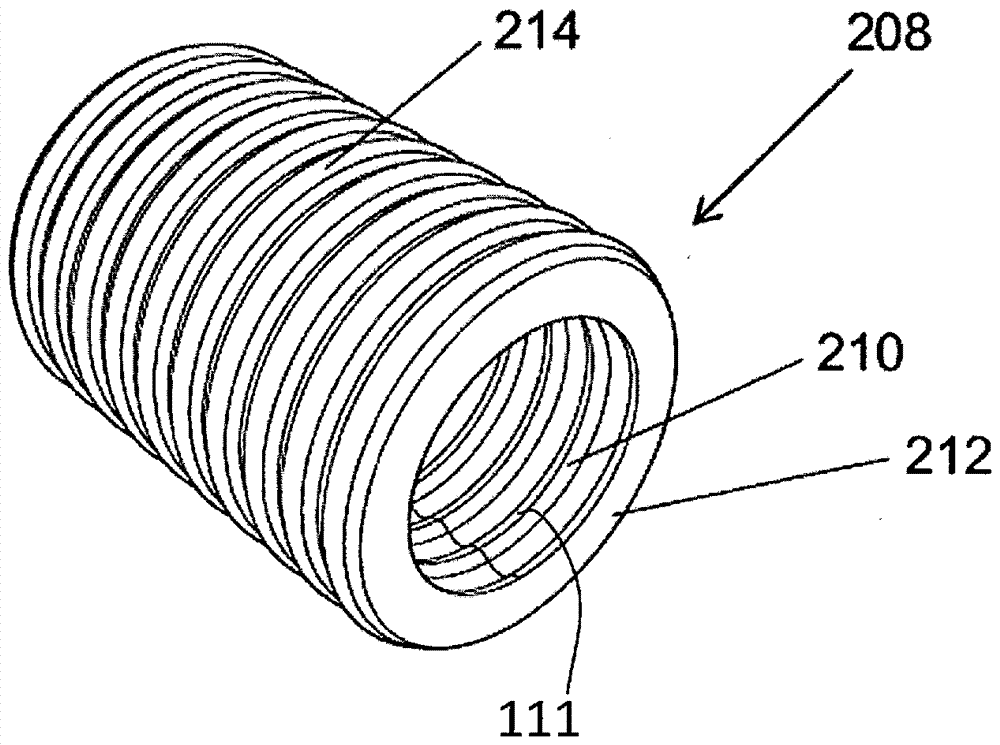

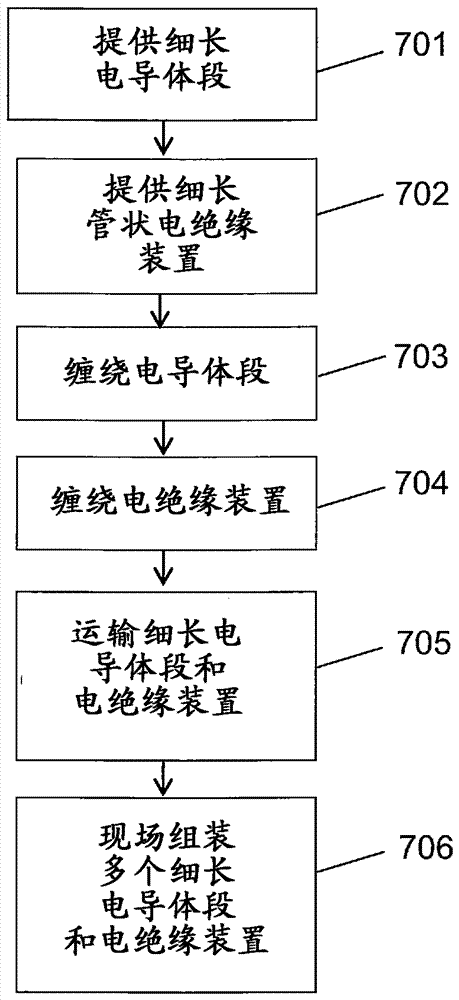

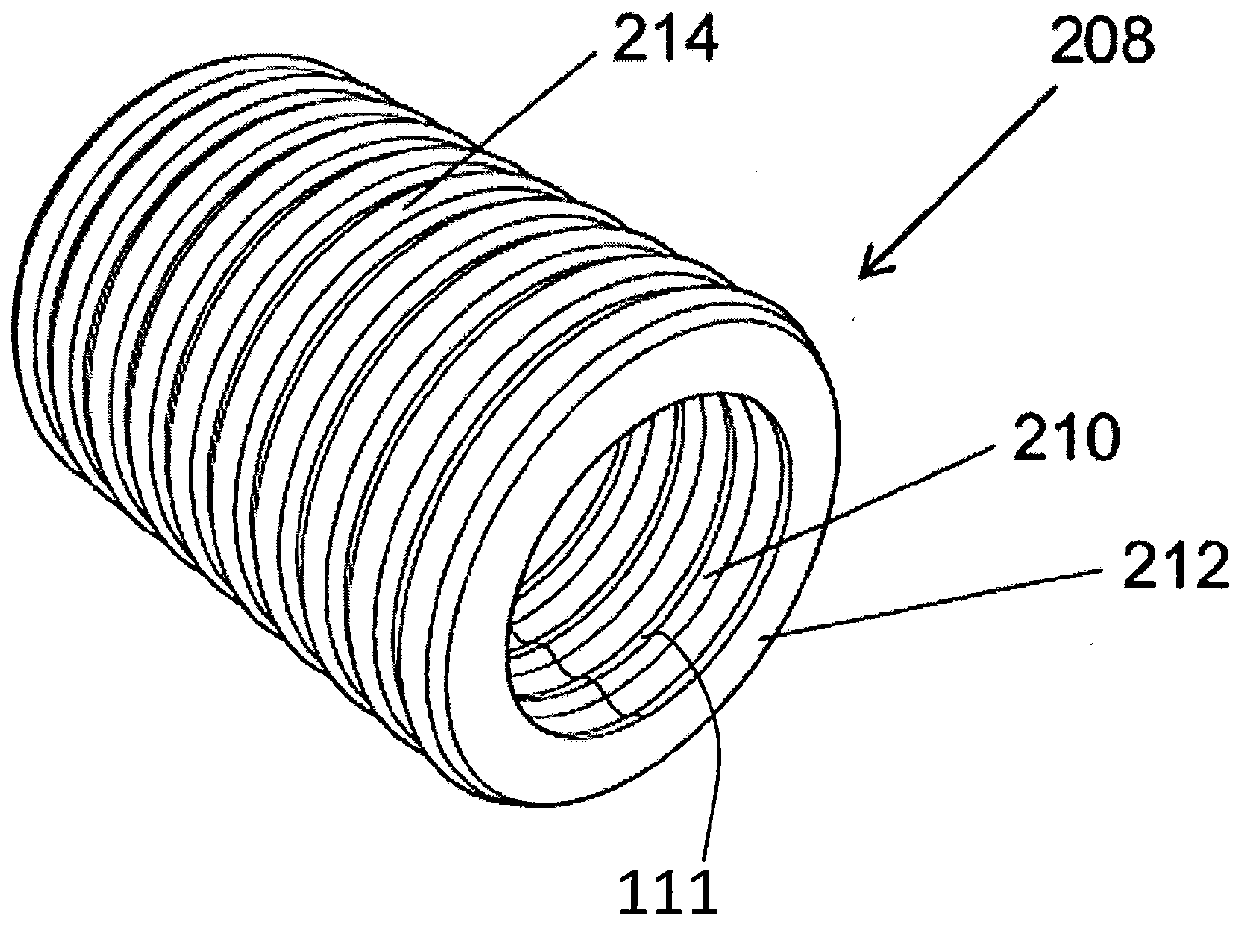

High voltage power transmission line

InactiveCN106856666AIncrease the cross-sectional areaShorten the lengthCable installations on groundCable installations in underground tubesElectrical conductorMechanical engineering

A HV power transmission line (106) with at least two tubular electrical insulation devices (108), at least one electrically uninsulated nominal conductor segment (102) and a joint (1 17) for jointing the ends of the insulation devices plus at least one power termination (109) for connecting the transmission line. The insulation device (108) is flexible, has an inner electrically conductive layer (1 10) at its inner wall surface, and is of such insulation quality that it can electrically insulate the conductor segment (102) from the exterior of the insulation device once inserted into the tubular insulation device. Once inserted the uninsulated conductor segment touches the inner electrically conductive layer (1 10) at an inner wall surface of the tubular electrical insulation device such that the inner electrically conductive layer (1 10) is on the same electric potential as the conductor segment in an operating state of the HV power transmission line each.

Owner:ABB (SCHWEIZ) AG

Composite power supply rail used by vehicle-ground power system in track transportation system and method for producing the same

ActiveCN101327750BIncreased current carrying capacityImprove adhesion strengthLaminationLamination apparatusHard metalMetallic materials

The present invention discloses a complex conductor rail used for vehicle to ground power supply system in rail transit system, and comprises a matrix and a contact body. The contact body is made of hard metal material with wear resistance and excellent conductivity; the matrix is made of metal material softer than the contact body; the rail also comprises a plating layer which is arranged between the matrix and the contact body; the plating layer is made of metal material which has excellent compatibility to the metal materials of the matrix and the contact body, and has excellent conductivity; the contact body is stitched to the matrix after being processed by the plating layer. The present invention also discloses a manufacturing method of the complex conductor rail, which comprises forming a blank of the contact body, and a blank of the matrix; the compounding surface is processed by plating; the compounding surface of the matrix corresponds to the compounding surface of the blank of the contact body; the blank of the contact body and the blank of the matrix are stitched after being processed by plating. The metal contact surface of the complex conductor rail has the advantages of excellent conductivity, high bond strength, and simple structure. The manufacturing method has the advantages of simple technology and low costs.

Owner:TONGJI UNIV

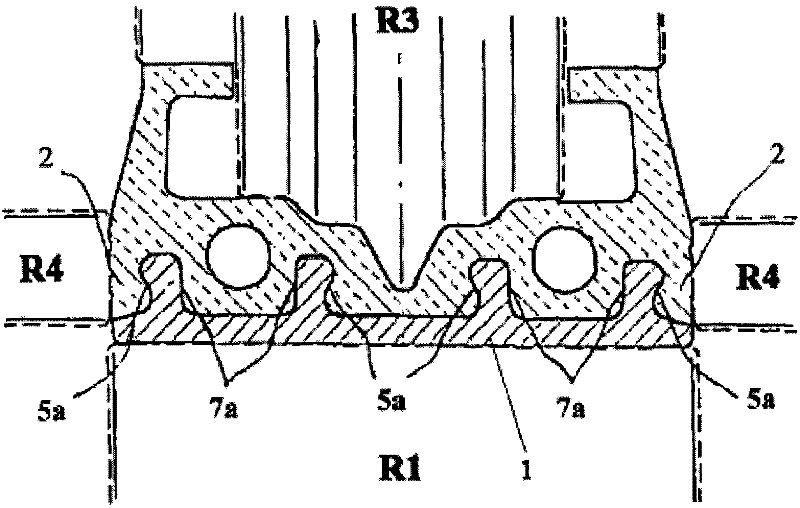

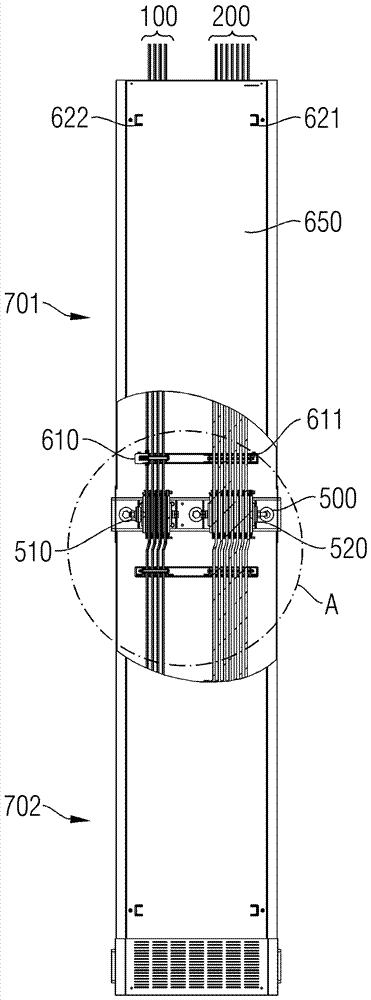

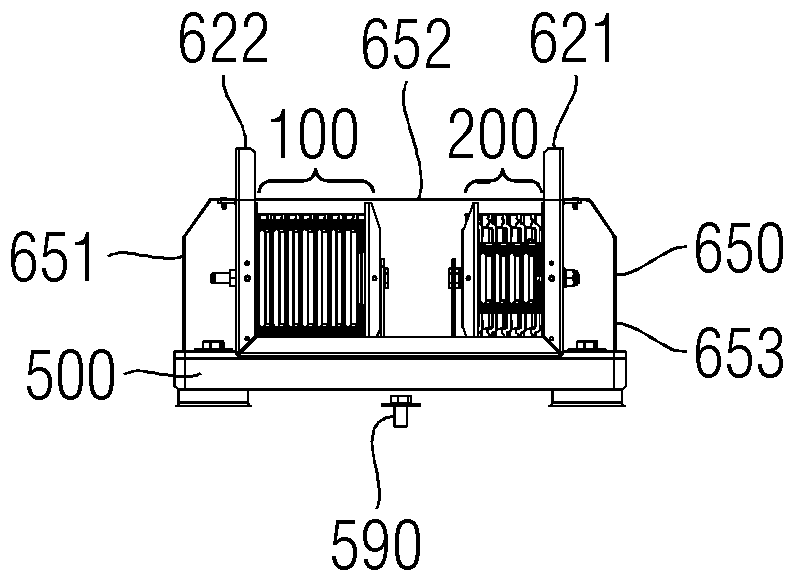

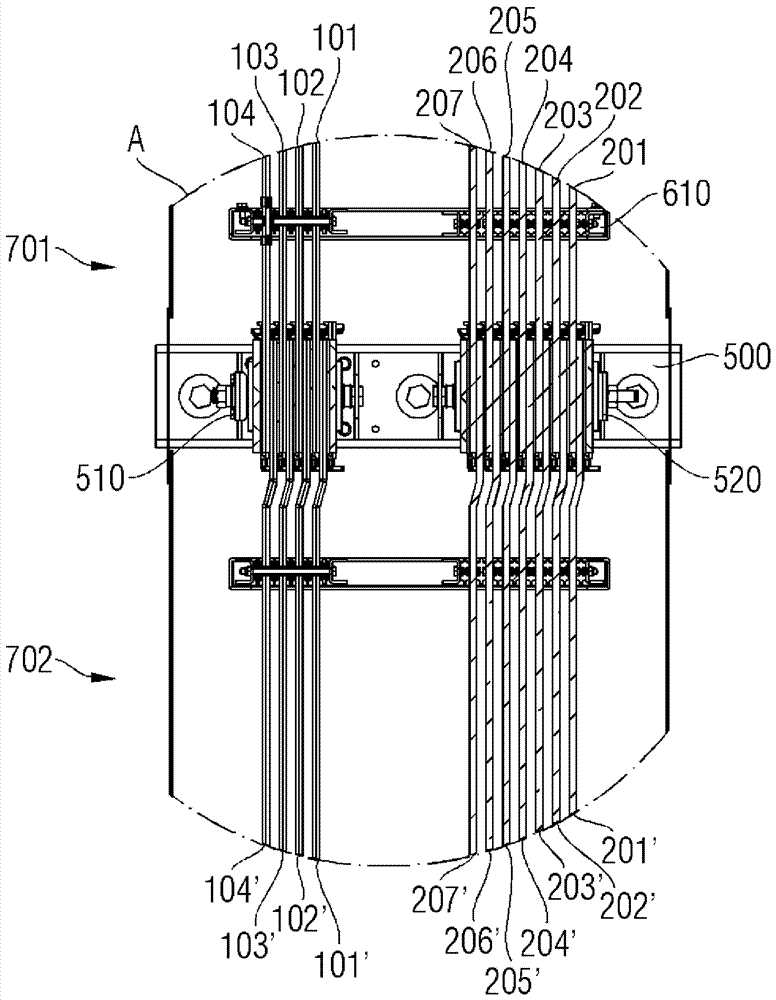

Busbar system

ActiveCN103378549ASave weight and materialLow costBus-bar/wiring layoutsTotally enclosed bus-bar installationsElectric energyBusbar

The invention relates to busbars having different cross sections for a busbar system with a common protection and / or neutral conductor for the transport of electrical energy, wherein the busbar system comprises at least one first segment and a second segment, the segments having each at least one first busbar with a first cross-sectional area, at least a second busbar with a second cross-sectional area, a holding element and at least one connection. According to the invention, the busbars of the segments are held by the respective holding element and are electrically connected to each other via the at least one connection, and a busbar from either the first busbars or second busbars serves as a common protection conductor (PE) and / or as a common neutral conductor.

Owner:SIEMENS AG

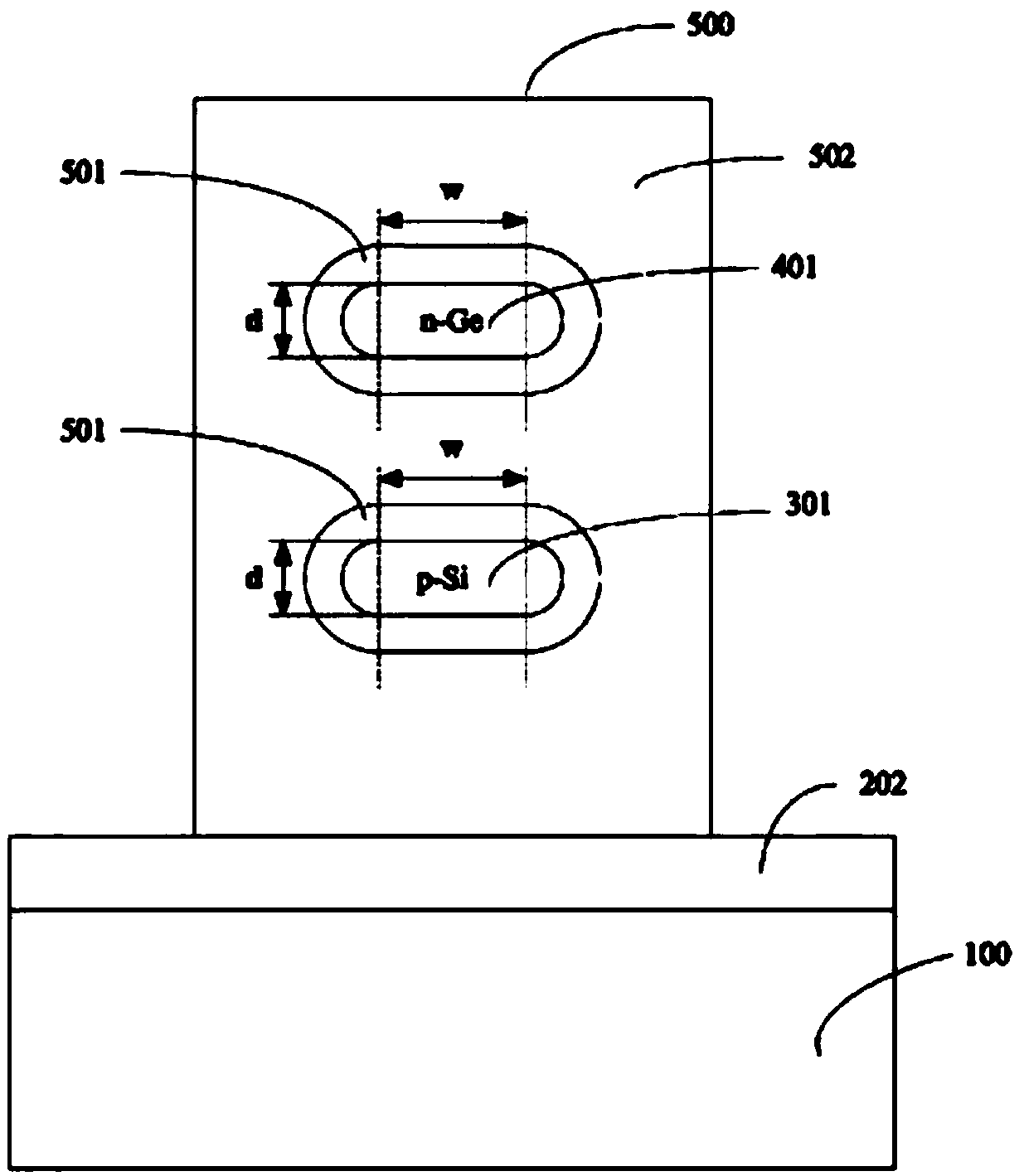

Semiconductor device structure and fabrication method thereof

ActiveCN109273441BReduce channel lengthHighly integratedTransistorNanoinformaticsGate dielectricDevice material

The invention provides a semiconductor device structure and a manufacturing method thereof. The structure includes: a substrate; a P-type semiconductor channel and an N-type semiconductor channel suspended on the substrate; a gate dielectric layer surrounding the P-type semiconductor channel and the N-type semiconductor channel. Semiconductor channel; gate electrode layer, surrounding the gate dielectric layer; P-type source region and P-type drain region, connected to both ends of the P-type semiconductor channel; N-type source region and N-type drain region, connected to the N-type semiconductor channel The two ends of the channel; wherein, the P-type ion doping concentration of the P-type semiconductor channel gradually decreases from the surface of the P-type semiconductor channel to the center, and the N-type ion doping concentration of the N-type semiconductor channel decreases from the N-type semiconductor channel. The surface of the channel gradually decreases toward the center, and the cross-sectional width of the P-type semiconductor channel is greater than that of the N-type semiconductor channel. The invention can realize multi-layer stacking of devices in a unit area, effectively shorten channel length, reduce short channel effect, and improve the load capacity of the device and the control ability of the gate to the channel.

Owner:SIEN QINGDAO INTEGRATED CIRCUITS CO LTD

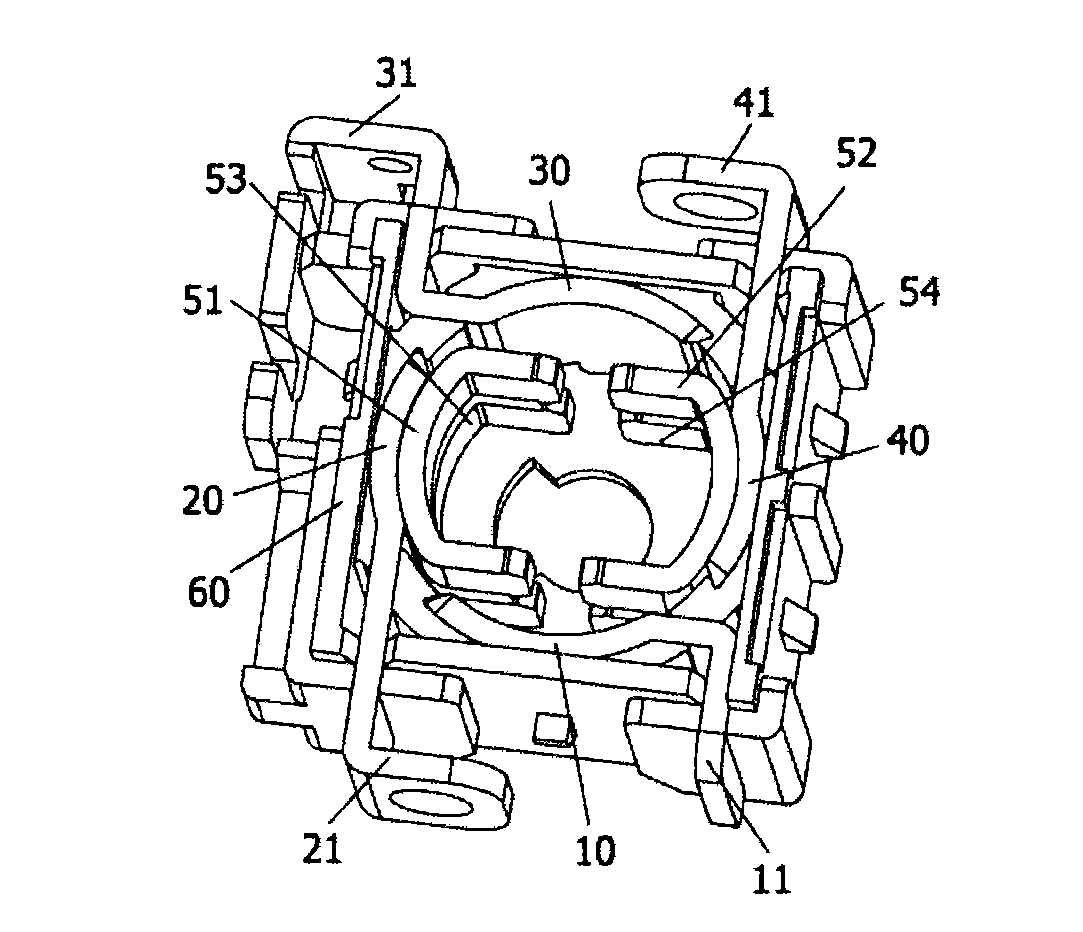

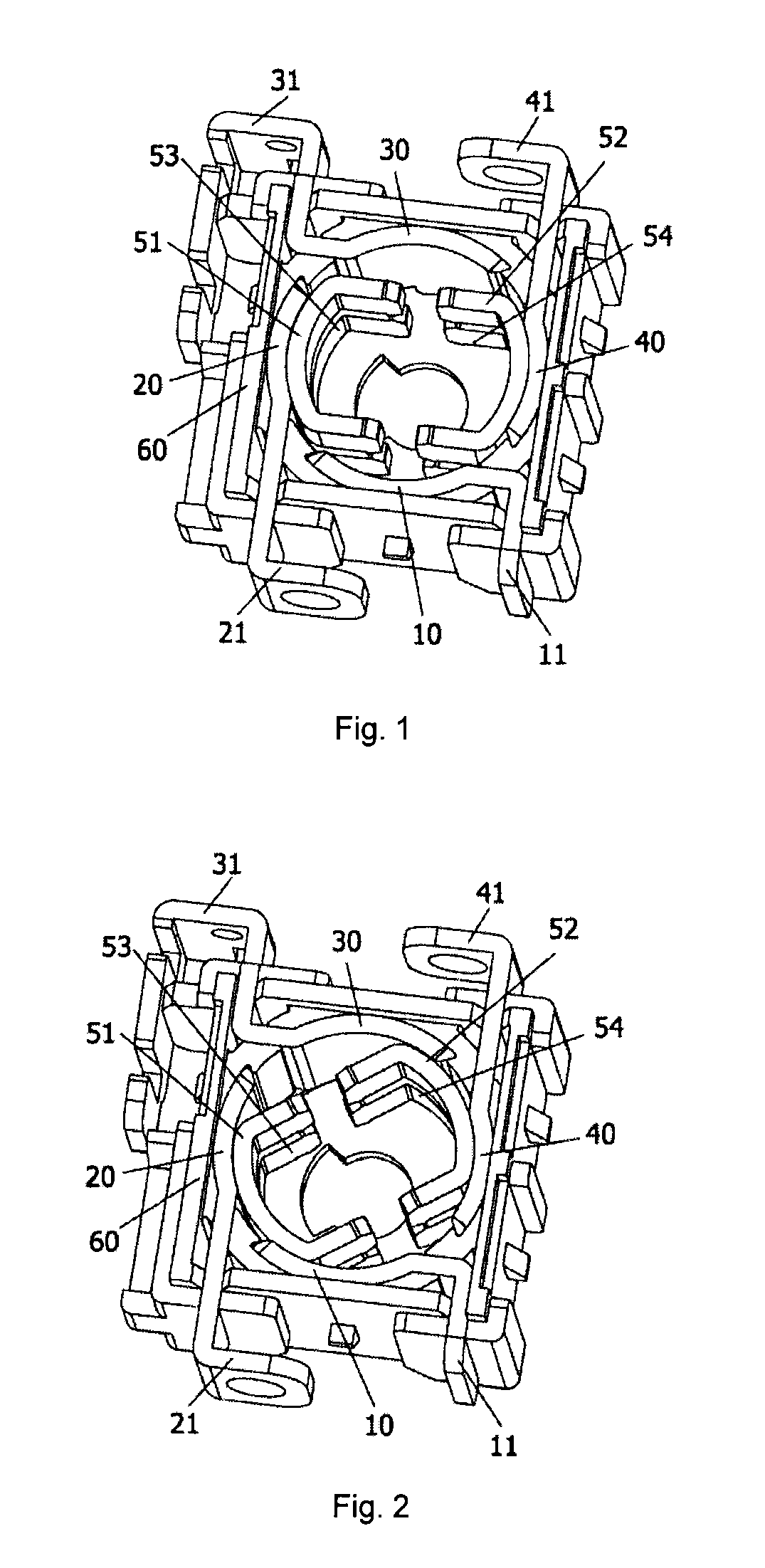

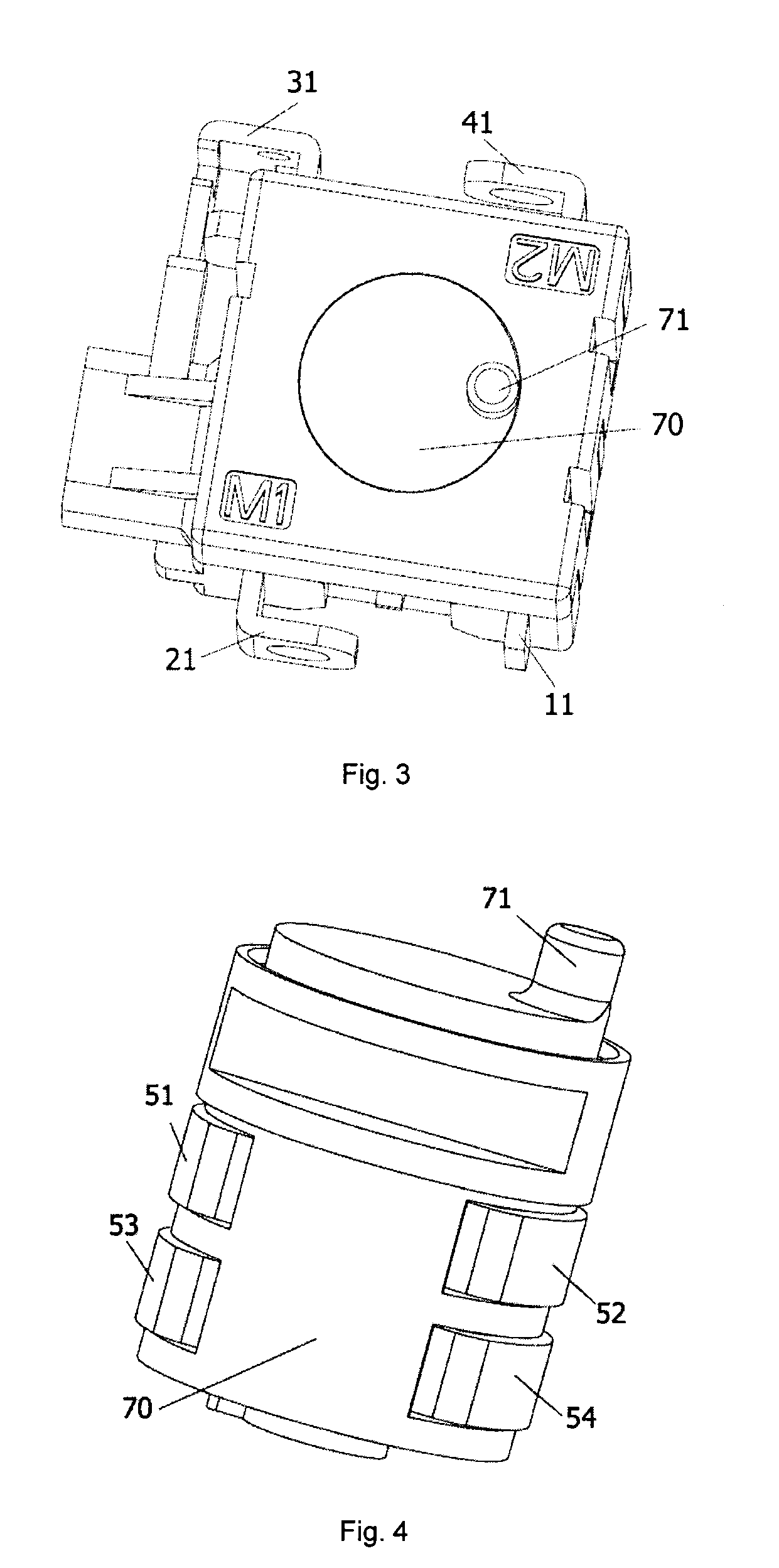

Reversing Switch

InactiveUS20150075955A1Internal resistance becomes largeEasy to produce heatContact electric connectionCurrent loadControl engineering

The present disclosure provides a reversing switch, including a switch body, and input terminals and output terminals independent from each other and provided in pairs on the switch body; each pair comprising one input terminal and one output terminal; wherein one of the input terminals is connected or disconnected with one of the output terminals via a plurality of independent reversing connectors, and the plurality of independent reversing connectors are configured to be movable synchronously. A plurality of independent reversing connectors are adopted between the input terminals and the output terminals of the reversing switch provided by the present disclosure to realize the connection and the disconnection between the input terminal and the output terminal, thus increasing the contact area between the reversing connectors and the input terminals or the output terminals, reducing the contact resistance, and improving the current loading capability of the reversing switch. In the meanwhile, the contact reliability could be ensured when the reversing switch is powered on because the number of contacts is increased, thereby effectively resisting the affection on the switch performance by shock and vibration.

Owner:SHANGHAI BAICHENG ELECTRONICS

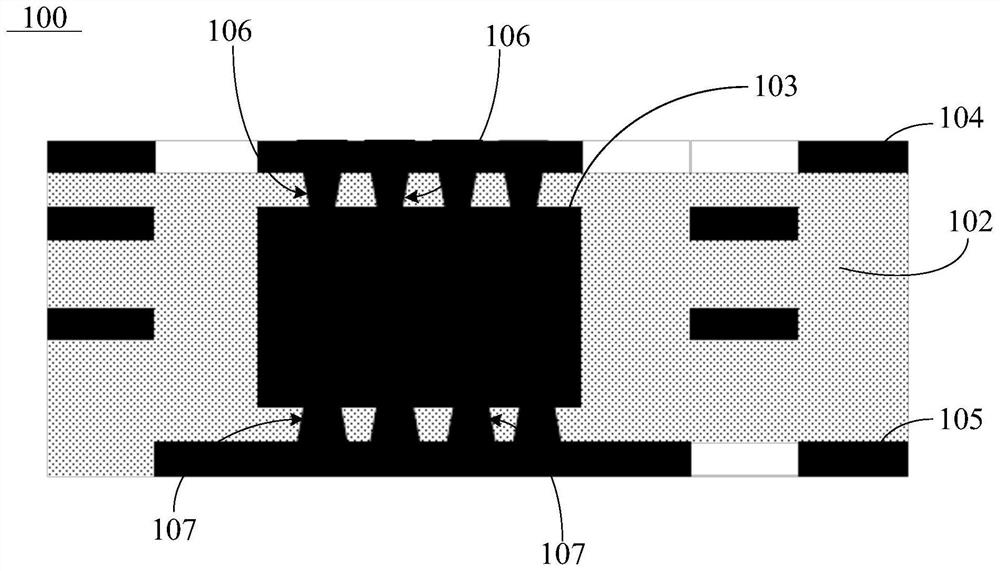

Current tolerance type multi-layer PCB and preparation method thereof

PendingCN113438832AIncreased current carrying capacityImprove cooling effectMultilayer circuit manufacturePrinted element electric connection formationEngineeringStructural engineering

The invention relates to a current tolerance type multi-layer PCB and a preparation method thereof. According to the preparation method, a plurality of inner-layer core plates and a plurality of prepregs are respectively subjected to through hole treatment, and then the through hole core plates and the through hole prepregs are stacked and arranged, so that through holes of the through hole core plates are communicated with through holes of the through hole prepregs. Then a conducting medium is placed into the communicated through holes, and first lamination treatment is performed to obtain a first laminated plate; and copper deposition and electroplating are performed on the first laminated plate to connect the conductive medium with the pre-arranged plate, secondary outer layer pattern processing is performed, secondary laminating treatment is performed, and the first copper foil and the second copper foil of the second laminated plate are respectively connected with the conductive medium through the first blind hole and the second blind hole. And then copper deposition treatment is carried out on the blind hole plate, and metal copper is attached to the hole walls of the first blind hole and the second blind hole. Through the preparation method, the current tolerance performance can be effectively improved.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

Hot melt welding agent

InactiveCN100519051CIncreased current carrying capacityImprove conductivityWelding/cutting media/materialsSoldering mediaElectrical conductorReaction temperature

Hot-melt solder belongs to a composition. The prior art cannot fully weld metals, fail to achieve intermetallic molecular bonding, and the mechanical strength and electrical conductivity are not ideal. The present invention is composed of the following powdery components and corresponding mass percentages: Composition: copper oxide 58%~62%, iron oxide 4%~6%, aluminum 4%~6%, magnesium 14%~16%, copper 6%~8%, iron 1%~3%, phosphorus 4%~ 6%. The invention can be used for welding between pure copper, brass, bronze, red copper, copper-clad steel, pure iron, stainless steel, wrought iron, galvanized steel, cast iron, etc. Good performance, stable impact resistance, strong corrosion resistance, simple and safe connection, different reaction temperatures can be configured according to the metal characteristics of the conductor to be welded, so that the welded joint is stronger and more perfect.

Owner:ZHEJIANG HUADIAN LIGHTENING PROTECTION TECHCO

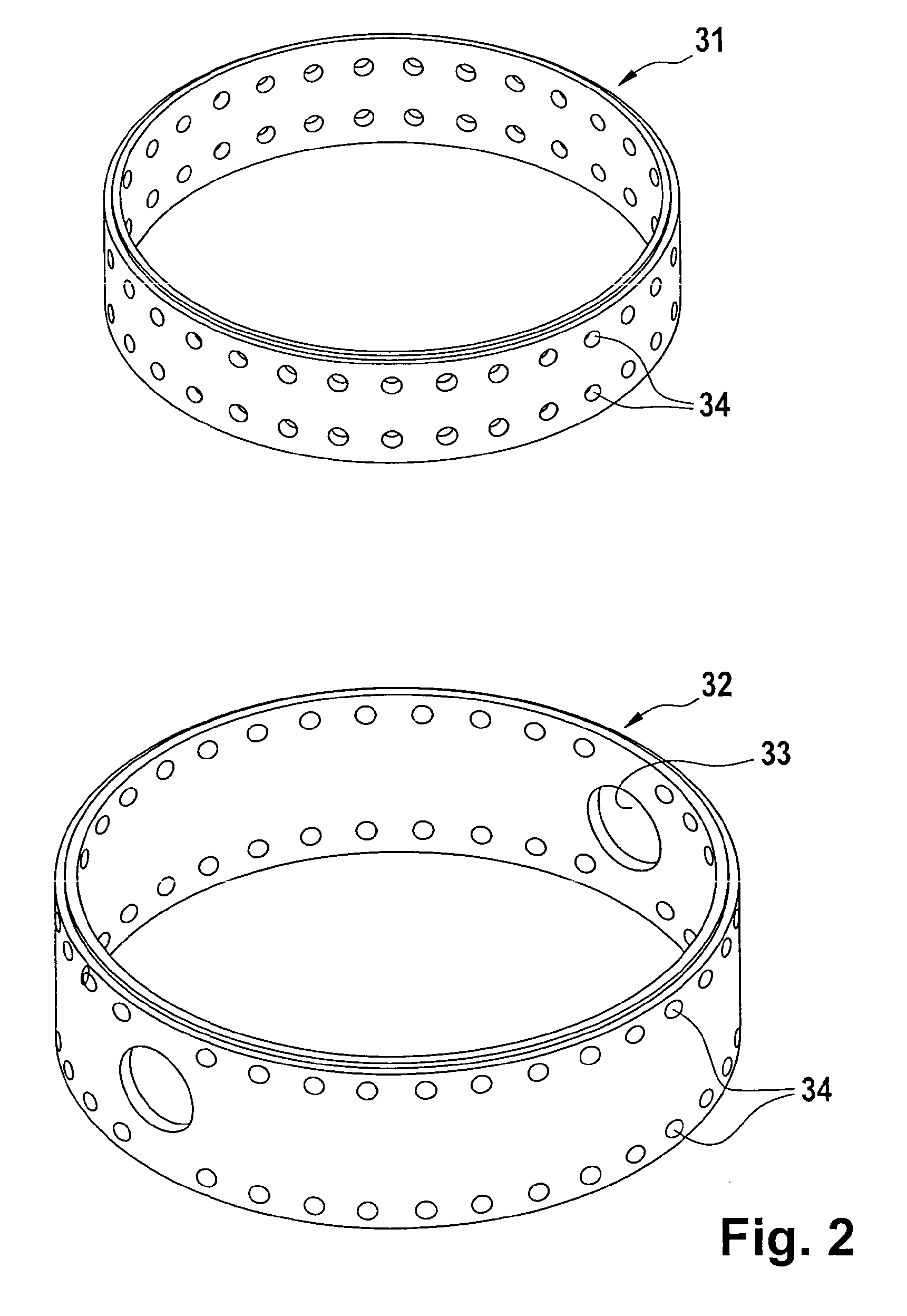

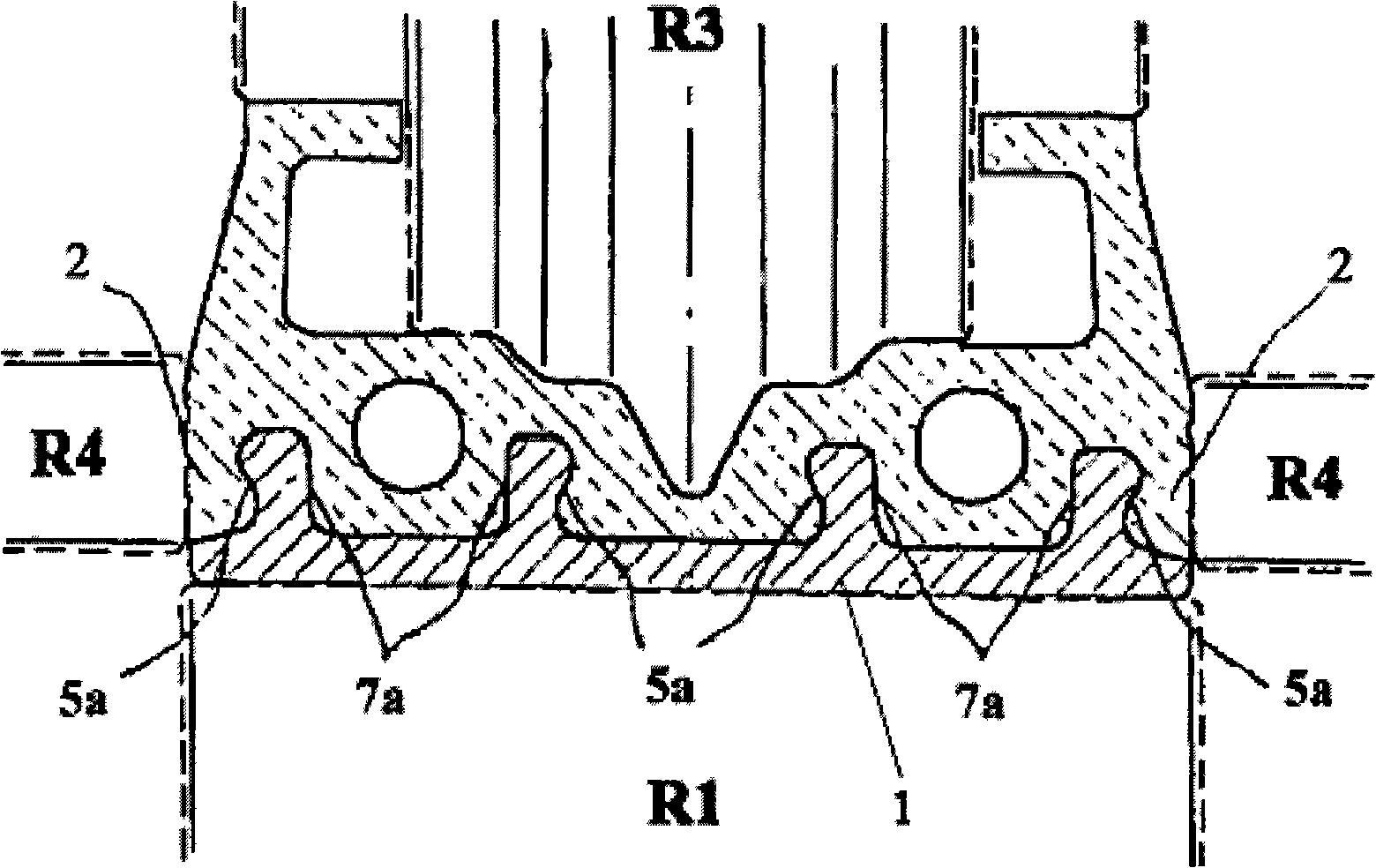

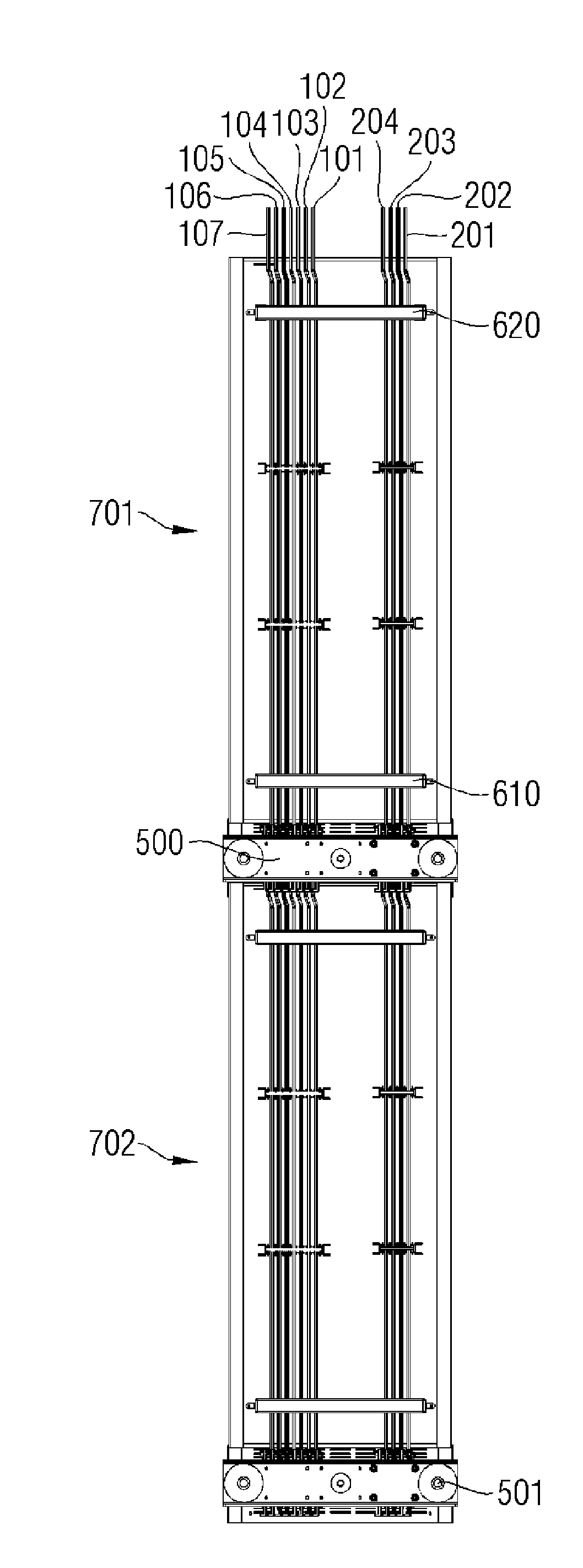

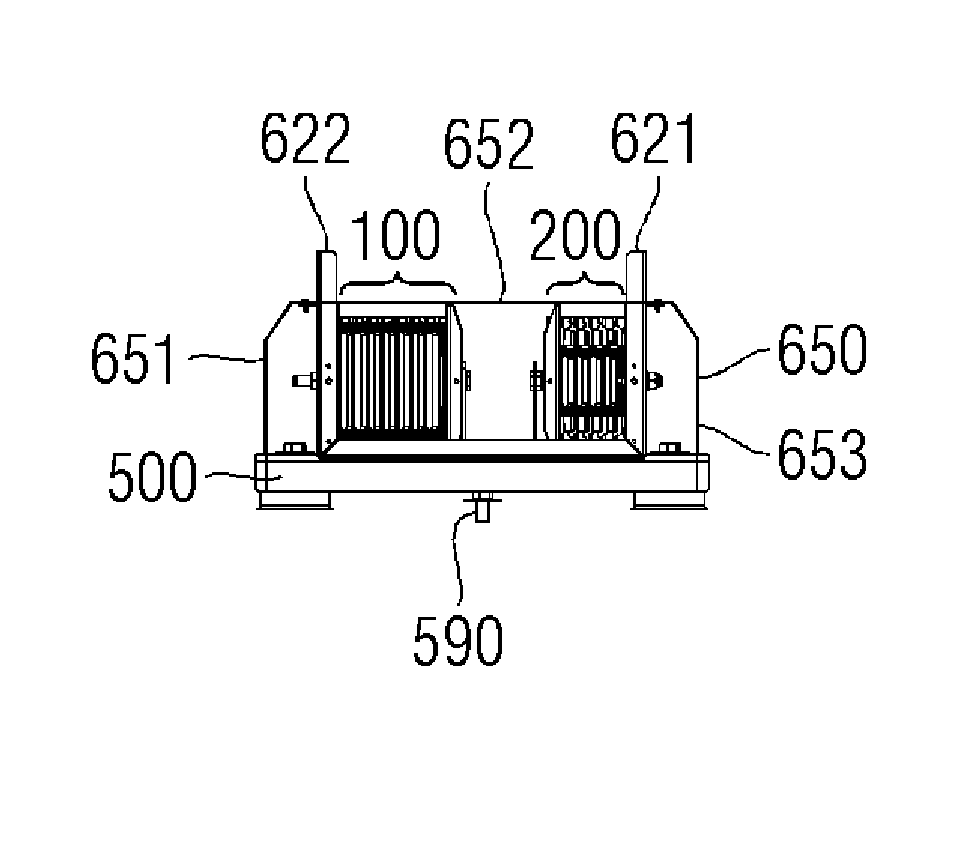

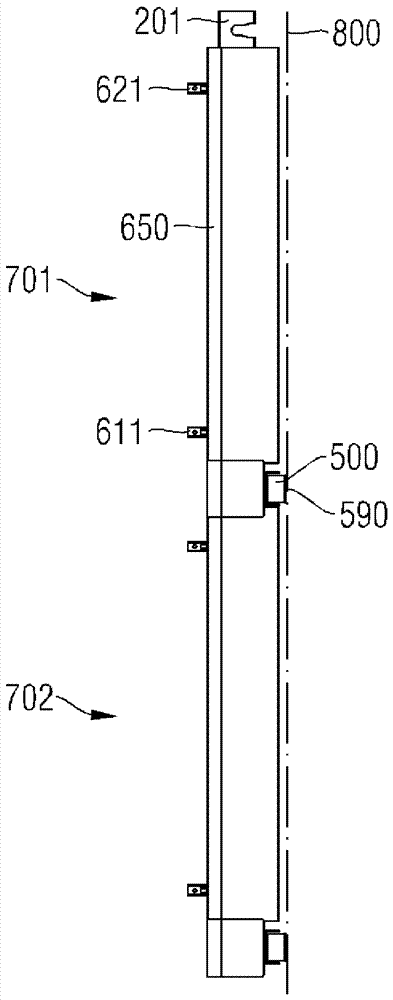

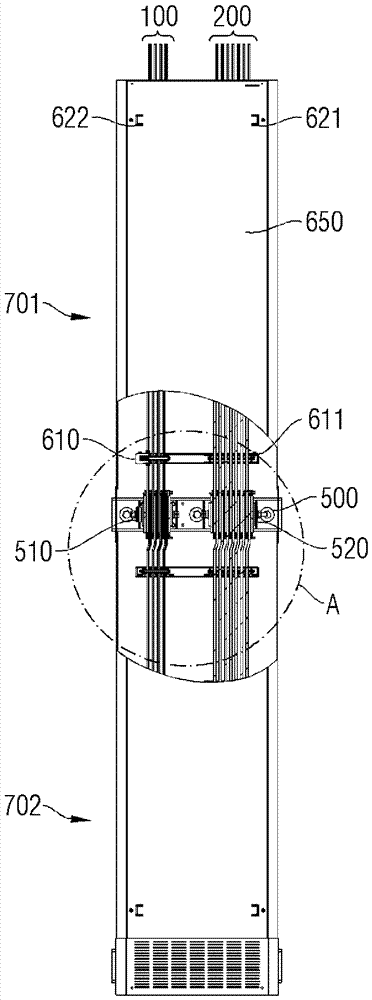

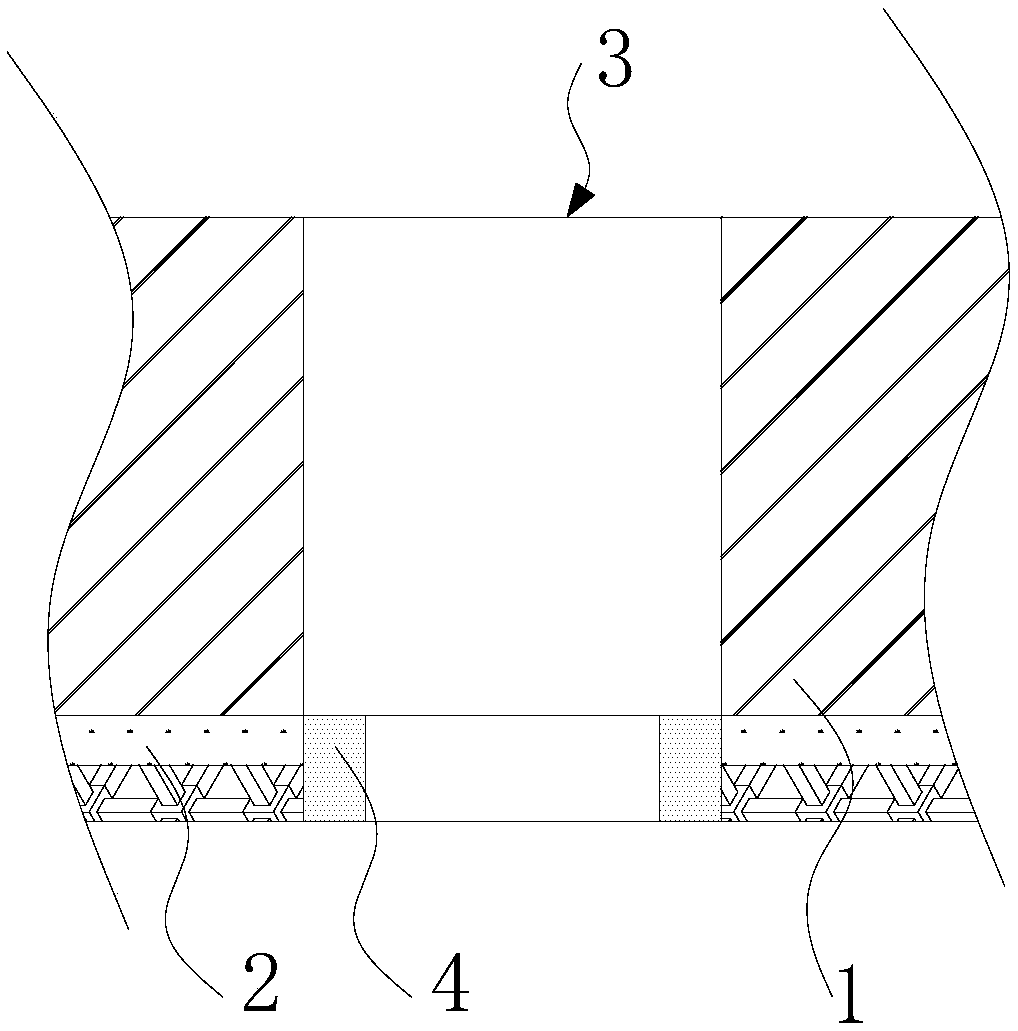

busbar system

ActiveCN103259229BIncreased current carrying capacityImprove cooling effectTotally enclosed bus-bar installationsWind energy generationBusbarElectrical connection

A busbar system for conveying electrical energy is disclosed, wherein the busbar system comprises at least a first segment and a second segment, wherein the segments each comprise at least one first busbar having a first cross-section and holders, wherein the busbars of the segments are held by corresponding holders and are electrically connected to each other through connection mechanisms.

Owner:SIEMENS AG

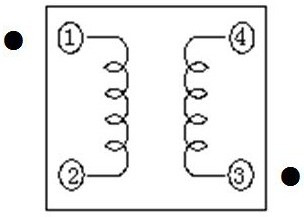

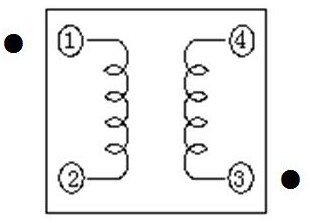

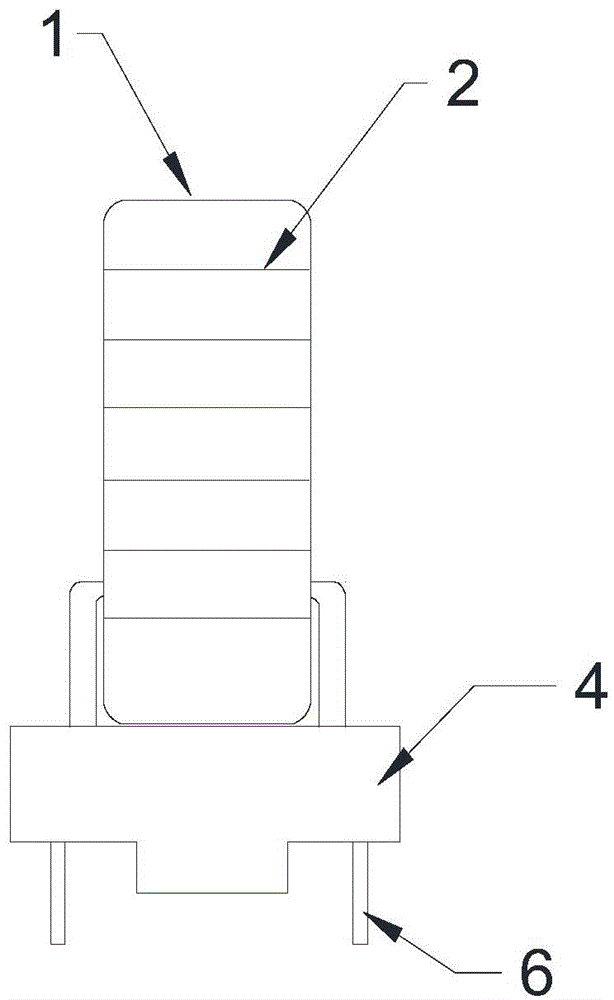

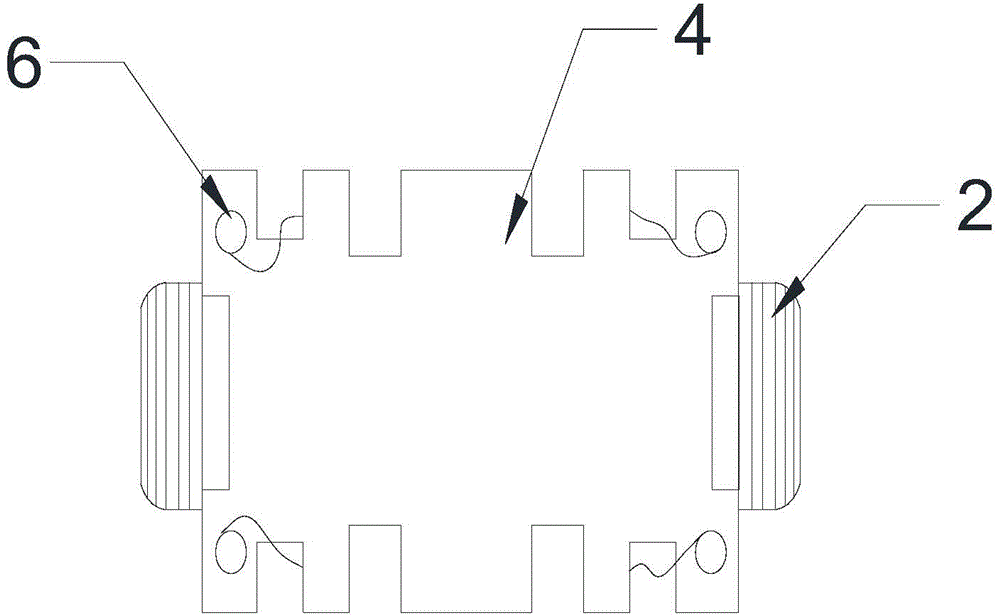

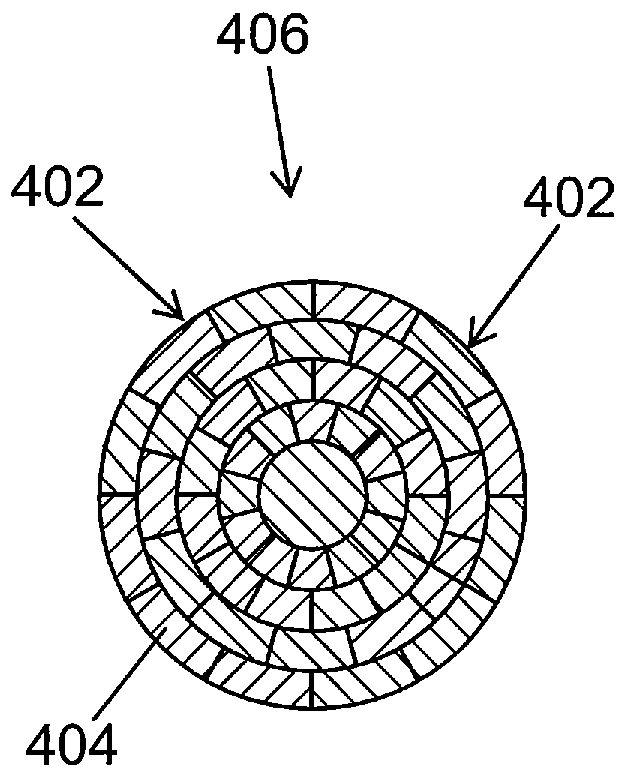

Large current common mode filter coil

InactiveCN104409199APracticalIncreased current carrying capacityTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionMagnetic coreEngineering

The invention relates to a current filter device, and in particular relates to a large current common mode filter coil. The large current common mode filter coil comprises a round magnetic core, two strands of wires are wound on the magnetic core and two strands of wires are isolated through an insulation plate; the large current common mode filter coil further comprises a base, the upper surface of the base is provided with a bracket, the surface of which is cambered surface, pins are formed at four peaks of the lower surface of the base, two ends of the wire are connected with two pins being parallel to the axial direction line of the connection line and the round magnetic core, the large current common mode filter coil further comprises a guide slot formed on one side of the base being parallel to the plane of the axial direction of the round magnetic core; the large current common mode filter coil has larger current load capability, uses the filter function for increasing the service life under the large current work state and has practicability.

Owner:CHANGZHOU GALAXY INNOVATION MAGNETOELECTRICITY

Semiconductor device structure and fabrication method thereof

ActiveCN109244072BReduce channel lengthHighly integratedTransistorSolid-state devicesGate dielectricDevice material

The invention provides a semiconductor device structure and a manufacturing method thereof. The semiconductor device structure includes: a substrate; a P-type semiconductor channel suspended above the substrate; an N-type semiconductor channel suspended above the substrate The gate dielectric layer is surrounded by the P-type semiconductor channel and the N-type semiconductor channel; the gate electrode layer is surrounded by the gate dielectric layer; the P-type source region and the P-type drain region are respectively connected to the The two ends of the P-type semiconductor channel; and the N-type source region and the N-type drain region are respectively connected to the two ends of the N-type semiconductor channel; wherein, the cross-sectional width of the P-type semiconductor channel is greater than that of the N Type semiconductor channel cross-sectional width. The invention can realize multi-layer stacking of devices in a unit area, effectively shorten the channel length of the device, reduce the short channel effect, improve the load capacity of the device, and effectively improve the integration degree of the device.

Owner:SIEN QINGDAO INTEGRATED CIRCUITS CO LTD

Busbar system

ActiveCN103259229AIncreased current carrying capacityImprove cooling effectTotally enclosed bus-bar installationsWind energy generationBusbarElectrical connection

A busbar system for the transport of energy especially for long vertical paths is disclosed, wherein the busbar system comprises multiple sections, the sections each comprise multiple busbars and a holding piece, and the busbars of the sections are held by the respective holding pieces and electrically connected to one another via a connection.

Owner:SIEMENS AG

Semiconductor device structure and manufacturing method thereof

ActiveCN109300896AReduce channel lengthHighly integratedTransistorNanoinformaticsEngineeringMedia layer

The invention provides a semiconductor device structure and a manufacturing method thereof. The semiconductor device structure comprises a substrate, a P type semiconductor channel, an N type semiconductor channel, a gate medium layer, a gate electrode layer, P source and drain regions and N source and drain regions; the P type semiconductor channel is hung over the substrate, and a silicon-tritium passivation layer is formed in the surface of the P type semiconductor channel; the N type semiconductor channel is hung over the substrate, and a silicon-tritium passivation layer is formed in thesurface of the N type semiconductor channel; the gate medium layer surrounds the P type semiconductor channel and the N type semiconductor channel; the gate electrode layer surrounds the gate medium layer; the P source and drain regions are connected to the two ends of the P type semiconductor channel respectively; the N source and drain regions are connected to the two ends of the N type semiconductor channel; and the width of the cross section of the P type semiconductor channel is greater than that of the cross section of the N type semiconductor channel. Multiple layers of the device can be laminated in the unit area, the channel length of the device can be reduced effectively, the short channel effect can be reduced, the load capacity of the device is improved, and the integrated level and reliability of the device are improved.

Owner:SIEN QINGDAO INTEGRATED CIRCUITS CO LTD

busbar system

ActiveCN103378549BIncreased current carrying capacityLow costBus-bar/wiring layoutsTotally enclosed bus-bar installationsBusbarElectrical connection

Owner:SIEMENS AG

Laser-double tig arc composite self-fusion brazing method of aluminum alloy and stainless steel

ActiveCN113427132BAvoid disadvantagesImprove energy utilizationLaser beam welding apparatusLap jointLaser beams

A laser-double TIG arc composite self-melting brazing method for aluminum alloy and stainless steel, including using laser beam-double TIG arc composite heat source to weld the lap joint where the aluminum alloy plate is on the top and the stainless steel is on the bottom, and the composite heat source melts the aluminum alloy , heating the stainless steel to form a brazing interface. The laser beam is a scanning laser beam with variable power pulse; the double TIG electric arc includes a positive polarity TIG electric arc and a reverse polarity TIG electric arc; side; during the welding process, the laser beam scans the surface of the workpiece to be welded, and ensures that 2 / 3-3 / 4 of the laser heat is on the aluminum alloy plate, 1 / 3-1 / 4 of the laser heat is on the stainless steel plate, and the DC is reversed to TIG The welding torch and DC positive TIG welding torch alternately start the arc, the reverse polarity TIG arc and high-power laser pulse form a composite heat source, and the positive polarity TIG arc and low-power laser pulse form a composite heat source. The welding method of the invention can obtain self-fluxing brazing joints with excellent mechanical properties.

Owner:GUANGDONG CSR RAIL TRAFFIC VEHICLE CO LTD

high voltage transmission line

InactiveCN106856666BIncrease the cross-sectional areaShorten the lengthCable installations on groundCable installations in underground tubesElectrical conductorMechanical engineering

A HV power transmission line (106) with at least two tubular electrical insulation devices (108), at least one electrically uninsulated nominal conductor segment (102) and a joint (1 17) for jointing the ends of the insulation devices plus at least one power termination (109) for connecting the transmission line. The insulation device (108) is flexible, has an inner electrically conductive layer (1 10) at its inner wall surface, and is of such insulation quality that it can electrically insulate the conductor segment (102) from the exterior of the insulation device once inserted into the tubular insulation device. Once inserted the uninsulated conductor segment touches the inner electrically conductive layer (1 10) at an inner wall surface of the tubular electrical insulation device such that the inner electrically conductive layer (1 10) is on the same electric potential as the conductor segment in an operating state of the HV power transmission line each.

Owner:ABB (SCHWEIZ) AG

Laser power supply circuit board and preparation method thereof

InactiveCN108966484AIncreased current carrying capacityAvoid damagePrinted circuit assemblingPrinted circuit aspectsElectrical resistance and conductanceEngineering

The invention provides a laser power supply circuit board and a preparation method thereof. The circuit of a PCB bare board is provided with a soldering tin hole and mounting holes for mounting components. The soldering tin hole is internally provided with a pad. In preparation of the laser power supply circuit board, components are inserted into the mounting holes, and then the components are welded in a wave soldering manner. The soldering tin hole of the prepared laser power supply circuit board is filled with soldering tin. According to the laser power supply circuit board prepared according to the preparation method, the soldering tin hole is filled with the soldering tin; and the circuit part with the soldering tin hole has a large current flowing channel and small resistance, and therefore damage of the circuit caused by overheat because of overhigh current can be prevented. The soldering tin hole is arranged on the circuit board in advance, and the soldering tin is applied to the soldering tin hole in soldering each component through wave soldering, thereby realizing no requirement for other labor for filling the soldering tin hole, and realizing simple and convenient manufacturing process of the laser power supply circuit board.

Owner:临沂朝日电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com