high voltage transmission line

A high-voltage transmission line and voltage technology, which is applied in the installation of electrical components, cables, ground cables, etc., can solve the problems of long-term electrical reliability reduction and installation time extension, and achieve the effect of reducing required space and production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

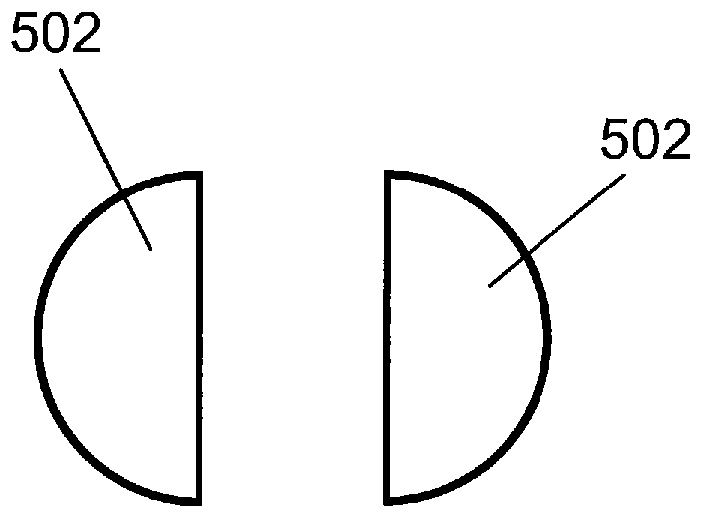

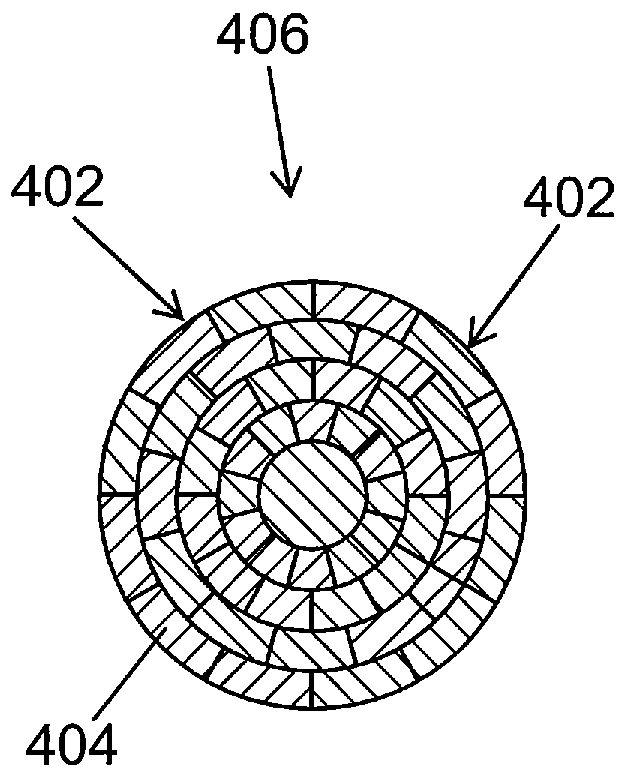

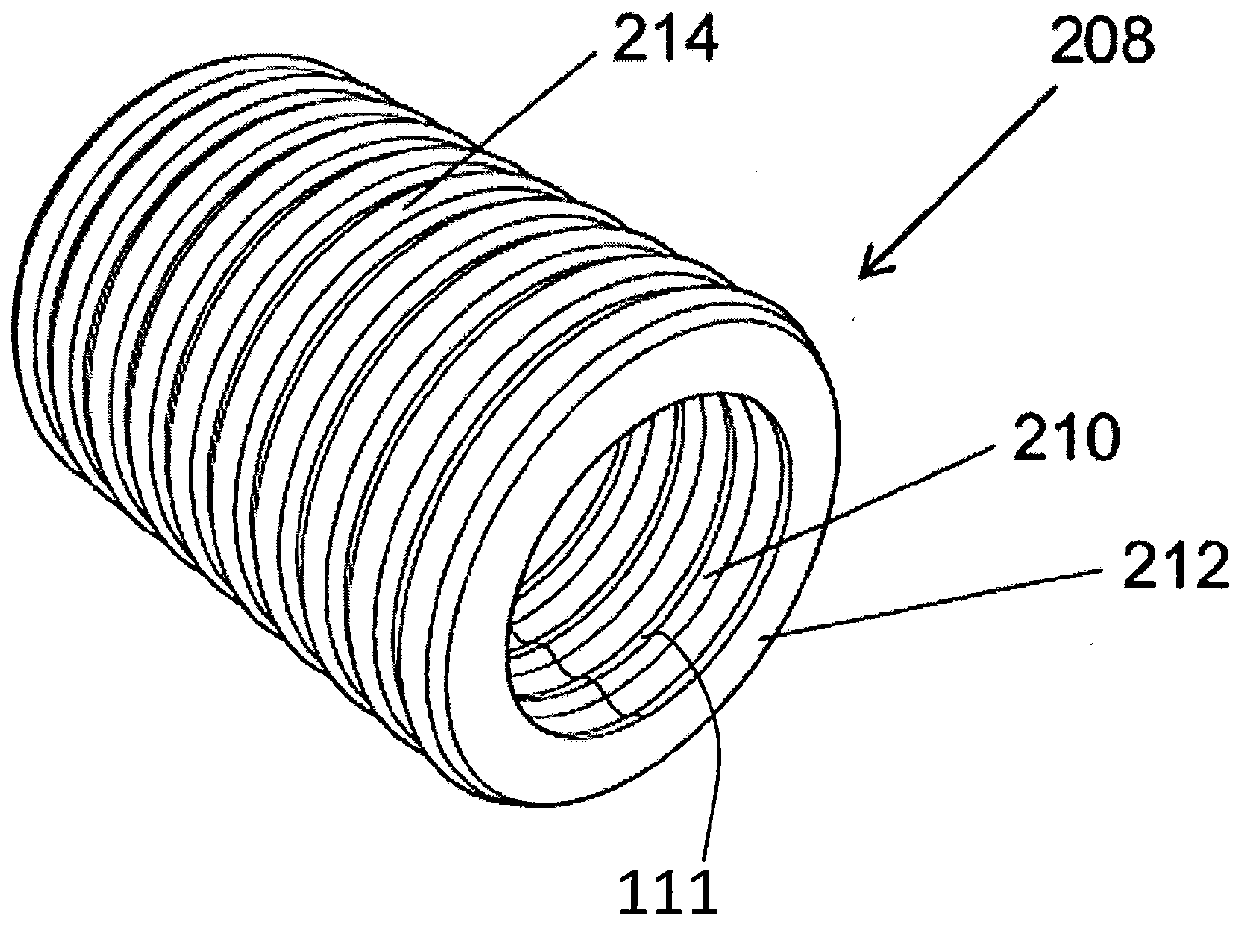

[0094] figure 1 Aspects of an embodiment of a high voltage power line 106 according to the invention are schematically shown. figure 1 In , which is a partial cross-sectional view for illustrative purposes, the high voltage power line is assembled and is thus in an assembled state. The high voltage power line includes a plurality of elongate electrical conductor segments 102 arranged side by side and in electrical contact with each other to form an inner electrical conductor 104 of the high voltage power line 106 . By its tubular overall shape, the high voltage power line 106 defines a longitudinal axis 113 . The high voltage transmission line 106 may be a high voltage direct current (HVDC) transmission line or a high voltage alternating current (HAVC) transmission line. The high voltage power transmission line comprises an elongated tubular electrical insulation device 108 arranged to receive and surround an inner electrical conductor 104 formed by electrical conductor segm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com