Laser power supply circuit board and preparation method thereof

A laser power supply and circuit board technology, which is applied in the manufacture of printed circuits, assembly of printed circuits with electrical components, printed circuits, etc., can solve problems such as circuit board damage and large circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

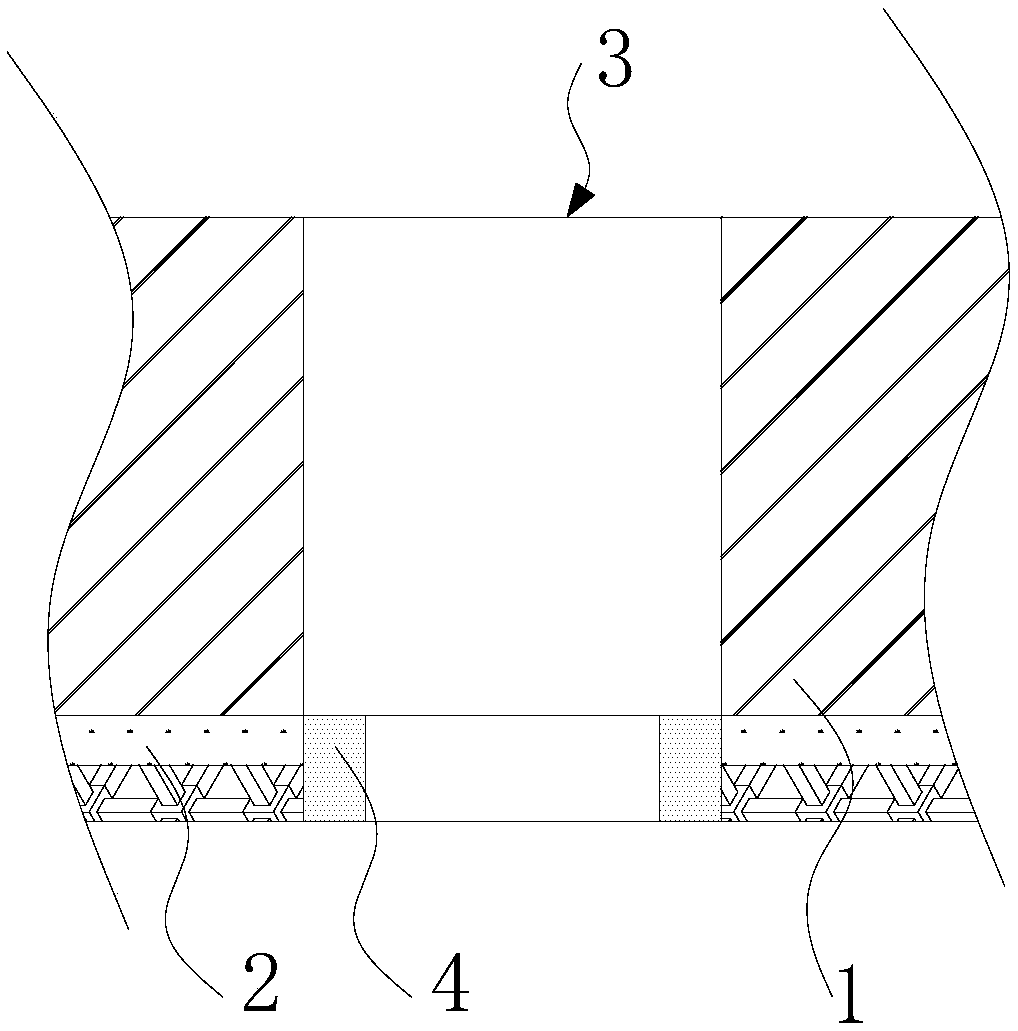

[0020] A laser power supply circuit board provided in this embodiment, such as figure 1 As shown, the circuit of the PCB board is provided with solder holes 3 and mounting holes for installing components. The solder hole is arranged in the circuit part with relatively large current, the inner diameter of the pad 4 of the solder hole 3 is 40-46mil, the inner diameter of the solder hole 3 is 55-65mil, and the solder hole 3 is filled with solder.

[0021] Further, the solder in the solder hole 3 is filled during wave soldering of each component.

[0022] Further, the inner diameter of the pad 4 of the solder hole 3 is 42-44mil, and the inner diameter of the solder hole 3 is 58-62mil.

[0023] The above-mentioned laser power supply circuit board is provided with a solder hole 3 on the circuit of the PCB board, and the solder hole 3 is filled with solder. The current flow path in the circuit is as follows: the copper skin 2 formed by sinking copper in the circuit, the solder pad 4...

Embodiment 2

[0025] The present invention also provides a method for preparing a laser power circuit board. When preparing a bare PCB, in addition to providing mounting holes for installing components, solder holes 3 are also provided on the circuit. The inner diameter of the pad 4 of the solder hole 3 is 40-46mil, and the inner diameter of the solder hole 3 is 55-65mil. When preparing the laser power circuit board, first insert the components into the mounting holes, and then solder the components by wave soldering.

[0026] In the laser power supply circuit board prepared by the above method, the circuit part with the solder hole 3 has a large current flow channel and a small resistance; it can prevent the circuit from being damaged by heat due to excessive current. The solder holes 3 are set on the circuit board in advance, and the solder holes 3 are filled with solder when the components are soldered by wave soldering. There is no need to pay other labor for filling the solder, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com