LED lamp band circuit board module containing multifunctional aluminum foil, and manufacturing method

A technology of LED light strips and circuit boards, which is applied to printed circuits, printed circuits, circuit heating devices, etc., and can solve problems such as low efficiency, high cost, and short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below by taking preferred embodiments as examples.

[0032] However, those skilled in the art should understand that the following descriptions are only examples and descriptions of some preferred implementations, and do not have any limitations on the claims of the present invention.

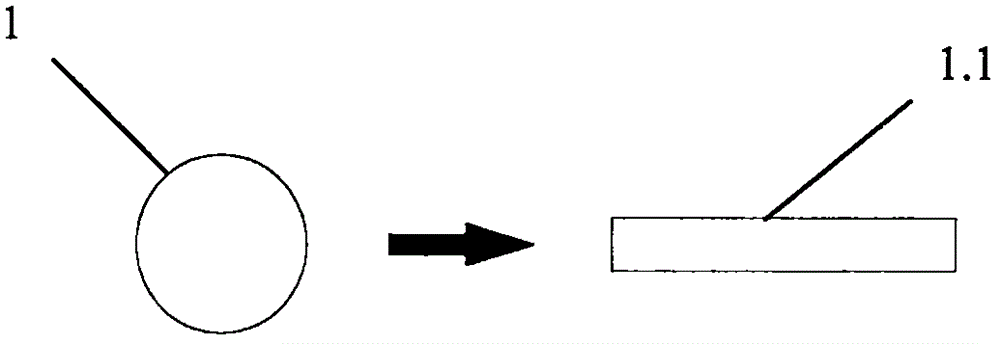

[0033] 1. The production of the top line: such as figure 1 As shown, the round copper-clad aluminum wire (1) is rolled into a flat wire with a certain width and thickness with a calender to make a back wire (1.1) whose surface is copper.

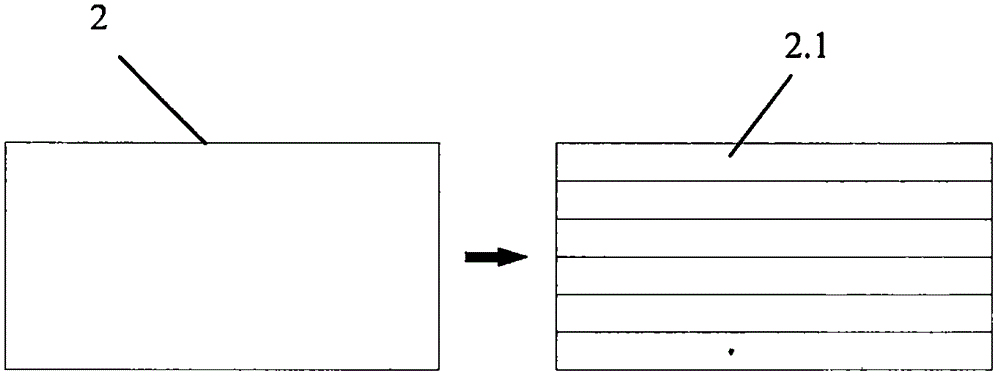

[0034] 2. Production of aluminum foil that acts as a conductive, thermally conductive, and protective layer: such as figure 2 As shown, the aluminum foil (2) is cut into strips with a slitting machine to make a plurality of aluminum foil strips (2.1) whose width is larger than that of the back line (1.1).

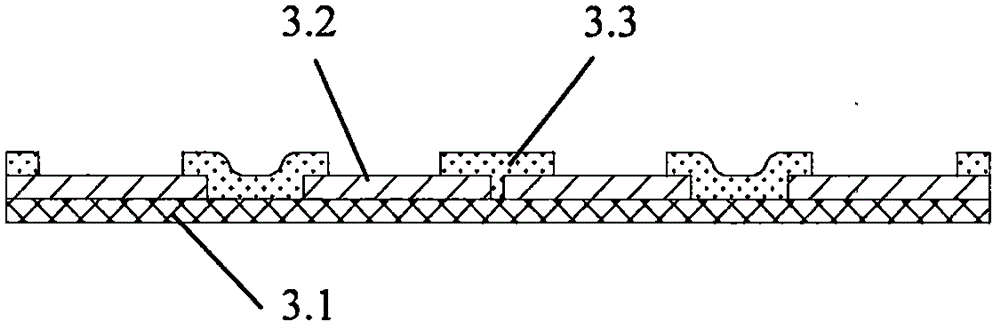

[0035] 3. Production of single-sided flexible circuit board: single-sided PCB production proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com