Small-diameter and high-power flexible heating cable and preparation method thereof

A heating cable, high-power technology, applied in the direction of heating element material, heating element shape, etc., can solve the problems of unsatisfactory working effect, inconvenient use and installation, large size and other problems, achieve good processability, improve work efficiency, Effect of High Current Carrying Capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

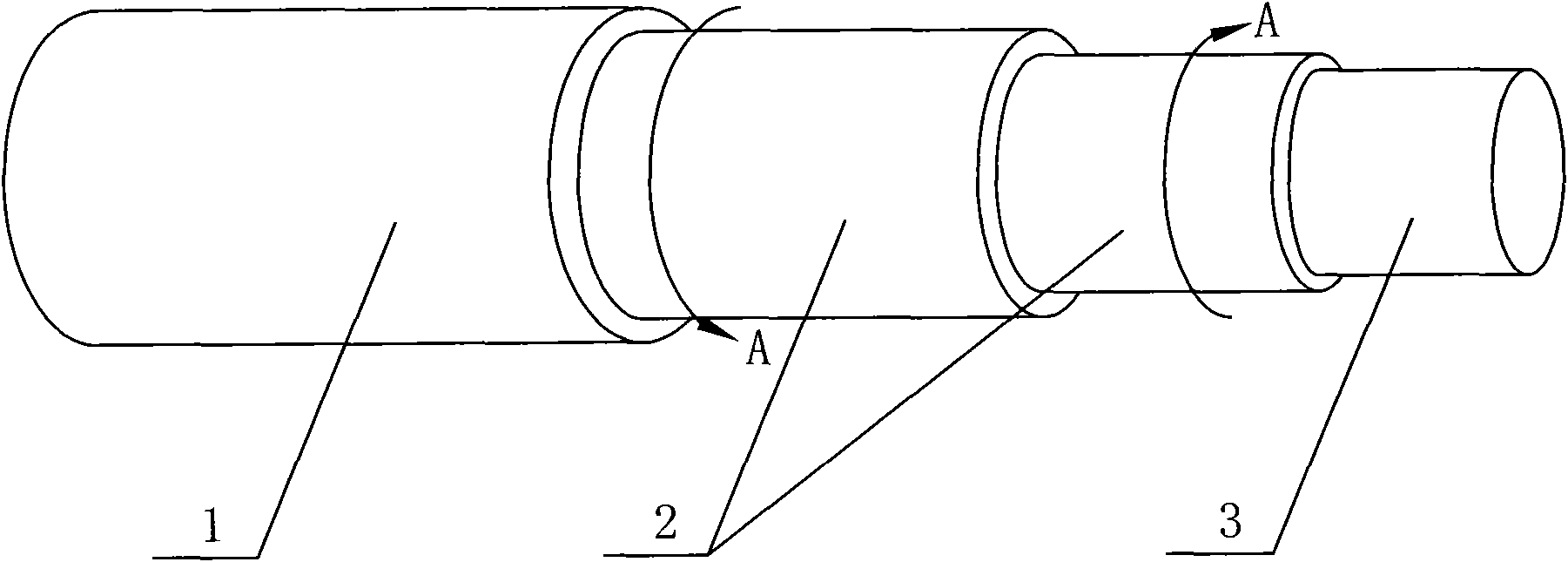

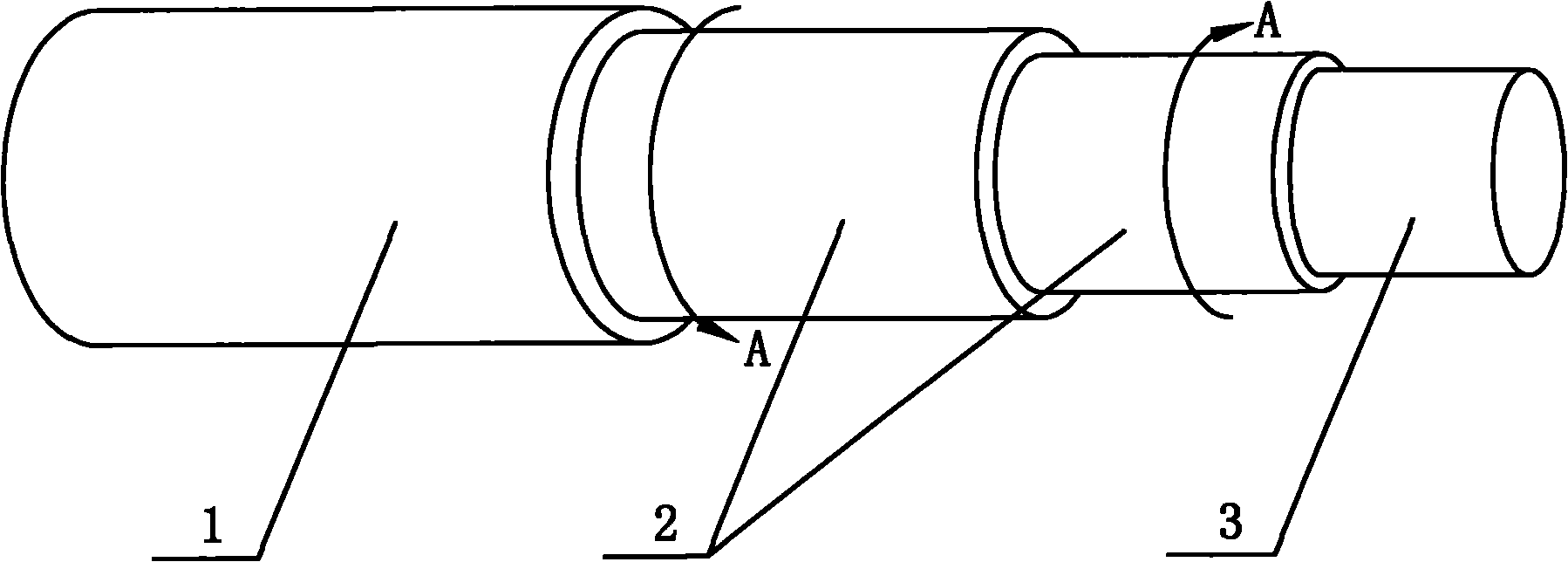

[0027] see figure 1 , a small-diameter high-power flexible heating cable, characterized in that: the innermost layer of the small-diameter high-power flexible heating cable is a heating alloy wire core wire 3; the outer heating alloy wire core wire 3 is wrapped with at least Two layers of insulating fiber layers 2 are coated with a high-temperature-resistant bonding and sealing coating layer 1 on the outside of the insulating fiber layers 2 .

[0028] The wrapping directions of the two adjacent insulating fiber layers 2 are opposite. see figure 1 Middle wrapping direction A.

[0029] The diameter of the heating alloy wire core wire 3 is 0.5 mm; the heating alloy wire core wire 3 is 0Cr27Al7Mo2 alloy with a resistivity of 1.53 μΩ.m.

[0030] The layer of insulating fiber layer 2 is made of monofilament diameter of 5 μm, SiO 2 It is wrapped with high-purity fine quartz fibers with a content ≥99.95%.

[0031] The high-temperature-resistant bonding and sealing coating layer 1...

Embodiment 2

[0039] Others are the same as in Example 1, the diameter of the heating alloy wire core wire 3 is 0.5 mm; the alloy is a 6J22 alloy with a resistivity of 1.33 μΩ.m;

[0040] The layer of insulating fiber layer 2 is made of monofilament diameter of 6 μm, SiO 2 It is wrapped with high-purity micro-fine quartz fibers with a content ≥99.95%;

[0041] The winding speed voltage in the step b is 60V;

[0042] The spraying pressure in the step c is 0.5 MPa.

Embodiment 3

[0044] Others are the same as in Example 1, the diameter of the heating alloy wire core wire 3 is 0.5 mm; the alloy is a 1Cr20Al3 alloy with a resistivity of 1.23 μΩ.m;

[0045] The layer of insulating fiber layer 2 is made of monofilament diameter of 5 μm, SiO 2 It is wrapped with high-purity micro-fine quartz fibers with a content ≥99.95%;

[0046] The winding speed voltage in the step b is 80V;

[0047] The spraying pressure in the step c is 0.3 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com