Laser-double tig arc composite self-fusion brazing method of aluminum alloy and stainless steel

A brazing method and stainless steel technology, which is applied in the field of welding processing, can solve problems such as uneven interface layers, and achieve the effects of improving weld quality, improving weld shape, and lower temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

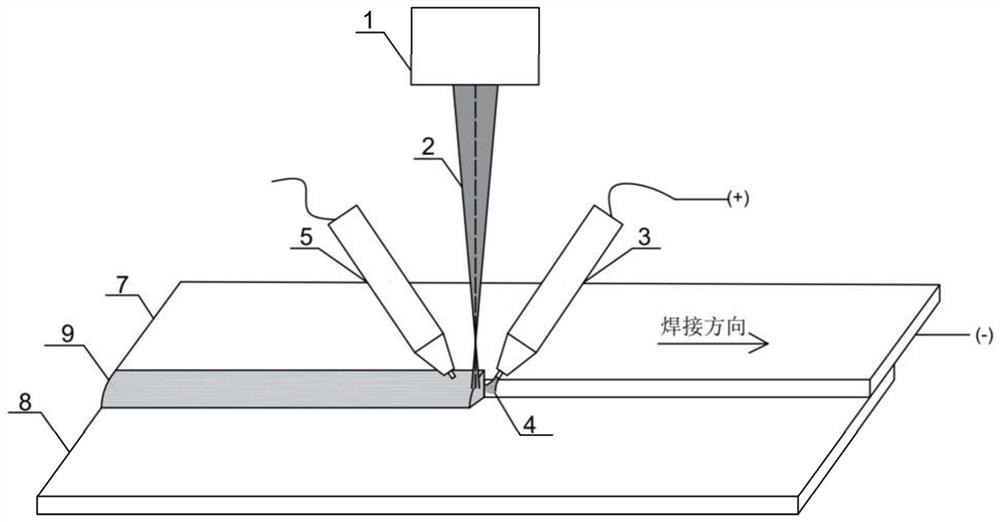

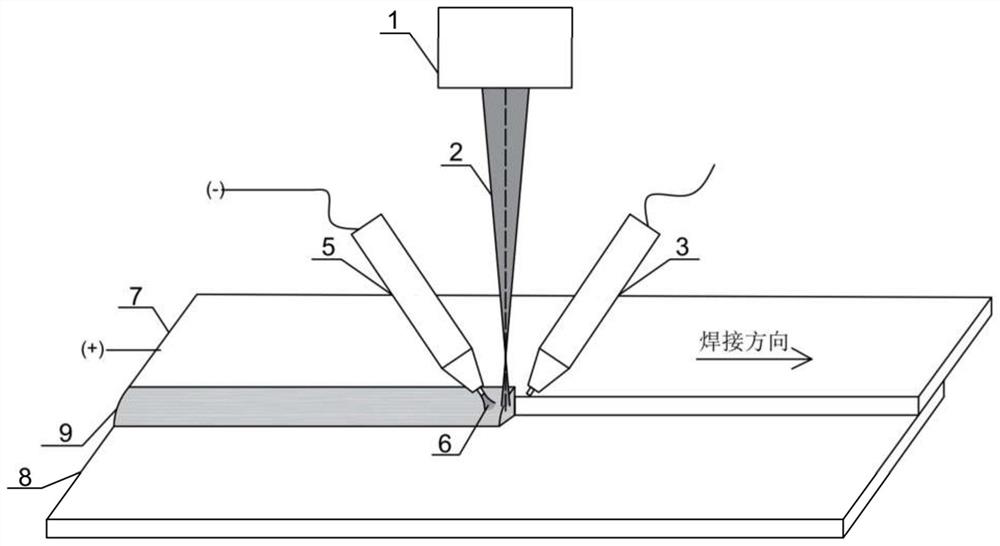

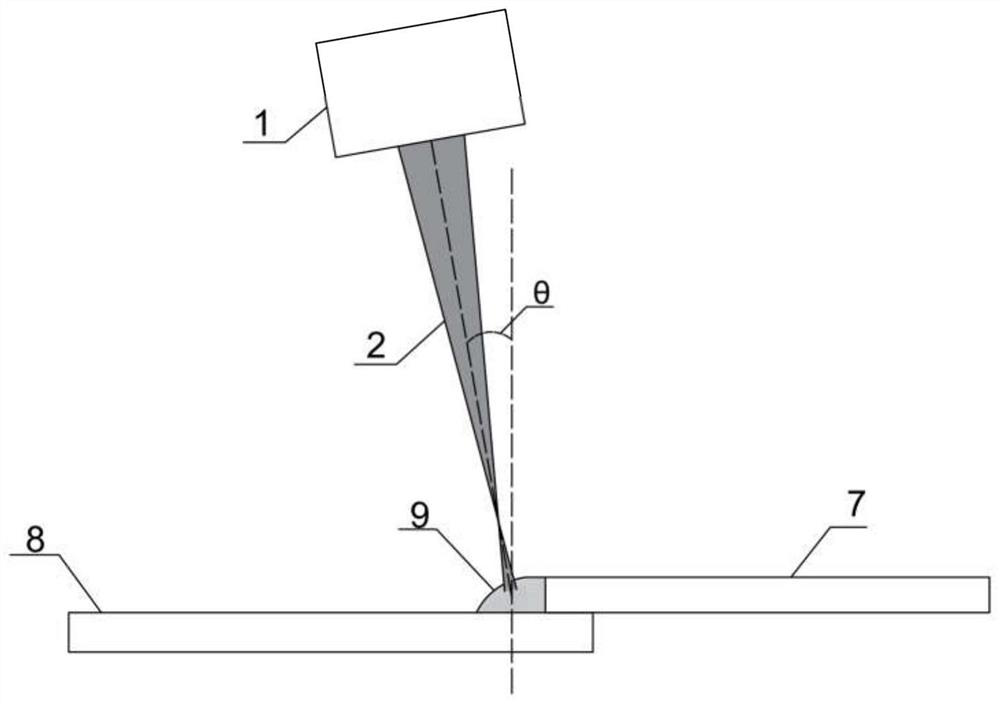

[0053] A laser-double TIG arc composite self-fluxing brazing method for aluminum alloy and stainless steel, the aluminum alloy plate to be welded is a 6061 aluminum alloy plate with a thickness of 2mm, and the stainless steel plate to be welded is a 301L stainless steel plate with a thickness of 2mm , the self-melting brazing method includes cleaning and pretreatment of the area to be welded and the surrounding area of the aluminum alloy plate and the stainless steel plate to be welded, assembling the stainless steel plate and the aluminum alloy plate into a lap joint form in which the aluminum alloy plate is on top and the stainless steel is on the bottom, The connecting distance is set to 10mm to form the workpiece to be welded;

[0054] Laser beam-double TIG arc composite heat source is used to weld the workpiece to be welded. The composite heat source melts the aluminum alloy and heats but does not melt the stainless steel; the molten aluminum alloy spreads on the unmelte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com