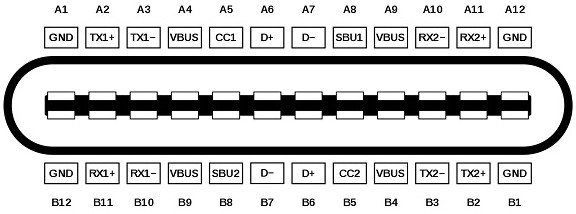

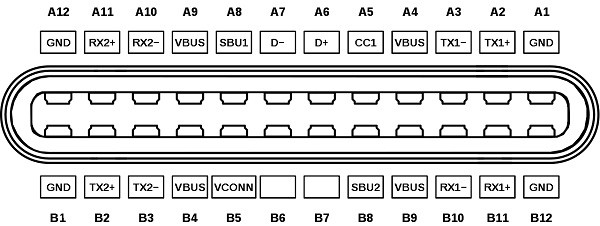

Type-C male end connector adopting non-porous PCB

A technology of PCB boards and connectors, which is applied in the direction of connection, fixed connection, and electrical connection of printed components. It can solve the problems of poor current passing capacity, small via holes, and increased costs, so as to improve current load capacity, reduce design size, The effect of electrical connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment is used to illustrate the application of the Type-C male connector provided by the present invention using a non-hole PCB board to a Type-C common cable.

[0043] Among them, the PCB board will be connected at the end of the cable so that the terminals and the core wires of the cable are connected correspondingly, and injection molding will be performed on the back section of the metal shell to package the Type-C male connector and the cable together. This part sets It is the same as the prior art, so it will not be illustrated and described in detail.

[0044] In this example, if Figure 11 As shown, the terminals used to realize the electrical connection of the power supply GND and the power supply VBUS are all made of common mode double-ended double-pin PIN pin 31, and its structure is as follows Figure 7 shown. The front end of the double-ended double-leg PIN needle 31 has two fork-shaped terminals 311 arranged up and down side by side in a fork s...

Embodiment 2

[0047] This embodiment is used to illustrate the application of the Type-C male connector provided by the present invention using a non-hole PCB board in a Type-C active cable packaged with an E-Marker chip.

[0048] Among them, the PCB board will be connected at the end of the cable so that the terminals and the core wires of the cable are connected correspondingly, and injection molding will be performed on the back section of the metal shell to package the Type-C male connector and the cable together. This part sets It is the same as the prior art, so it will not be illustrated and described in detail.

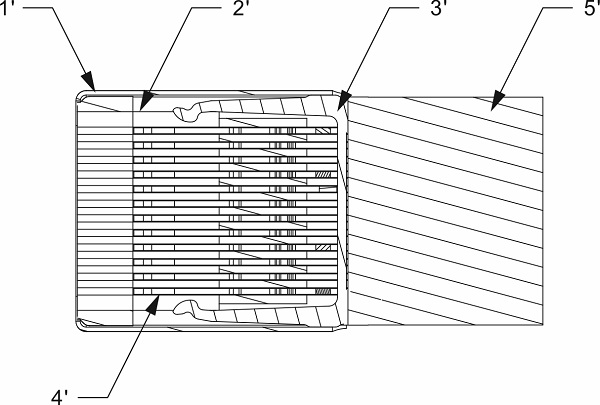

[0049] like Figure 13 As shown, at least one single-ended double-pin PIN needle 31' is also configured in the terminal, which is used to realize the chip connection when the E-MARK chip 6 is packaged on the PCB board 5; the rear end of the single-ended double-pin PIN needle 31' There are two fork-shaped connecting feet 312' arranged side by side up and down in a fork shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com